Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Belt Cleaning Solutions for Enhanced Conveyor Performance and Maintenance Efficiency

Understanding Belt Scrapers An Essential Component in Material Handling

Belt scrapers, also known as belt cleaners, are crucial equipment in various industries, particularly in material handling and processing. Their primary function is to clean the surfaces of conveyor belts, ensuring operational efficiency and mitigating the risks associated with material carryback. This article delves into the significance, types, and benefits of belt scrapers, providing insights for professionals in the field.

The Importance of Belt Scrapers

Conveyor belts are instrumental in transporting materials across different sectors, including mining, agriculture, and manufacturing. However, as materials are transferred, some residue can adhere to the belt's surface, leading to problems such as reduced belt traction, increased wear, and potential operational hazards. This carryback can result in equipment inefficiencies, increased maintenance costs, and environmental concerns due to spillage. Here, belt scrapers come into play.

By adhering to the belt's surface and removing the material that clings to it, belt scrapers help maintain clean working environments and ensure that the conveyor system operates effectively. They also contribute to prolonging the life of the conveyor belt, as well-maintained belts are less prone to damage and will require less frequent replacements.

Types of Belt Scrapers

Belt scrapers come in various designs to cater to different types of conveyor systems and material characteristics. The primary types include

1. Primary Belt Scrapers These are typically installed at the discharge point of the conveyor. They are designed to handle substantial amounts of carryback material and provide aggressive cleaning action to remove residue effectively. 2. Secondary Belt Scrapers Installed further down the belt, secondary scrapers serve as a supplementary cleaning mechanism. They work to eliminate any remaining material that the primary scraper might have missed, providing thorough cleaning. 3. Specialty Scrapers These scrapers are created for unique applications, such as dealing with sticky or abrasive materials that would be difficult to clean with standard scrapers. Specialty scrapers may use soft materials to avoid damaging the conveyor belt while still achieving effective cleaning.

belt scraper

4. Universal Scrapers Designed for versatility, universal scrapers can be adjusted to fit various belt widths and configurations, making them ideal for facilities that utilize multiple types of conveyors.

Benefits of Using Belt Scrapers

The implementation of belt scrapers offers various benefits that extend beyond mere cleaning. Some of these advantages include

- Enhanced Efficiency By minimizing carryback, belt scrapers ensure that materials are effectively transported, reducing waste and improving productivity. - Cost Savings Regular cleaning reduces wear and tear on conveyor components, leading to lower maintenance and replacement costs over time. - Environmental Compliance By minimizing spillage and material loss, belt scrapers help companies adhere to regulatory standards and promote environmentally responsible operations. - Safety Improvements A clean conveyor system reduces the risk of slip and fall accidents, contributing to a safer work environment for employees.

Maintenance of Belt Scrapers

To ensure optimal performance, regular inspection, and maintenance of belt scrapers are essential. This includes checking the alignment, tension, and wear of the blades. Over time, the blades may need to be replaced or adjusted to maintain their effectiveness, as worn-out scrapers can lead to inefficient cleaning.

Conclusion

In conclusion, belt scrapers are indispensable tools in ensuring the smooth operation of conveyor systems across various industries. Their ability to keep belts clean not only enhances efficiency but also fosters safety and environmental responsibility. Understanding the different types and benefits of belt scrapers empowers organizations to select the right solutions, ensuring that they maintain a competitive edge in their respective markets. As industries continue to evolve, the role of belt scrapers remains crucial in the realm of material handling.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

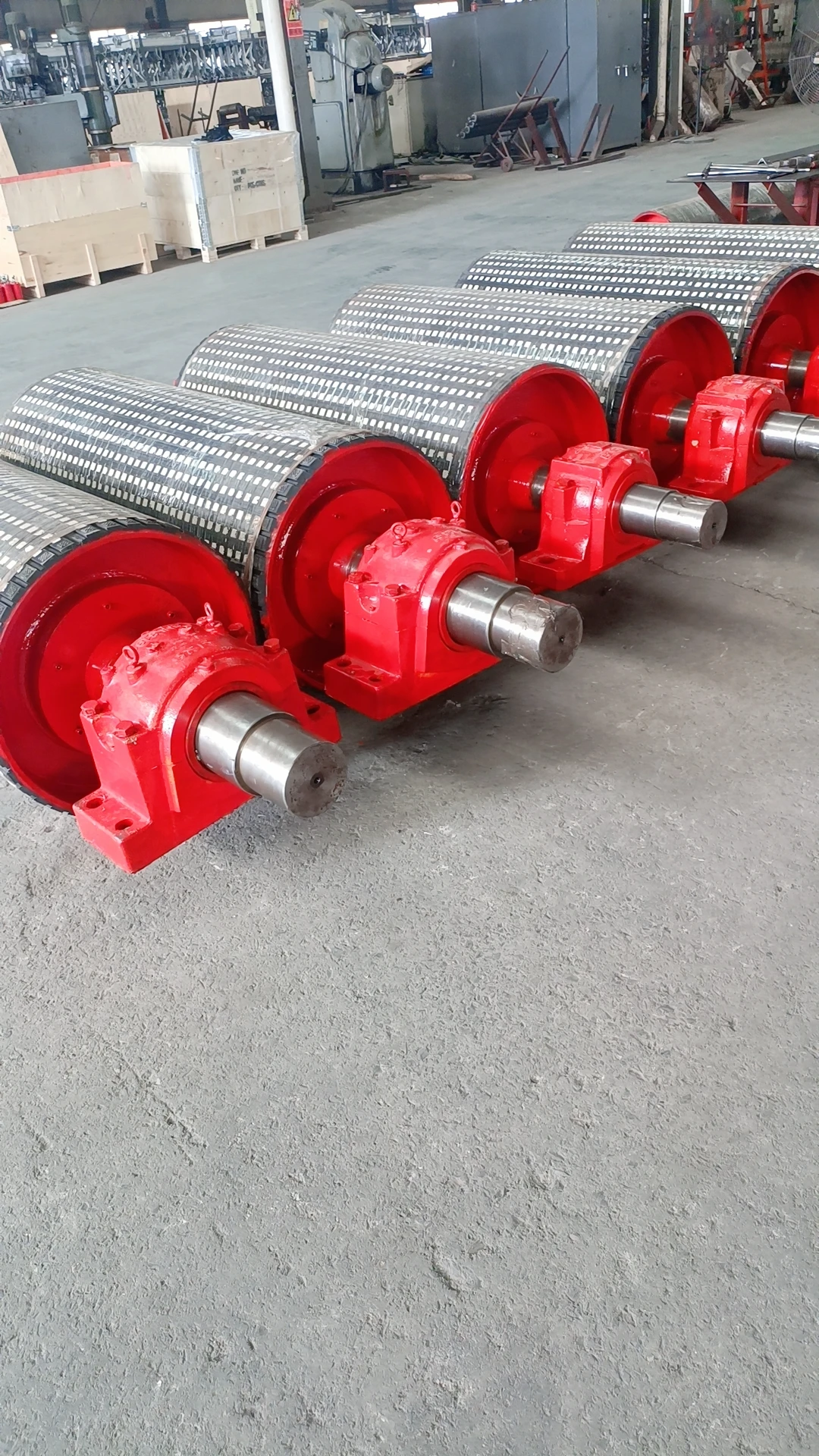

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025