Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

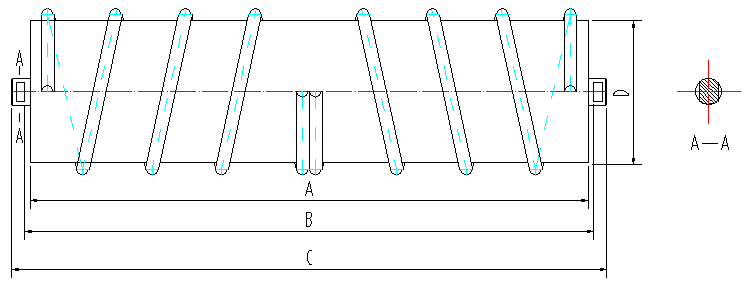

Zulu High-Performance Idler Rollers Featuring Durable Bearings for Enhanced Efficiency

Understanding Idler Rollers with Bearings A Comprehensive Guide

Idler rollers play a crucial role in various mechanical systems, particularly in conveyor systems, where they facilitate the smooth movement of materials. These components are designed to support and guide belt-driven systems while minimizing friction and wear. Among the various types of idler rollers, those equipped with bearings stand out due to their enhanced performance and durability. This article will delve into the characteristics, benefits, applications, and maintenance of idler rollers with bearings.

What are Idler Rollers?

Idler rollers are cylindrical components that are widely used in belt conveyor systems. Their primary function is to support the conveyor belt and ensure its movement along the designated path. Unlike drive rollers, which actively move the belt, idler rollers serve a passive role in the conveyance process. The use of idler rollers minimizes friction and reduces wear on the conveyor belt, extending its operational life.

The Importance of Bearings in Idler Rollers

Bearings are integral components in many mechanical systems, including idler rollers. They facilitate smooth rotation by reducing friction between moving parts. In the context of idler rollers, the incorporation of bearings significantly enhances performance. Bearings allow the roller to spin freely and evenly while supporting the weight of the material being conveyed. This ensures that the conveyor system operates efficiently with minimal energy consumption.

There are different types of bearings used in idler rollers, including ball bearings, roller bearings, and sleeve bearings. Each type has its unique characteristics and is suited for specific applications. For example, ball bearings are widely used due to their ability to support radial loads and allow for high-speed operation. On the other hand, roller bearings might be preferred in applications that require handling of heavier loads.

Benefits of Idler Rollers with Bearings

1. Reduced Friction The primary benefit of using bearings in idler rollers is the significant reduction in friction. This not only enhances the efficiency of the conveyor system but also leads to lower energy consumption.

3. Improved Load Capacity Idler rollers equipped with bearings are capable of supporting heavier loads, making them suitable for a wide range of applications, from industrial to agricultural use.

idler rollers with bearings

4. Noise Reduction Bearings help to minimize noise during operation, which is beneficial in environments where sound levels need to be controlled.

5. Versatility Idler rollers with bearings can be used in various applications, from transporting light materials to heavy bulk goods. Their adaptability makes them essential components in many industries, including mining, manufacturing, and logistics.

Applications of Idler Rollers with Bearings

Idler rollers with bearings are utilized across numerous industries due to their versatility and efficiency. Some common applications include

- Mining Used to transport mined materials, idler rollers ensure that the movement is smooth and efficient, reducing operational downtime. - Agriculture In agricultural settings, these rollers can facilitate the movement of bulk grains or feed, optimizing overall productivity. - Manufacturing In manufacturing plants, idler rollers support conveyor systems that transport finished products or raw materials, enhancing workflow management. - Logistics and Warehousing Idler rollers play a pivotal role in automated sorting systems, allowing for the rapid and efficient movement of goods.

Maintenance of Idler Rollers with Bearings

To ensure optimal performance and longevity, regular maintenance of idler rollers with bearings is necessary. Here are some maintenance tips

- Regular Inspections Periodically check the condition of both the rollers and bearings. Look for signs of wear, damage, or misalignment. - Lubrication Proper lubrication of bearings is essential to reduce friction and prevent overheating. Follow manufacturer guidelines for lubrication intervals and types. - Cleaning Keep the rollers clean and free from debris that can cause wear or jam the system. - Alignment Checks Ensure that the rollers are properly aligned to avoid unnecessary strain on the bearings.

Conclusion

Idler rollers with bearings are indispensable components in modern conveyor systems, offering numerous advantages such as reduced friction, extended lifespan, and versatility across various industries. Understanding their function, benefits, and maintenance is crucial for optimizing performance and ensuring the reliability of conveyor operations. By investing in high-quality idler rollers equipped with durable bearings, businesses can enhance their productivity and operational efficiency.