Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Efficient Design of Concave Guide Rollers for Enhanced Material Handling Systems

The Importance of Concave Guide Rollers in Material Handling

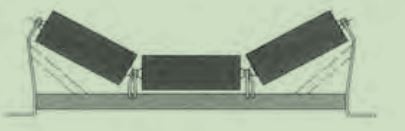

In the realm of material handling and conveyor systems, the design and functionality of guide rollers play a crucial role in ensuring smooth operation and efficiency. Among these, concave guide rollers are particularly significant due to their unique shape and benefits they offer in various industrial applications.

Concave guide rollers are designed with a grooved surface that is concavely shaped, allowing them to hold and guide items securely as they move through conveyor systems. This design prevents items from slipping off the sides, which is especially important for irregularly shaped or non-uniform products. The concave surface creates a natural cradle that guides materials along a predetermined path, reducing the risk of jams or misalignment that can hinder productivity.

One of the major advantages of using concave guide rollers is their ability to accommodate a variety of product shapes and sizes. Whether transporting boxes, bags, or loose materials, these rollers can adapt to the needs of different operations. By improving stability and control, concave guide rollers help maintain a constant flow of materials, ultimately enhancing the overall efficiency of the transport system.

concave guide roller

Additionally, concave guide rollers contribute to reducing wear and tear on both the products being transported and the conveyor system itself. The smooth surface and proper alignment provided by these rollers minimize friction, which can lead to product damage or conveyor breakdowns. This not only prolongs the life of the equipment but also decreases maintenance costs, making them a sound investment for any facility.

Another key feature is their versatility in installation and configuration. Concave guide rollers can be integrated into existing conveyor systems with relative ease, making them suitable for retrofitting older equipment. They are available in various materials, including rubber and polyurethane, which can absorb impact and further protect conveyed products from damage.

In conclusion, concave guide rollers are a vital component of modern material handling systems. Their innovative design maximizes stability and efficiency during transport, making them an ideal choice for various industries, such as manufacturing, logistics, and distribution. By opting for concave guide rollers, businesses can ensure the smooth operation of their systems, reduce maintenance costs, and enhance the safety and reliability of their material handling processes. As industries continue to evolve, the importance of such specialized components will only grow, making concave guide rollers an essential aspect of any effective conveyor solution.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025