Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Қаң . 14, 2025 11:21

Back to list

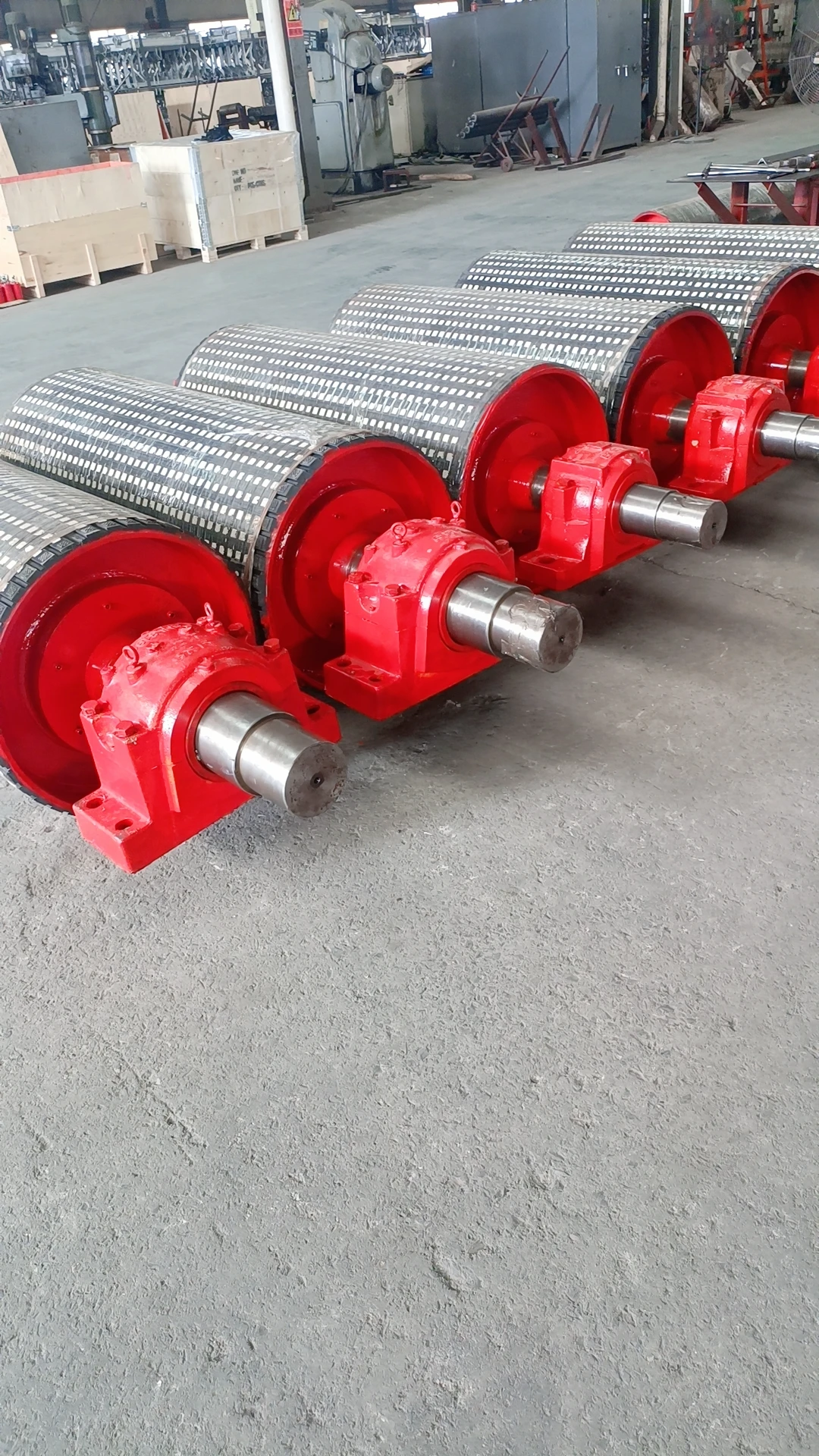

types of conveyor pulley

Conveyor pulleys are pivotal components within conveyor systems, facilitating the movement and direction of belts across various applications. Understanding the different types of conveyor pulleys can provide a significant advantage to those seeking optimized, efficient material handling solutions. Drawing from years of experience, we explore the major types of conveyor pulleys, focusing on their unique characteristics and applications.

Magnetic Pulleys are specialized components used in recycling and waste management sectors. These pulleys can attract and separate ferrous materials from non-ferrous ones. Embedded with magnets, they ensure efficient segregation, critical for processes looking to optimize recycling rates. The authority of magnetic pulleys is undisputed in their niche sector, where precision in material handling is paramount. Snub Pulleys serve to increase the tension in the belt system, ensuring the belt stays aligned and functions efficiently. Positioned closely adjacent to the drive or tail pulley, snub pulleys increase the wrap angle and maximize contact space, which leads to enhanced traction. This detailed attention to belt tensioning is vital for high-speed and high-throughput systems, making snub pulleys a trusted choice in advanced conveyor setups. Bend Pulleys, primarily used to redirect conveyor belts, are crucial in changing the direction of the belt within complex systems. Although they do not contribute to driving power, they play an essential role in maintaining the proper alignment of conveyors that need to navigate tight or angled paths. Bend pulleys are engineered to facilitate smooth transitions and are an authoritative choice in conveyor systems that demand intricate routing. In conclusion, each type of conveyor pulley serves a specific function within industrial operations, defined by its design and material characteristics. Recognizing the appropriate pulley type to use is fundamental to creating a robust, efficient conveyor system. Leveraging the right pulley not only boosts operational efficiency but also ensures longevity and reliability, key factors that uphold industry standards for material handling excellence.

Magnetic Pulleys are specialized components used in recycling and waste management sectors. These pulleys can attract and separate ferrous materials from non-ferrous ones. Embedded with magnets, they ensure efficient segregation, critical for processes looking to optimize recycling rates. The authority of magnetic pulleys is undisputed in their niche sector, where precision in material handling is paramount. Snub Pulleys serve to increase the tension in the belt system, ensuring the belt stays aligned and functions efficiently. Positioned closely adjacent to the drive or tail pulley, snub pulleys increase the wrap angle and maximize contact space, which leads to enhanced traction. This detailed attention to belt tensioning is vital for high-speed and high-throughput systems, making snub pulleys a trusted choice in advanced conveyor setups. Bend Pulleys, primarily used to redirect conveyor belts, are crucial in changing the direction of the belt within complex systems. Although they do not contribute to driving power, they play an essential role in maintaining the proper alignment of conveyors that need to navigate tight or angled paths. Bend pulleys are engineered to facilitate smooth transitions and are an authoritative choice in conveyor systems that demand intricate routing. In conclusion, each type of conveyor pulley serves a specific function within industrial operations, defined by its design and material characteristics. Recognizing the appropriate pulley type to use is fundamental to creating a robust, efficient conveyor system. Leveraging the right pulley not only boosts operational efficiency but also ensures longevity and reliability, key factors that uphold industry standards for material handling excellence.

Latest news

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025

OUR PRODUCTS