Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

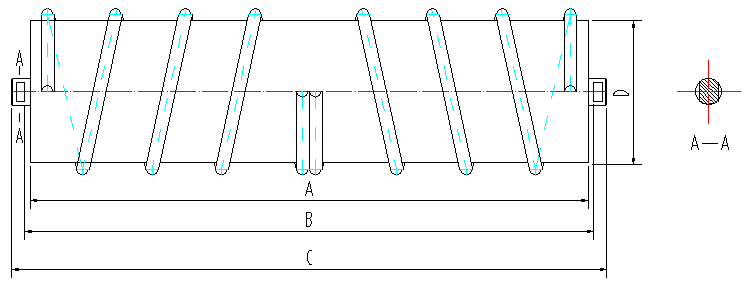

Zulu head pulley and tail pulley

Understanding Head Pulley and Tail Pulley in Conveyor Systems

In the realm of industrial machinery, conveyor systems play a crucial role in transporting materials efficiently across various stages of production. At the heart of these systems are components such as head pulleys and tail pulleys, which are essential for the seamless operation of belt conveyors. Understanding their functions and significance is vital for anyone involved in the design, maintenance, or operation of these systems.

Head Pulley The Driving Force

The head pulley, also known as the drive pulley, is located at the discharge end of the conveyor. Its primary function is to drive the belt and move the materials along the conveyor line. As the belt moves over the head pulley, it is powered by an external motor that rotates the pulley. This rotation creates friction between the pulley and the belt, enabling the transport of materials from the loading area to the desired destination.

Head pulleys are typically larger in diameter compared to tail pulleys, allowing them to maintain the necessary tension in the belt and accommodate the forces exerted during operation. They are often equipped with grooves or textured surfaces to enhance grip, ensuring that the belt remains securely in place as it wraps around the pulley. Additionally, head pulleys may incorporate features such as adjustable pulley systems or variable speed drives, enabling operators to control the speed and efficiency of the conveyor system.

Tail Pulley The Supportive Partner

head pulley and tail pulley

On the other end of the conveyor system lies the tail pulley. Positioned at the loading end, the tail pulley serves as the supporting element for the conveyor belt. While it does not drive the belt like the head pulley, it plays a crucial role in maintaining the tension and alignment of the belt throughout its operation. By providing a counterbalance to the head pulley, the tail pulley ensures that the belt operates smoothly and reduces the risk of sagging, misalignment, or potential wear and tear.

Tail pulleys are generally smaller than head pulleys and are often equipped with bearings to allow for smooth rotation. They are vital for facilitating the return movement of the belt, allowing it to loop back to the head pulley after discharging materials. In some designs, tail pulleys may also be fitted with features such as spiral steel cords or rubberized coatings, enhancing their durability and resistance to corrosion.

The Importance of Maintenance and Alignment

Both head and tail pulleys require regular maintenance to ensure optimum performance. Proper alignment is critical, as misalignment can lead to uneven wear on the belt and components, potentially resulting in significant downtime and repair costs. Regular inspection can help identify issues such as belt slippage, wear on the pulleys, or accumulated debris that can hinder performance.

In summary, head pulleys and tail pulleys are vital components of conveyor systems, each serving distinct roles in the efficiency and function of material transport. The head pulley drives the belt and facilitates material movement, while the tail pulley provides support and stability. Understanding their roles and implementing regular maintenance practices will significantly enhance the longevity and productivity of conveyor operations in industrial settings.

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025