Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Different Types of Belt Cleaners for Efficient Conveyor Maintenance and Enhanced Performance Techniques

Types of Belt Cleaners

In industrial settings, conveyor belts are pivotal for moving materials efficiently. However, over time, these belts accumulate dirt, debris, and product residue, which can hinder their performance and compromise product quality. To combat this issue, belt cleaners are employed to maintain the cleanliness of conveyor belts. This article will delve into the various types of belt cleaners, their functionalities, and the benefits they contribute to operational efficiency.

1. Primary Belt Cleaners

Primary belt cleaners are typically the first line of defense against material carryback. Positioned at the discharge point of a conveyor, these cleaners remove the majority of the material that sticks to the belt after it has loaded. The most common types of primary belt cleaners include

- Fixed Blade Cleaners These are often made of steel or rubber and operate through mechanical scraping. They are adjustable, allowing for optimal pressure against the belt. - Air Knife Cleaners Utilizing high-velocity air, air knives remove fine particles and moisture that traditional scrapers might miss. They are particularly effective for delicate materials that require a gentler touch.

2. Secondary Belt Cleaners

Secondary belt cleaners are installed further down the conveyor line to capture any remaining residue that the primary cleaners have left behind. These cleaners enhance overall cleaning efficiency and extend the lifespan of the conveyor system. Types of secondary cleaners include

- Scraper Assemblies These typically have a more flexible design than primary cleaners, allowing them to conform to the belt's surface. Made from materials like polyurethane or rubber, they are effective in minimizing wear and tear on the belt.

- Tensioned Blade Cleaners These cleaners use a tension system to keep the blades in constant contact with the belt, ensuring thorough cleaning even in fluctuating operational conditions.

3. Combination Cleaners

To maximize cleaning efficiency, many facilities utilize combination cleaners, which integrate both primary and secondary cleaning mechanisms. This dual approach significantly reduces carryback and enhances product integrity. Combination cleaners often incorporate innovative designs that allow for easy adjustments and maintenance, making them a popular choice for various industries.

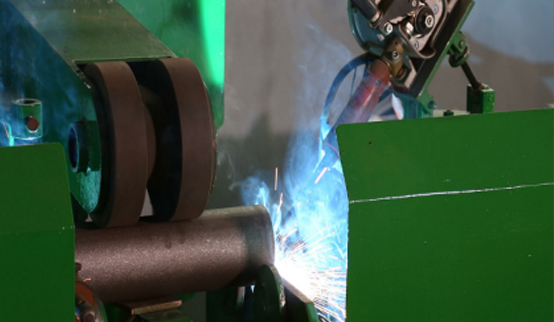

types of belt cleaners

4. Specialty Belt Cleaners

Certain applications may require specialized belt cleaning solutions tailored to specific challenges

- Washdown Cleaners In environments that demand stringent hygiene standards, such as food processing, washdown cleaners use water and cleaning agents to sanitize and clean the conveyor belt thoroughly.

- Heavy-Duty Cleaners Designed for harsh conditions and heavy loads, heavy-duty cleaners are constructed from robust materials and can withstand considerable wear, making them suitable for mining and heavy construction industries.

Benefits of Belt Cleaners

Installing appropriate belt cleaners can yield numerous benefits for operations

1. Enhanced Efficiency Clean belts reduce friction and promote smoother operation, leading to improved productivity.

2. Reduced Downtime Regular cleaning minimizes the chances of unexpected breakdowns and maintenance, allowing operations to run smoothly.

3. Improved Safety Carryback can create slip hazards in work areas. Effective cleaning reduces these risks, promoting a safer workplace.

4. Longer Equipment Lifespan By minimizing the buildup of corrosive materials, belt cleaners help to prolong the life of the conveyor system, resulting in cost savings over time.

In conclusion, selecting the right type of belt cleaner is crucial for maintaining conveyor belt performance and operational efficiency. With various options available, businesses can choose solutions that best fit their specific needs, leading to cleaner operations and enhanced productivity across industrial sectors. As conveyor systems remain a backbone of material handling, investing in effective belt cleaning technology is a smart move for any forward-thinking operation.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025