Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu roller conveyor accessories

The Importance of Roller Conveyor Accessories

In modern manufacturing and logistics, efficiency and productivity are paramount. One of the most effective ways to enhance these factors is through the implementation of roller conveyor systems. These systems allow for the effective movement of goods across various stages of production, packaging, and distribution. However, to maximize the potential of roller conveyors, the use of quality accessories is essential. This article explores the crucial role of roller conveyor accessories and how they can improve operational efficiency.

Types of Roller Conveyor Accessories

Roller conveyor accessories come in various forms, each designed to address specific needs within a conveyor system. Some of the most common accessories include

1. Guide Rails These help in keeping products aligned as they move along the conveyor. Guide rails prevent items from falling off or becoming misaligned, especially when handling irregularly shaped products.

2. Stops and Dividers These are crucial for controlling the flow of items on the conveyor. Stops can prevent items from traveling too far, while dividers can separate different products, aiding in organization and ease of access.

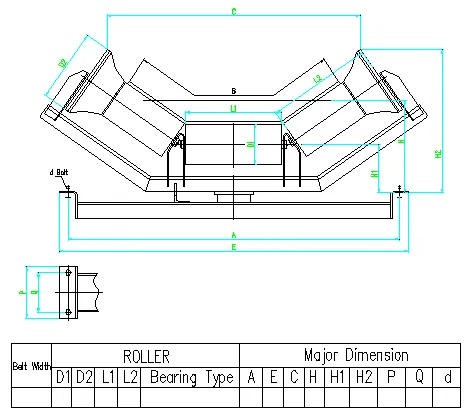

3. Roller Supports These accessories provide additional support to the conveyor system, ensuring stability and durability. Well-structured roller supports also reduce wear and tear on the conveyor, extending its lifespan.

4. Power Transfer Units In scenarios where powered roller conveyors are used, power transfer units facilitate the transfer of motion between different sections of the conveyor. This ensures a smooth and continuous flow of items throughout the system.

5. Belt Cleaners For conveyors that utilize belts, keeping the surface clean is critical. Belt cleaners remove debris that can accumulate, preventing potential damage to both the belt and the products being moved.

roller conveyor accessories

6. Sensors and Safety Equipment In an era of advanced automation, integrating sensors into roller conveyor systems enhances safety and efficiency. These sensors can detect the presence of products, triggering automatic stops or alerts if there is an obstruction.

Benefits of Using Roller Conveyor Accessories

The implementation of roller conveyor accessories offers several key benefits

- Increased Efficiency Accessories enable smoother operations, reducing downtime and eliminating bottlenecks in production lines. By keeping products organized and moving steadily, accessories enhance the overall workflow.

- Reduced Damage Properly aligned products reduce the risk of damage during transit. Accessories like guide rails and dividers help maintain product integrity by preventing collisions and falls.

- Enhanced Safety Incorporating safety accessories such as sensors and emergency stop buttons protects both employees and equipment. Safety should always be a priority in any operational setting.

- Improved Flexibility With various accessories available, roller conveyor systems can be easily customized to fit specific needs. This flexibility allows businesses to adapt quickly to changing demands or processes.

Conclusion

Roller conveyor accessories play a vital role in optimizing conveyor systems, enhancing efficiency, safety, and durability in the process. By investing in quality accessories, businesses can streamline operations, minimize risks, and ultimately improve their bottom line. As industries continue to evolve, the importance of maintaining an effective and adaptable conveyor system will only grow, making the role of accessories even more critical.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025