Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu មករា . 24, 2025 03:39

Back to list

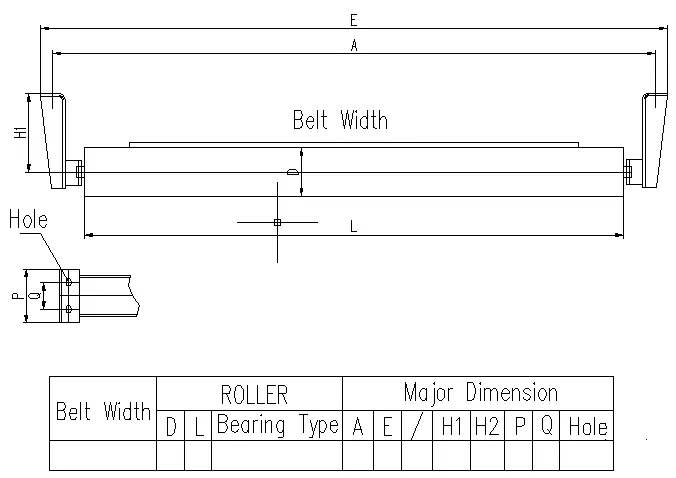

guide rollers for conveyors

Polyurethane guide rollers serve as integral components in a range of industrial applications, revered for their resilience, durability, and excellent performance under stress. As industries continue to evolve, the demand for components that offer longevity and efficiency has surged, making polyurethane guide rollers a popular choice among manufacturers and engineers. The following explores the experience, expertise, authoritativeness, and trustworthiness that polyurethane guide rollers bring to this ever-evolving industrial landscape.

In terms of trustworthiness, polyurethane guide rollers compile a transparent narrative through brand reputation and user testimonials. Manufacturers of these rollers who prioritize quality assurance and customer feedback often hold certifications that attest to their commitment to excellence. Trust is further established through rigorous testing standards that each roller must meet before reaching the market. ISO-certified manufacturers, for instance, employ stringent quality control measures, ensuring each roller adheres to specified performance metrics. Aligning with the modern industry's sustainability goals, polyurethane guide rollers also contribute positively towards eco-friendly initiatives. The production and disposal of polyurethane components generally result in a smaller carbon footprint compared to other materials, aligning with global efforts to minimize environmental impact. In conclusion, polyurethane guide rollers embody a unique combination of experience, expertise, authoritativeness, and trustworthiness, making them an indispensable asset in various industrial applications. Their robust construction not only ensures enduring performance but also promises cost-effectiveness and environment-conscious usage. By consistently exceeding the expectations set by both manufacturers and users, these guide rollers continue to shape the future of industrial engineering, driving efficiencies across numerous sectors.

In terms of trustworthiness, polyurethane guide rollers compile a transparent narrative through brand reputation and user testimonials. Manufacturers of these rollers who prioritize quality assurance and customer feedback often hold certifications that attest to their commitment to excellence. Trust is further established through rigorous testing standards that each roller must meet before reaching the market. ISO-certified manufacturers, for instance, employ stringent quality control measures, ensuring each roller adheres to specified performance metrics. Aligning with the modern industry's sustainability goals, polyurethane guide rollers also contribute positively towards eco-friendly initiatives. The production and disposal of polyurethane components generally result in a smaller carbon footprint compared to other materials, aligning with global efforts to minimize environmental impact. In conclusion, polyurethane guide rollers embody a unique combination of experience, expertise, authoritativeness, and trustworthiness, making them an indispensable asset in various industrial applications. Their robust construction not only ensures enduring performance but also promises cost-effectiveness and environment-conscious usage. By consistently exceeding the expectations set by both manufacturers and users, these guide rollers continue to shape the future of industrial engineering, driving efficiencies across numerous sectors.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS