Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

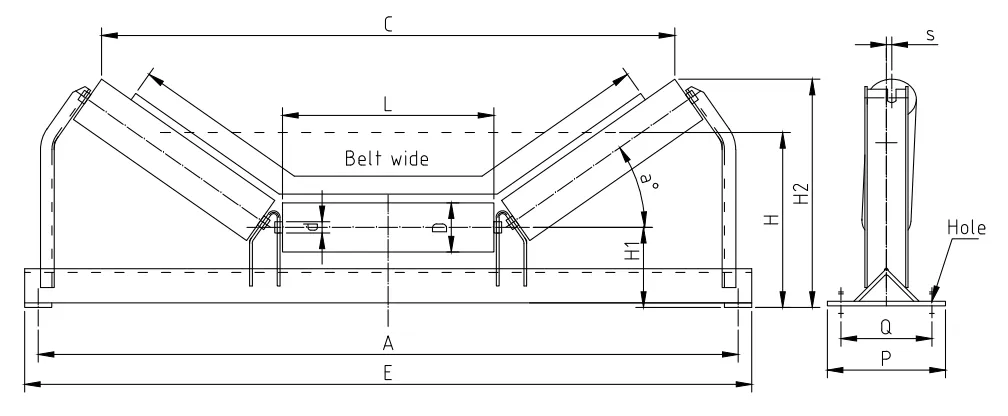

Zulu carrying idler frame

Understanding Carrying Idler Frames in Conveyor Systems

In the realm of material handling and conveyor systems, the efficiency and reliability of transporting materials are paramount. One critical component often overlooked is the carrying idler frame. This structural element plays a significant role in supporting the conveyor belt and ensuring that materials are moved from one point to another with minimal friction and maximum stability.

What is a Carrying Idler Frame?

A carrying idler frame is designed to hold idler rolls, which support the weight of the conveyor belt along its length. These frames serve as the backbone of the conveyor system, providing the necessary structure to maintain the belt's trajectory and to support the materials being transported. Typically made from durable materials such as steel or aluminum, carrying idler frames must withstand significant loads and environmental impacts while ensuring proper alignment and spacing of the idlers.

Importance of Carrying Idler Frames

1. Support Weight Load The primary function of a carrying idler frame is to support the weight of the materials on the conveyor belt. As the belt traverses various angles and elevations, the idler frames ensure that the load is distributed evenly, minimizing stress on the belt itself.

2. Maintain Belt Alignment Proper alignment of the conveyor belt is essential to prevent premature wear and tear. Carrying idler frames help in maintaining the correct trajectory of the belt, reducing misalignment issues that can lead to material spillage and operational inefficiencies.

3. Reduce Friction The design of carrying idler frames and the positioning of the idler rolls help in reducing friction between the belt and the frame. Lower friction translates to less energy consumption, enhancing the overall efficiency of the conveyor system.

4. Facilitate Maintenance A well-designed carrying idler frame simplifies maintenance tasks. By allowing easy access to idlers for inspections and replacements, conveyor operators can ensure that the system remains in optimal working condition, thus extending the lifespan of both the idler rolls and the conveyor belt.

carrying idler frame

Design Considerations

When designing carrying idler frames, several factors must be taken into account

- Material Selection The choice of material for the frame impacts its strength and durability. Typically, frames are made from high-strength steel to tolerate heavy loads, while corrosion-resistant coatings may be applied to enhance longevity.

- Load Capacity The design must consider the maximum load the system will carry, including any dynamic factors such as acceleration or deceleration during operation.

- Modularity Modular designs can facilitate easier adjustments and replacements. This flexibility is particularly essential in sectors where conveyor configurations may change over time.

- Environmental Factors Depending on the operating environment, frames may need to be designed to withstand extreme temperatures, moisture, or high levels of dust and debris.

Conclusion

Carrying idler frames are a crucial yet often underestimated component of conveyor systems. Their role in supporting the belt, maintaining alignment, reducing friction, and facilitating maintenance is essential for the efficient functioning of material handling operations. Understanding the significance of this component enables businesses to optimize their conveyor designs, leading to improved operational efficiency and reduced costs in the long run. As industries continue to evolve, integrating robust and efficient carrying idler frames will play a vital role in the overall success of material handling systems.

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025