Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Durable PU Conveyor Rollers for Efficient Material Handling Solutions

Understanding PU Conveyor Rollers A Comprehensive Guide

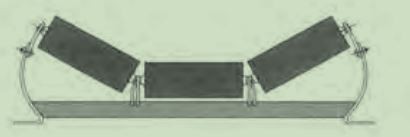

In the world of material handling and logistics, conveyor systems play a crucial role in optimizing efficiency and reducing operational costs. Among the various components that comprise these systems, conveyor rollers are essential elements that facilitate the smooth movement of goods. Among the different types of conveyor rollers available, Polyurethane (PU) conveyor rollers have gained significant popularity due to their unique properties and advantages.

What are PU Conveyor Rollers?

PU conveyor rollers are cylindrical devices that support and guide the movement of materials on a conveyor system. Made from a type of synthetic polymer known as polyurethane, these rollers offer several benefits over conventional materials like rubber or metal. The unique chemical composition of polyurethane provides excellent abrasion resistance, flexibility, and durability, making PU rollers a preferred choice for various applications in warehouses, manufacturing plants, and distribution centers.

Advantages of PU Conveyor Rollers

1. Durability One of the standout features of PU conveyor rollers is their outstanding durability. The polyurethane material does not easily wear or tear, even under heavy loads and constant use. This resilience translates to a longer lifespan for the rollers, reducing the frequency of replacements and maintenance costs.

2. Abrasion Resistance PU rollers excel in environments where friction and impact are common. Their resistance to abrasion allows them to maintain functionality even in harsh conditions, making them ideal for transporting materials that might otherwise damage standard rollers.

3. Noise Reduction Operating a conveyor system can often be accompanied by significant noise, which can be disruptive in a work environment. PU conveyor rollers are inherently more silent than metal or hard rubber rollers, contributing to a quieter operation and a more pleasant working atmosphere.

pu conveyor roller

4. Versatile Applications PU conveyor rollers can be used in a wide range of applications, from light-duty to heavy-duty conveyor systems. They are particularly suited for industries such as food and beverage, pharmaceuticals, and automotive, where hygiene and material handling efficiency are crucial.

5. Chemical Resistance Polyurethane has inherent properties that allow it to resist various chemicals and environmental factors, making it ideal for applications where exposure to oils, solvents, and other harsh substances is a concern.

Installation and Maintenance

Proper installation and maintenance of PU conveyor rollers are vital for ensuring optimal performance. Installation should be carried out by trained personnel to ensure that the rollers are positioned correctly and are aligned with the conveyor system. Regular inspections should be conducted to identify any signs of wear or damage, and any necessary adjustments should be timely to prevent further issues.

In terms of maintenance, PU rollers may require periodic cleaning to remove debris and contaminants that could hinder performance. Unlike metal rollers that may rust or corrode, PU rollers are less prone to such issues, but neglecting them can still lead to reduced efficacy over time.

Conclusion

PU conveyor rollers have established themselves as a superior choice in the realm of conveyor systems. Their durability, abrasion resistance, and versatility make them a reliable component in various industrial applications. As industries continue to seek ways to enhance efficiency and reduce operational costs, the adoption of PU conveyor rollers is likely to increase.

Investing in quality PU conveyor rollers can result in significant long-term savings, fewer interruptions in workflow, and a safer workplace environment. For those involved in the material handling industry, understanding the advantages of PU rollers is essential for making informed decisions that can drive productivity and growth.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025