Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Gen . 25, 2025 02:42

Back to list

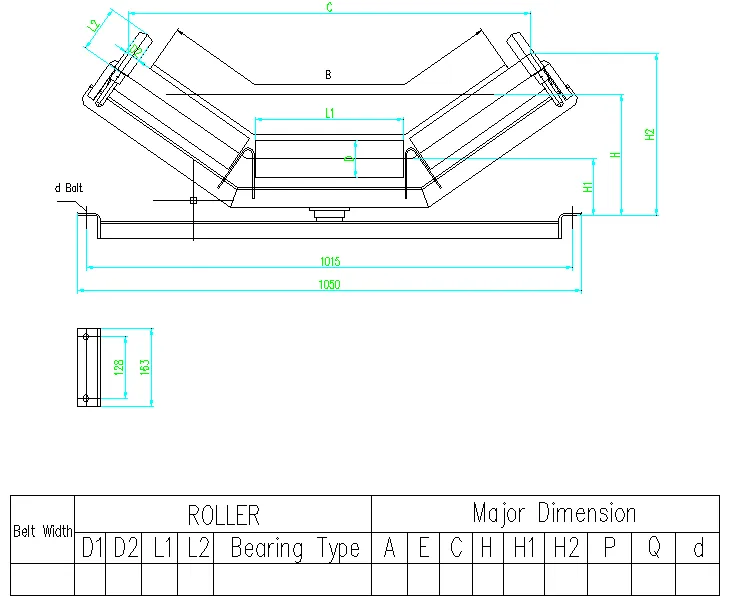

rubber impact roller

Rubber impact rollers are revolutionizing the way industries handle material transportation and processing with their robust construction and unparalleled performance. These specialized rollers, typically used in mining, construction, and manufacturing sectors, are engineered to absorb shock, reduce vibration, and mitigate the adverse effects of material impact.

4. Trustworthiness Through Proven Results Customer testimonials and case studies highlight the transformative impact of integrating rubber impact rollers into material handling systems. Mining companies, for instance, report not only reduced maintenance and operational costs but also improved safety for their workforce. This trust in rubber impact rollers is reinforced by comprehensive warranties and excellent customer support provided by manufacturers, solidifying the product’s reputation in the market. 5. Innovative Engineering and Design The design of rubber impact rollers incorporates advanced engineering principles to enhance their functionality. Features such as adjustable elasticity, optimal rubber thickness, and superior shock absorption are tailored based on specific operational requirements. This customization potential ensures that each roller setup is ideally suited to handle the unique challenges of different industrial environments. 6. Enhancing Efficiency and Sustainability In the era of sustainability, rubber impact rollers present an eco-friendly alternative to traditional metal rollers. They are quieter, reducing noise pollution in industrial facilities, and their longevity contributes to less frequent replacements, thereby decreasing material waste. Moreover, rubber, as a material, offers better recycling potential compared to metal components, aligning with global environmental goals. In conclusion, rubber impact rollers are not just components in a conveyor system; they're catalysts for efficiency, cost-reduction, and sustainability. Their contribution to the operational success of industries is underscored by their innovative design, proven performance, and the trust they garner among industrial players. Adopting rubber impact rollers is a strategic move toward modernizing and optimizing material handling processes in today's competitive industrial landscape.

4. Trustworthiness Through Proven Results Customer testimonials and case studies highlight the transformative impact of integrating rubber impact rollers into material handling systems. Mining companies, for instance, report not only reduced maintenance and operational costs but also improved safety for their workforce. This trust in rubber impact rollers is reinforced by comprehensive warranties and excellent customer support provided by manufacturers, solidifying the product’s reputation in the market. 5. Innovative Engineering and Design The design of rubber impact rollers incorporates advanced engineering principles to enhance their functionality. Features such as adjustable elasticity, optimal rubber thickness, and superior shock absorption are tailored based on specific operational requirements. This customization potential ensures that each roller setup is ideally suited to handle the unique challenges of different industrial environments. 6. Enhancing Efficiency and Sustainability In the era of sustainability, rubber impact rollers present an eco-friendly alternative to traditional metal rollers. They are quieter, reducing noise pollution in industrial facilities, and their longevity contributes to less frequent replacements, thereby decreasing material waste. Moreover, rubber, as a material, offers better recycling potential compared to metal components, aligning with global environmental goals. In conclusion, rubber impact rollers are not just components in a conveyor system; they're catalysts for efficiency, cost-reduction, and sustainability. Their contribution to the operational success of industries is underscored by their innovative design, proven performance, and the trust they garner among industrial players. Adopting rubber impact rollers is a strategic move toward modernizing and optimizing material handling processes in today's competitive industrial landscape.

Next:

Latest news

-

The Unrivaled Performance of Polyurethane Pulleys in Industrial ApplicationsNewsAug.25,2025

-

The Critical Role of Drum Lagging in Conveyor SystemsNewsAug.25,2025

-

Navigating Industrial Efficiency: The Critical Role of Conveyor PulleysNewsAug.25,2025

-

InIntroduction to Advanced Pulley Lagging SolutionsNewsAug.25,2025

-

Industry Trends in Pulley Lagging TechnologyNewsAug.25,2025

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

OUR PRODUCTS