Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

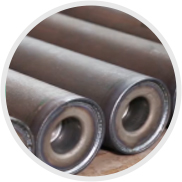

Zulu rubber lagging for conveyor pulley

The Importance of Rubber Lagging for Conveyor Pulleys

Conveyor systems are essential components in various industries, including mining, manufacturing, and logistics. They facilitate the smooth and efficient transport of goods and materials, which is crucial for meeting production deadlines and maintaining operational efficiency. One critical element in the performance of conveyor systems is the conveyor pulley, specifically its surface treatment. Rubber lagging has emerged as a preferred solution for enhancing the performance and longevity of conveyor pulleys.

Understanding Rubber Lagging

Rubber lagging refers to the application of rubber sheets or strips to the surface of conveyor pulleys. This process provides several benefits, including increased traction, reduced wear and tear, and improved protection against environmental elements. The rubber layer effectively enhances the contact between the belt and the pulley, which is vital for the efficient transfer of power.

Enhanced Traction and Reduced Slippage

One of the primary advantages of rubber lagging is its ability to improve traction between the conveyor belt and the pulley. Operating under heavy loads, the friction between the belt and the pulleys can be insufficient, resulting in slippage and loss of efficiency. Rubber lagging increases friction, ensuring that the conveyor belt remains aligned and that materials are transported effectively. This is particularly important in steep incline applications where the risk of belt slippage is greater. With enhanced traction, companies can reduce the occurrence of unexpected downtimes and improve productivity.

Protection Against Wear and Tear

Conveyor pulleys are subject to significant wear due to constant contact with the conveyor belt. Over time, this can lead to equipment failure, increased maintenance costs, and unplanned downtime. Rubber lagging serves as a protective buffer that mitigates the impact of wear and reduces the likelihood of damage. The rubber layer absorbs shock and distributes stress more evenly across the pulley surface, thereby extending the lifespan of the pulley as well as the conveyor belt.

rubber lagging for conveyor pulley

Resistance to Environmental Factors

Conveyor systems often operate in harsh conditions, including exposure to moisture, chemicals, and extreme temperatures. Rubber lagging provides a layer of protection against these environmental elements, which can degrade the metal surfaces of the pulleys over time. By using high-quality rubber lagging, companies can enhance their pulley systems' resilience against corrosion, rust, and other forms of damage caused by environmental factors. This results in lower maintenance costs and prolonged equipment life.

Noise Reduction

Another notable advantage of rubber lagging is its ability to reduce noise levels in conveyor systems. The cushioning effect of the rubber layer helps absorb vibrations, which can significantly lower operational noise. This is particularly beneficial in environments where noise reduction is essential for compliance with occupational health and safety standards. Quieter operations contribute to a more comfortable working environment for employees and reduce disturbances in adjacent areas.

Easy Installation and Maintenance

Rubber lagging is relatively easy to install, allowing for quick upgrades to existing conveyor pulley systems without significant downtime. Whether opting for hot or cold vulcanization methods, the installation process is straightforward, and the rubber can be replaced when worn out with minimal disruption to the production process. Regular inspections and maintenance of rubber lagging also ensure that any wear is addressed promptly, keeping the conveyor system efficiently running.

Conclusion

In conclusion, rubber lagging for conveyor pulleys is a practical solution that offers numerous benefits, including enhanced traction, protection against wear and environmental factors, noise reduction, and ease of maintenance. As industries continue to seek ways to optimize their operations, the adoption of rubber lagging technology is becoming increasingly vital. By investing in quality rubber lagging, companies can improve the performance, efficiency, and longevity of their conveyor systems, ultimately contributing to greater productivity and cost savings.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025