Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

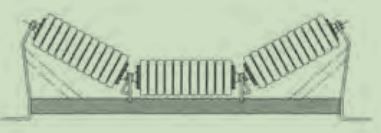

Zulu conveyor roller assembly

Understanding Conveyor Roller Assembly A Key Element in Material Handling

Conveyor systems are integral to modern manufacturing and distribution operations, providing efficient methods for moving materials from one point to another. At the heart of these systems lies a crucial component the conveyor roller assembly. This article delves into the importance, functionality, and considerations surrounding conveyor roller assemblies.

What is a Conveyor Roller Assembly?

A conveyor roller assembly consists of a series of rollers mounted on frames or supports that facilitate material movement

. These rollers can vary in size, material, and design, depending on the type of conveyor system and the materials being transported. The assembly typically includes the roller, bearing, and housing, which together ensure smooth operation and durability.Importance of Conveyor Roller Assemblies

Conveyor roller assemblies play a vital role in optimizing the efficiency of conveyor systems. They reduce friction between the conveyor belt and the transported material, allowing for smoother transitions and less wear on the belt. With high-quality roller assemblies, companies can minimize downtimes caused by maintenance or malfunctions, thereby enhancing productivity.

Additionally, the design of these rollers impacts the overall performance of the conveyor system. Various types of rollers, including impact rollers, return rollers, and guide rollers, are designed to handle specific functions within the conveyor system. Impact rollers, for example, absorb the shock from heavy loads, while return rollers help support the belt on its return journey.

conveyor roller assembly

Choosing the Right Conveyor Roller Assembly

Selecting the appropriate conveyor roller assembly involves several factors. First and foremost, the load capacity is crucial; the roller must be able to support the weight of the materials being transported without failing. Similarly, the dimensions of the roller – including its diameter and length – should match the specifications of the conveyor system to ensure compatibility and performance.

The material of the roller is another essential consideration. Rollers can be made from various materials including plastic, steel, and aluminum. The choice of material often depends on the environment in which the conveyor operates. For example, stainless steel may be preferred in food processing environments due to its resistance to corrosion and ease of cleaning.

Furthermore, maintenance requirements should be evaluated. Roller assemblies with sealed bearings can reduce the need for regular lubrication, whereas those with open bearings may demand more frequent maintenance but could be easier to replace.

Conclusion

In summary, conveyor roller assemblies are fundamental components that contribute significantly to the efficiency and reliability of conveyor systems. Their role in reducing friction, supporting loads, and maintaining the integrity of material transport cannot be overstated. Companies seeking to optimize their operations must carefully consider the specifications, materials, and maintenance needs of their conveyor roller assemblies. By investing in high-quality components and making informed choices, businesses can achieve smoother operations, reduced downtimes, and ultimately, higher productivity levels in their material handling processes.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025