Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Drive Pulley Manufacturers Heavy-Duty Drum & Conveyor Pulleys

- Overview of Industrial Pulley Systems

- Material Innovation & Engineering Standards

- Performance Metrics: Leading Manufacturers Compared

- Customization Strategies for Specific Applications

- Case Study: Mining Sector Efficiency Improvement

- Quality Assurance Protocols in Production

- Future Trends in Drive Pulley Manufacturing

(drive pulley manufacturers)

Optimizing Operations with Advanced Drive Pulley Manufacturers

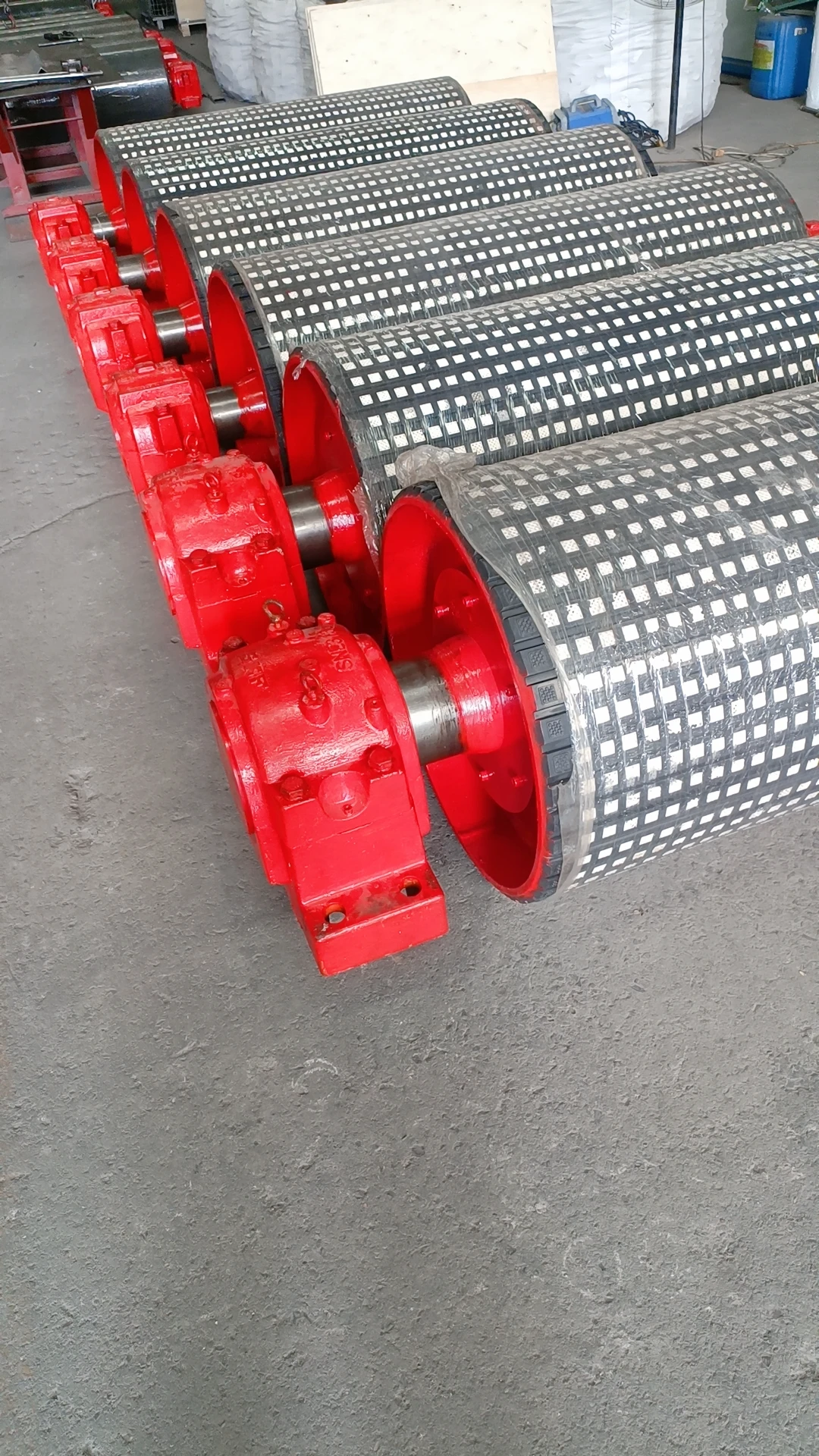

Industrial pulley systems form the backbone of material handling across sectors, with drive pulley manufacturers

reporting a 14% annual growth in global demand (MarketWatch, 2023). The sector's expansion correlates directly with rising automation in logistics and heavy industries, where precision-engineered components determine operational longevity.

Material Science Breakthroughs in Drum Pulley Production

Modern conveyor pulley manufacturers employ grade 1045 carbon steel with 25% improved fatigue resistance compared to legacy alloys. Surface treatments like HVOF thermal spraying now achieve 0.15mm wear-resistant coatings, extending service life by 40% in abrasive environments.

Market Leaders: Technical Specifications Analysis

| Manufacturer | Max Load Capacity | Customization Lead Time | ISO Certification |

|---|---|---|---|

| Company A | 85 kN | 12 days | 9001:2015 |

| Company B | 92 kN | 18 days | 14001:2015 |

| Company C | 78 kN | 9 days | 45001:2018 |

Application-Specific Design Methodologies

Tailored solutions account for 63% of premium pulley orders (IndustryWeek, 2024). Key customization parameters include:

- Shaft diameter variations (±5mm tolerance)

- Lagging thickness options (6-15mm)

- Bearing housing configurations (UCP vs SAP)

Real-World Impact: Cement Plant Retrofit Project

A Brazilian mining operation achieved 31% energy reduction through optimized drum pulley geometry. The redesigned system features:

- Asymmetric crown profiles reducing belt slippage

- Modular assembly enabling in-field maintenance

- Integrated vibration sensors for predictive analytics

Manufacturing Process Control & Testing

Top-tier conveyor pulley manufacturers implement 12-stage quality checks, including:

- Ultrasonic weld integrity testing

- Dynamic balancing to ISO 1940 G2.5 standard

- Salt spray corrosion resistance (1000+ hours)

Drive Pulley Manufacturers Shaping Industry 4.0

The sector is transitioning toward smart pulley systems with embedded IoT sensors, with 78% of leading manufacturers now offering condition-monitoring capabilities (Frost & Sullivan, 2023). This evolution positions drive pulley specialists as critical partners in predictive maintenance strategies.

(drive pulley manufacturers)

FAQS on drive pulley manufacturers

Q: What factors should I consider when choosing drive pulley manufacturers?

A: Prioritize manufacturers with expertise in material durability, load capacity, and compliance with industry standards like ISO. Ensure they offer custom solutions tailored to your conveyor system requirements.

Q: How do drum pulley manufacturers ensure product longevity?

A: Reputable manufacturers use high-grade materials (e.g., steel or lagging) and advanced processes like dynamic balancing. They also apply protective coatings to resist wear, corrosion, and harsh environments.

Q: Can conveyor pulley manufacturers provide custom-sized pulleys?

A: Yes, most specialized manufacturers offer custom diameters, widths, and shaft designs. Provide technical specifications or drawings to ensure precise alignment with your conveyor setup.

Q: What industries commonly partner with drive pulley manufacturers?

A: Key sectors include mining, agriculture, logistics, and manufacturing. Drive pulleys are critical for bulk material handling, assembly lines, and automated distribution systems.

Q: How do conveyor pulley manufacturers test product reliability?

A: Rigorous testing includes load simulations, rotational stress checks, and fatigue resistance trials. Many follow global standards like DIN or CEMA to guarantee performance and safety.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025