Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu components of a conveyor system

Components of a Conveyor System An Overview

Conveyor systems are integral to modern manufacturing and logistics, enabling the efficient movement of goods and materials across various production environments

. These systems come in various configurations and are used in a plethora of industries, from automotive to food production. Understanding the components of a conveyor system is essential for designing, maintaining, and optimizing these systems for maximum efficiency.At the heart of any conveyor system is the conveyor belt, which is designed to transport materials from one point to another. Conveyor belts can be made from various materials such as rubber, metal, or plastic, each suited for specific applications. For instance, rubber belts are often used for their durability, while plastic belts are popular in food processing due to their ease of cleaning. The width and length of a conveyor belt can vary depending on the types of materials being moved and the space available in a facility.

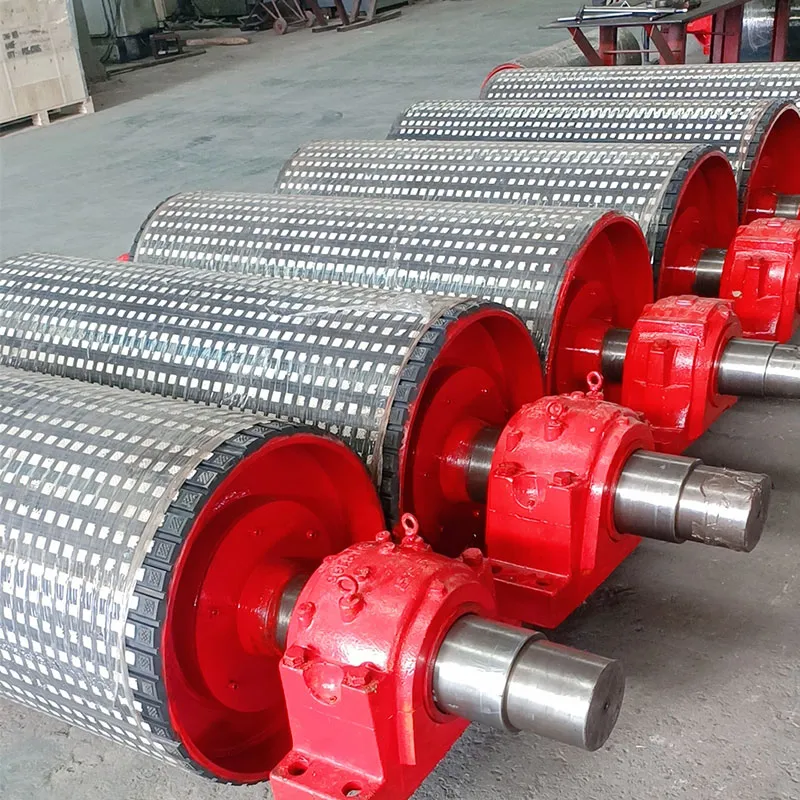

Another crucial component of a conveyor system is the drive mechanism. This includes the motor and pulleys that provide the necessary power to move the belt. The choice of motor can greatly impact the performance of the conveyor system. For example, electric motors are commonly used for their efficiency, while pneumatic systems may be employed in environments where electricity poses a risk. Drive mechanisms must be carefully selected based on the load requirements and the speed needed for operations.

Supporting the belt and creating a stable pathway for materials are the conveyor frames. These frames can be constructed from various materials, including steel, aluminum, and plastic. A robust frame is essential for maintaining the integrity of the conveyor system, ensuring it can handle the weight of the materials being transported. Furthermore, frames need to be designed with adjustments for tensioning the belt, which is crucial for preventing slippage and ensuring smooth operation.

components of a conveyor system

Another important component of conveyor systems is the idler rollers, which are used to support the belt and distribute the load across the entire surface. These rollers reduce friction and assist in the smooth running of the belt, ultimately increasing the system's efficiency. Depending on the application, idlers can be flat or grooved, and their placement is strategically determined to ensure optimal performance.

In certain situations, additional components enable more complex material handling capabilities. For instance, systems may include chutes, which direct materials to specific locations, and transfer stations, which facilitate the movement of goods from one conveyor to another. Sensors and control systems also play a vital role in modern conveyor systems, allowing for automation and real-time monitoring of operations. These technologies enhance efficiency by optimizing speed, reducing downtime, and ensuring that materials are delivered where they are needed when they are needed.

Finally, maintenance components, such as tensioning devices and alignment systems, are crucial for ensuring the longevity of a conveyor. Regular checking and adjustment of these elements can prevent costly breakdowns and extend the service life of the system.

In conclusion, conveyor systems are comprised of several key components that work together to facilitate the efficient movement of materials. From the conveyor belt to the drive mechanism, supporting frames, idler rollers, and additional systems for automation, each part plays a critical role in the overall functionality. Understanding these components is fundamental for anyone involved in the design, operation, or maintenance of conveyor systems, ensuring that they can adapt to the ever-evolving needs of industry. With the right configuration and maintenance, conveyor systems can significantly enhance productivity and logistical efficiency across various sectors.

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025