Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor pulley price

Understanding Conveyor Pulley Prices Factors and Insights

In the industrial world, conveyor systems play an essential role in ensuring the efficient movement of materials. At the heart of these systems lies the conveyor pulley, a critical component that contributes significantly to the overall functionality and durability of conveyor belts. As industries continue to expand and adapt, understanding the pricing of conveyor pulleys becomes increasingly important for businesses looking to optimize their operations.

The Importance of Conveyor Pulleys

Conveyor pulleys are devices used to control the movement of the conveyor belt, either by providing tension or guiding the belt along a designated path. They can be categorized into several types, including drive pulleys, return pulleys, and bend pulleys, each serving distinct functions within the conveyor system. As such, the quality and type of pulley selected can have a profound impact on the efficiency and longevity of the conveyor system.

Factors Affecting Conveyor Pulley Prices

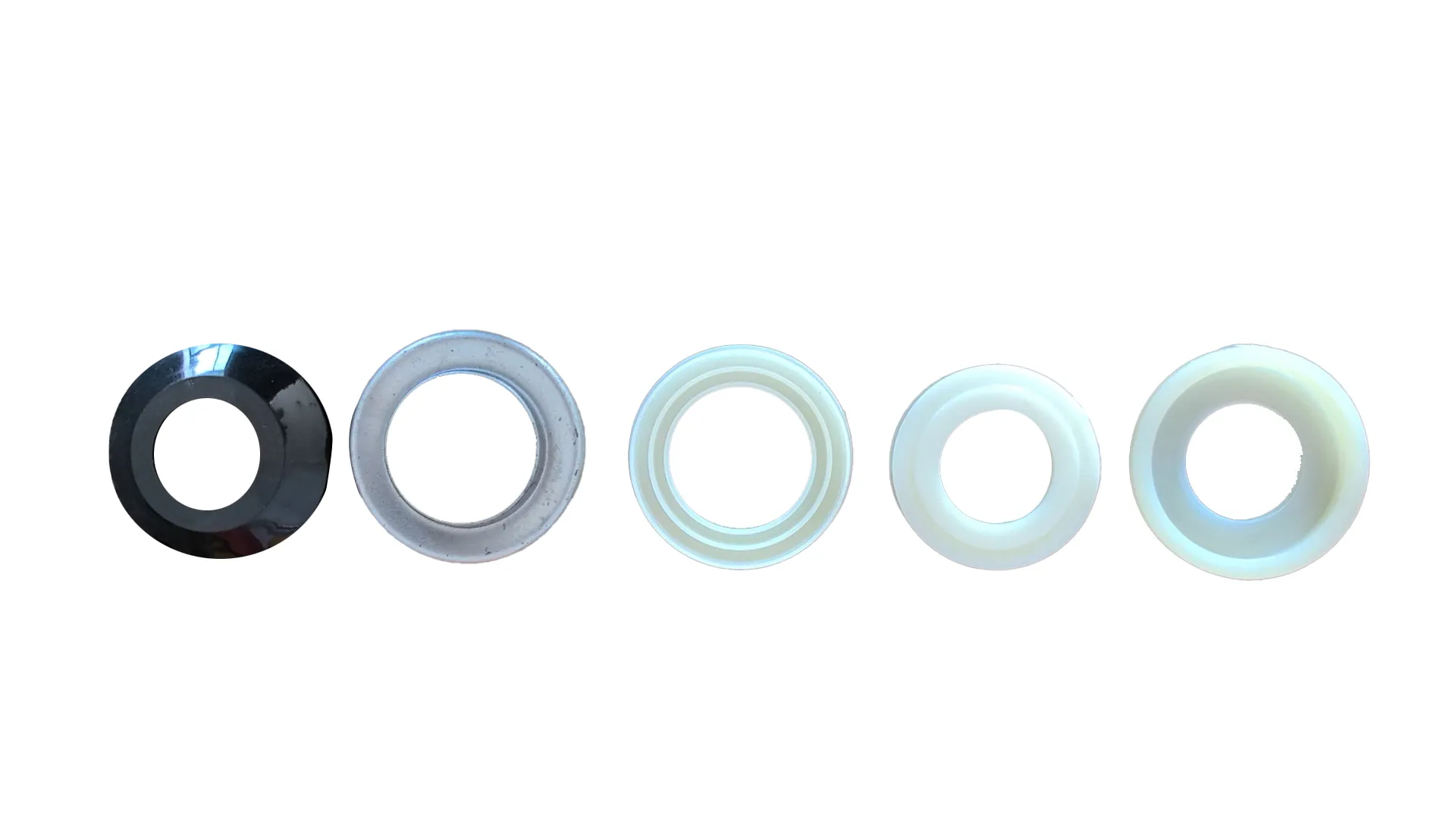

1. Material Composition The materials used in pulley manufacturing can significantly influence price. Common materials include steel, aluminum, and plastic, each offering different benefits in terms of weight, corrosion resistance, and strength. Steel pulleys, while often more expensive, provide robustness suitable for heavy-duty applications, which can justify the higher price point.

2. Size and Dimensions Conveyor pulleys come in various sizes to accommodate different conveyor systems. Larger and more complex pulleys typically come at a higher cost due to the increased material and manufacturing requirements. It’s essential for businesses to assess their specific needs when selecting pulley sizes to avoid overpaying for unnecessary features.

conveyor pulley price

3. Manufacturing Processes How pulleys are manufactured also plays a crucial role in determining their prices. Custom-built or specialized pulleys generally cost more than standard models due to the extra labor and resources required for production. Companies may wish to consider pre-fabricated options if they are looking to reduce costs without compromising quality.

4. Supplier Reputation The reputation of the supplier can influence pricing as well. Established suppliers with a track record of quality and reliability may charge more for their products, but the assurance of durability and performance might offset the expense in the long run.

5. Market Demand Fluctuations in the industrial market can lead to variations in conveyor pulley prices. When demand is high and supply is limited, prices tend to rise. Conversely, during periods of lower demand, companies might find better deals on pulleys. Keeping an eye on market trends is advisable for organizations looking to make cost-effective purchases.

6. Additional Features Some pulleys come with advanced features, such as specialized coatings for enhanced wear resistance, integrated monitoring systems, or features designed for specific applications (e.g., food production). While these enhancements can add to the cost, they can also improve performance and lifespan, ultimately offering a better return on investment.

Conclusion

In summary, the price of conveyor pulleys can vary widely based on several factors, including material, size, manufacturing processes, and market dynamics. As businesses continue to demand efficient and reliable conveyor systems, understanding these factors will empower them to make informed purchasing decisions. Investing in the right conveyor pulley is not only about cost but also about enhancing operational efficiency, reducing downtime, and ensuring a smooth workflow. As such, companies should approach the procurement process with careful consideration and a clear understanding of their specific needs to achieve optimal results in their operations.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025