Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor components manufacturers

The Importance of Conveyor Components Manufacturers in Modern Industry

In today's fast-paced manufacturing and logistics environments, the efficiency of operations is often dictated by the effectiveness of conveyor systems. These systems are integral to the movement of materials, products, and goods within a facility, acting as the backbone of production lines and distribution centers. Behind the success of any conveyor system lies a critical player conveyor components manufacturers. These manufacturers provide the essential parts that allow conveyor systems to function optimally.

The Role of Conveyor Components

Conveyor components are the building blocks of any conveyor system, comprised of various elements such as belts, rollers, pulleys, motors, and more. Each component plays a vital role in ensuring that materials are moved smoothly and efficiently. For example, conveyor belts facilitate the transport of goods across different elevations and distances, while rollers and pulleys assist in the movement and redirection of these belts.

Without high-quality components, conveyor systems can face significant challenges, including increased maintenance costs, downtime, and potentially hazardous working conditions. Reliability and durability in conveyor components are therefore paramount for manufacturers to minimize interruptions and protect their bottom line.

Manufacturing Innovation

The landscape of conveyor component manufacturing has evolved dramatically with the advent of modern technology. Innovations such as automation, robotics, and advanced materials science have transformed how these components are designed and produced. Manufacturers are now able to create components that are not only more robust and longer-lasting but are also tailored to specific industry applications, whether it be for food processing, automotive, or warehousing.

Additionally, the rise of 3D printing technology is revolutionizing the prototyping and production of conveyor parts

. This method allows for rapid iteration and customization, enabling manufacturers to respond quickly to unique customer requirements without the extensive lead times associated with traditional manufacturing processes.Sustainability in Manufacturing

conveyor components manufacturers

As industries worldwide place a greater emphasis on sustainability, conveyor components manufacturers are also adapting their practices. The use of eco-friendly materials, energy-efficient manufacturing processes, and recycling initiatives is becoming increasingly common. This not only reduces the environmental footprint of producing conveyor components but also appeals to customers who are steering their operations towards greener solutions.

Moreover, sustainable practices in manufacturing are not only about compliance with regulations but also about enhancing the brand's reputation. Companies that proactively incorporate sustainability are often viewed more favorably by consumers and stakeholders alike.

Choosing the Right Manufacturer

When selecting a conveyor components manufacturer, companies should consider several key factors. First, it is important to assess the quality of the components they provide. Quality assurance is critical, ensuring that parts can withstand operational stresses and are less likely to fail.

Additionally, manufacturers that offer technical support and after-sales service can add significant value to their products. A responsive support team is essential for addressing any issues that may arise during installation or operation, ensuring that the conveyor system remains functional for as long as possible.

Customization capabilities are another important aspect to consider. Every facility has unique needs, and the ability of a manufacturer to provide tailored solutions can make a significant difference. Companies should inquire about the manufacturer's ability to work closely with clients to understand their specific requirements and provide appropriate solutions.

Conclusion

In conclusion, conveyor components manufacturers play a crucial role in the efficiency and effectiveness of modern industrial operations. As manufacturing and logistics continue to evolve, these manufacturers must remain at the forefront of innovation, sustainability, and quality to meet the demands of their customers. By selecting the right partners in conveyor components manufacturing, businesses can enhance their productivity, reduce downtime, and ultimately improve their competitive edge in the market. The success of a conveyor system is often a direct reflection of the quality and reliability of its components, making these manufacturers invaluable in the quest for operational excellence.

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

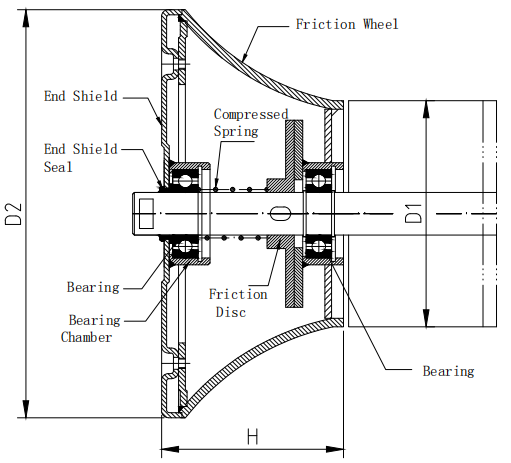

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025