Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu មករា . 14, 2025 10:34

Back to list

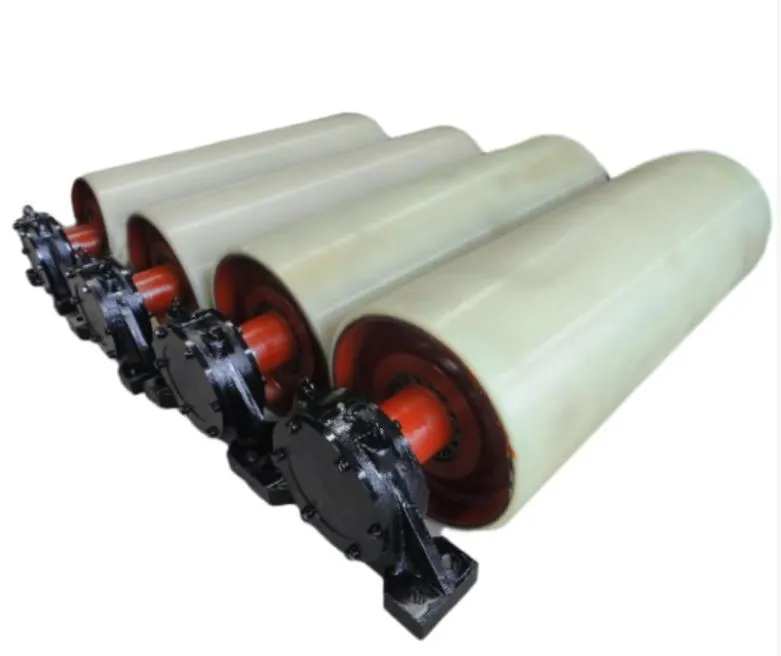

conveyor lagging

Conveyor lagging is a critical component in the world of material handling, often overlooked but essential for anyone aiming to enhance the efficiency and longevity of their conveyor systems. Integrating high-quality lagging into your conveyor systems not only improves performance but significantly reduces downtime, which directly translates to cost savings for your operation.

As an authoritative voice in the field, I regularly educate clients on the importance of maintaining their conveyor lagging. Regular inspections and timely replacement are paramount to maintaining the conveyor's performance. A worn-out lagging can lead to slippage problems, resulting in inefficient operations and increased wear and tear on the belt, ultimately culminating in unplanned downtime. Thus, having a maintenance plan in place enhances the trustworthiness of your operations, ensuring that your conveyor systems run smoothly and efficiently. Trust is also built through transparency in the materials and methods used for lagging. Providing clear, detailed information about the materials' origin and the processes utilized in their installation is crucial. Clients should have access to certifications and compliance documents that attest to the quality and safety of the lagging products they are investing in. This not only builds confidence but also reinforces long-term business relationships. In conclusion, conveyor lagging is much more than a simple accessory in a conveyor system. It's a crucial element that, when expertly chosen and applied, can boost the entire system's efficiency, reliability, and lifespan. For those serious about optimizing their material handling processes, investing in the right conveyor lagging and a knowledgeable team to maintain it is a strategic necessity. Partnering with professionals who provide expert advice and stand by the quality and performance of their products can make all the difference in achieving success in your operations.

As an authoritative voice in the field, I regularly educate clients on the importance of maintaining their conveyor lagging. Regular inspections and timely replacement are paramount to maintaining the conveyor's performance. A worn-out lagging can lead to slippage problems, resulting in inefficient operations and increased wear and tear on the belt, ultimately culminating in unplanned downtime. Thus, having a maintenance plan in place enhances the trustworthiness of your operations, ensuring that your conveyor systems run smoothly and efficiently. Trust is also built through transparency in the materials and methods used for lagging. Providing clear, detailed information about the materials' origin and the processes utilized in their installation is crucial. Clients should have access to certifications and compliance documents that attest to the quality and safety of the lagging products they are investing in. This not only builds confidence but also reinforces long-term business relationships. In conclusion, conveyor lagging is much more than a simple accessory in a conveyor system. It's a crucial element that, when expertly chosen and applied, can boost the entire system's efficiency, reliability, and lifespan. For those serious about optimizing their material handling processes, investing in the right conveyor lagging and a knowledgeable team to maintain it is a strategic necessity. Partnering with professionals who provide expert advice and stand by the quality and performance of their products can make all the difference in achieving success in your operations.

Latest news

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025

OUR PRODUCTS