Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor idler roller manufacturers

Exploring the World of Conveyor Idler Roller Manufacturers

In the intricate realm of industrial manufacturing and logistics, conveyor systems play a pivotal role in ensuring the efficient movement of materials and products. A crucial component of these conveyor systems is the idler roller, which helps support and guide the conveyor belt, ultimately contributing to the efficient operation of the entire system. In this article, we delve into the world of conveyor idler roller manufacturers, focusing on their significance, selection criteria, and the latest industry trends.

The Functionality of Idler Rollers

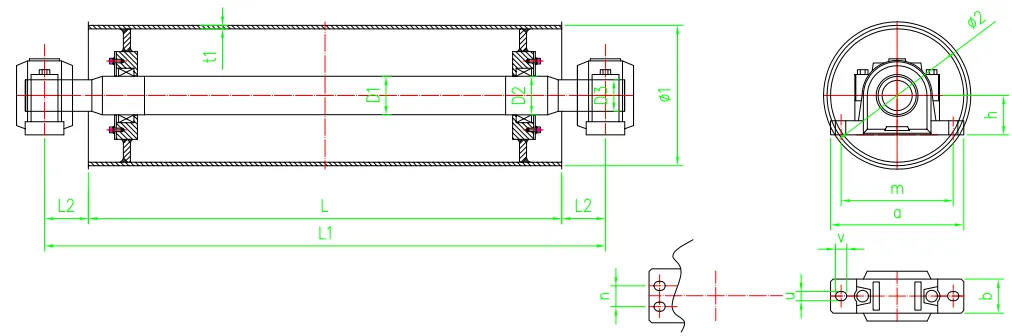

Idler rollers are cylindrical components that are strategically placed along a conveyor belt. They serve multiple purposes supporting the weight of the belt and its cargo, maintaining the belt's tension, and facilitating the smooth movement of materials. The design of these rollers can significantly affect the performance of the conveyor system; hence, choosing the right manufacturer is essential.

Importance of Quality in Manufacturing

When it comes to selecting a conveyor idler roller manufacturer, quality should be the foremost consideration. High-quality rollers are made from durable materials that can withstand heavy loads and extreme conditions. Manufacturers often employ advanced materials such as high-strength steel, rubber, or polyurethane to create rollers that are resistant to wear, corrosion, and other forms of damage. This durability directly contributes to decreased maintenance costs and increased system efficiency.

Key Selection Criteria

1. Material and Construction Look for manufacturers that utilize high-quality materials. The construction techniques employed can also affect the roller's lifespan. Proper sealing and bearing arrangements are critical to ensure longevity and reliability.

2. Customization Options Different industries have unique requirements. A reputable manufacturer should offer customization options to accommodate various sizes, weights, and specific application needs.

3. Industry Experience Manufacturers with years of experience are more likely to understand the intricacies of various industries. Their expertise can provide valuable insights into selecting the right idler rollers for specific applications.

conveyor idler roller manufacturers

4. Certification and Standards Ensure that potential manufacturers adhere to international quality standards. Certifications such as ISO 9001 can indicate a commitment to quality and consistency.

5. Customer Support A reliable manufacturer will offer excellent customer support, providing guidance on installation, maintenance, and troubleshooting.

Trends in Conveyor Idler Roller Manufacturing

The conveyor roller manufacturing industry is evolving, driven by technological advancements and changing market needs. Some notable trends include

- Sustainability Increasing environmental concerns are pushing manufacturers to adopt sustainable practices. This includes using eco-friendly materials and implementing energy-efficient manufacturing processes.

- Automation and Smart Technology The integration of smart technology in conveyor systems is on the rise. Manufacturers are beginning to incorporate sensors and IoT capabilities in rollers to monitor performance and predict maintenance needs, leading to reduced downtime.

- Innovative Designs Modern roller designs focus on reducing friction and improving energy efficiency. Advanced roller geometries are being developed to enhance belt tracking and minimize wear on both rollers and belts.

- Globalization As industries expand globally, manufacturers are catering to a wider audience. This has led to increased competition, driving innovation and better pricing strategies.

Conclusion

Selecting the right conveyor idler roller manufacturer can have a profound impact on the efficiency and sustainability of your operations. As the demand for high-quality, durable, and innovative solutions grows, manufacturers continue to refine their products to meet these expectations. By considering factors such as material quality, customization options, and industry experience, businesses can make informed decisions that ultimately enhance their productivity and reduce operational costs. The future of conveyor systems is ripe with possibilities, and the role of idler rollers in this evolution cannot be overstated. As you delve into your conveyor system needs, remember that choosing the right manufacturer is the first step towards achieving operational excellence.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025