Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jun . 20, 2024 00:33

Back to list

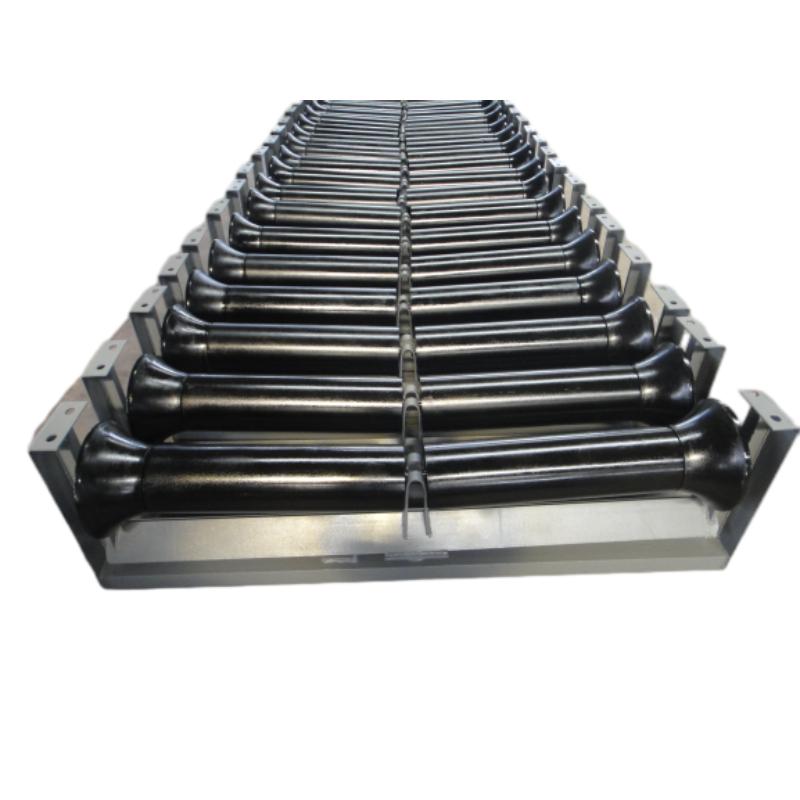

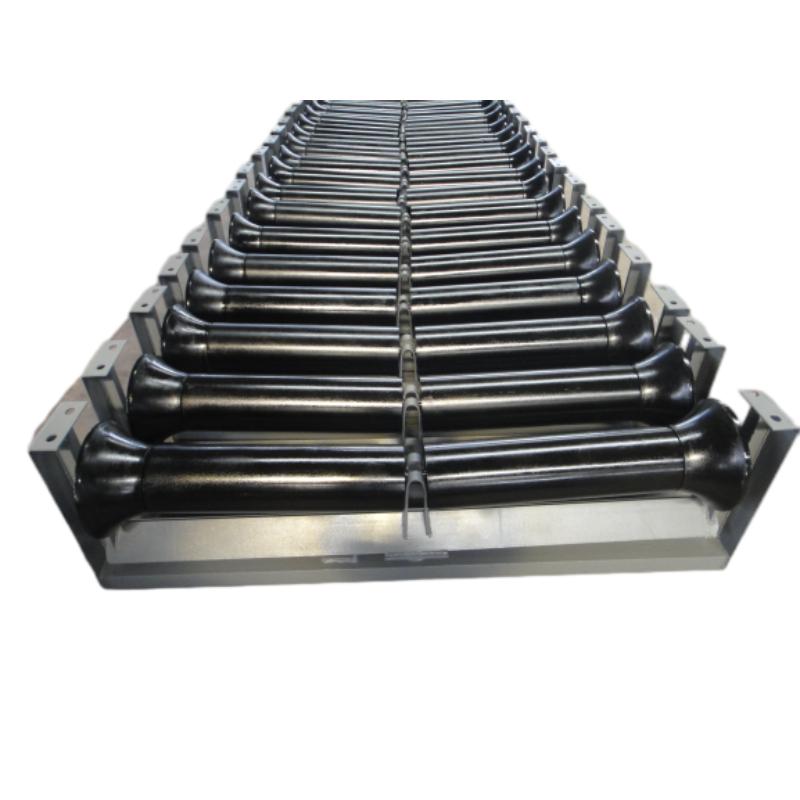

Adjust the tension on the tail pulley.

The Vital Role of the Tail Pulley Take-up System in Modern Industry

In the realm of industrial machinery and conveyor systems, the tail pulley take-up mechanism holds a significant position, playing an essential role in ensuring optimal performance and efficiency. This component, often overlooked, is the cornerstone of numerous operations across various sectors, from manufacturing plants to material handling facilities.

The tail pulley, also known as the return pulley, is a crucial element in conveyor systems. It's the point where the conveyor belt makes its return journey after completing the load-carrying cycle. The 'take-up' part of the system refers to the mechanism designed to adjust the tension on the belt, ensuring it remains taut and centered, thereby preventing slippage and potential damage.

The take-up device, whether it be a manual or automatic system, is strategically placed near the tail pulley. Its primary function is to compensate for belt stretch, which occurs naturally over time due to continuous usage and environmental factors. By adjusting the belt tension, the take-up system maintains the belt's correct alignment, minimizing wear and tear, and extending the lifespan of both the belt and the entire conveyor system.

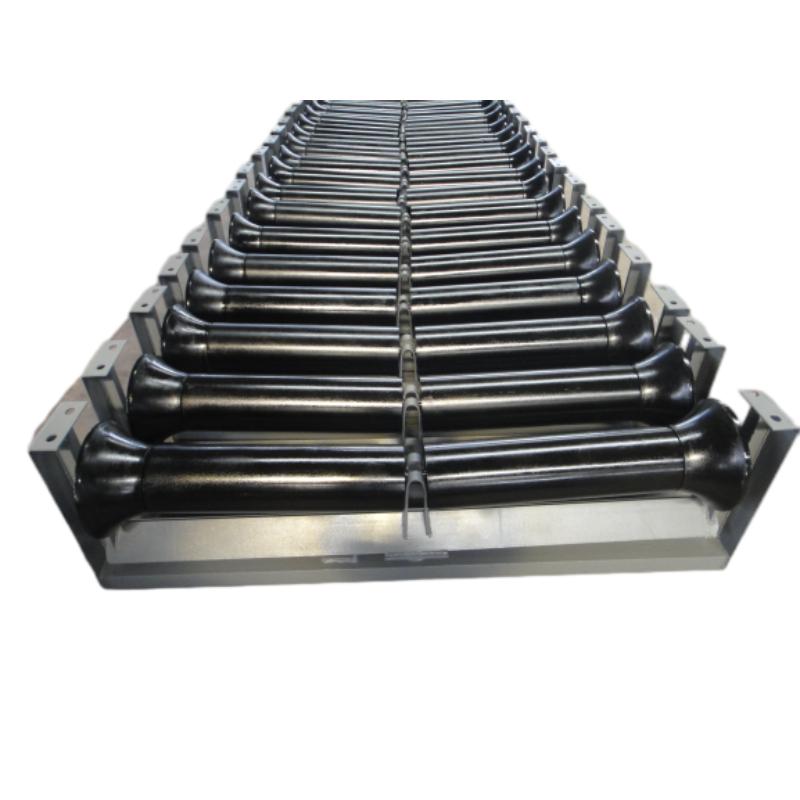

Moreover, the tail pulley take-up system also contributes to the overall safety of the operation. A loose belt can cause hazardous conditions, including belt mistracking, which could lead to accidents or equipment failure. On the other hand, a belt that's too tight can put unnecessary stress on bearings and motors, potentially leading to premature failure On the other hand, a belt that's too tight can put unnecessary stress on bearings and motors, potentially leading to premature failure On the other hand, a belt that's too tight can put unnecessary stress on bearings and motors, potentially leading to premature failure On the other hand, a belt that's too tight can put unnecessary stress on bearings and motors, potentially leading to premature failure

On the other hand, a belt that's too tight can put unnecessary stress on bearings and motors, potentially leading to premature failure On the other hand, a belt that's too tight can put unnecessary stress on bearings and motors, potentially leading to premature failure tail pulley take up. Therefore, the take-up mechanism acts as a safety net, mitigating these risks and ensuring smooth, uninterrupted workflow.

In modern industry, advancements in technology have led to the development of more sophisticated tail pulley take-up systems. These incorporate sensors and automated controls, allowing for real-time monitoring and adjustments, further enhancing efficiency and reducing maintenance needs.

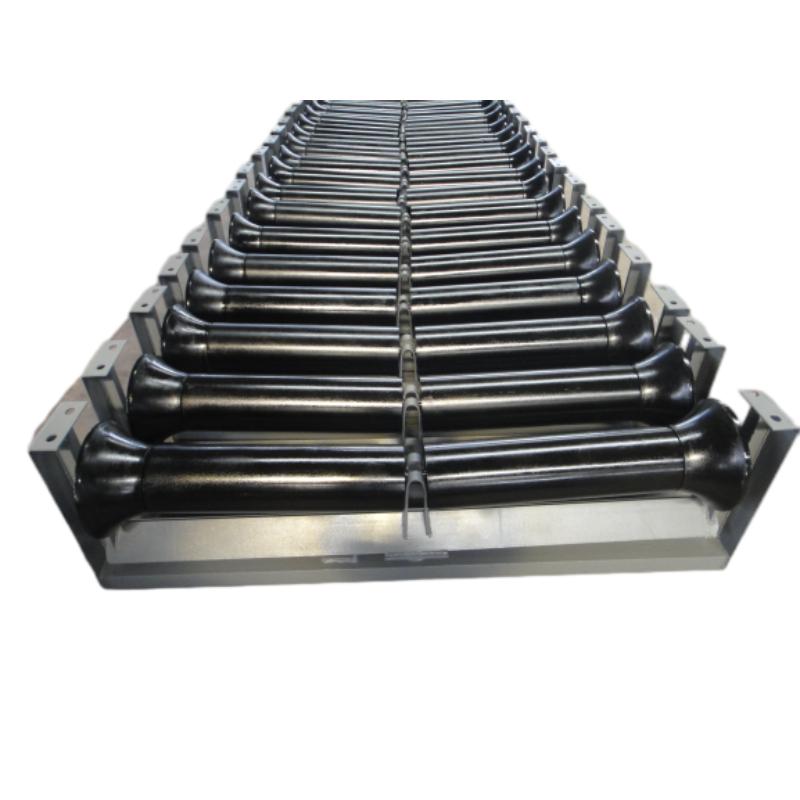

Despite its seemingly simple function, the tail pulley take-up system's impact on productivity and operational reliability cannot be overstated. It's a testament to the importance of considering every component in a complex system, no matter how small or seemingly insignificant. Each piece, from the mighty motor to the humble tail pulley take-up, contributes to the overall efficiency and success of industrial processes.

In conclusion, the tail pulley take-up system is not just a mechanical feature; it's a critical component that ensures the smooth running of conveyor operations. Its role in maintaining belt tension, preventing accidents, and optimizing efficiency underscores its significance in today's fast-paced industrial environment. As we continue to innovate and refine our industrial processes, the importance of understanding and appreciating the tail pulley take-up system only grows.

tail pulley take up. Therefore, the take-up mechanism acts as a safety net, mitigating these risks and ensuring smooth, uninterrupted workflow.

In modern industry, advancements in technology have led to the development of more sophisticated tail pulley take-up systems. These incorporate sensors and automated controls, allowing for real-time monitoring and adjustments, further enhancing efficiency and reducing maintenance needs.

Despite its seemingly simple function, the tail pulley take-up system's impact on productivity and operational reliability cannot be overstated. It's a testament to the importance of considering every component in a complex system, no matter how small or seemingly insignificant. Each piece, from the mighty motor to the humble tail pulley take-up, contributes to the overall efficiency and success of industrial processes.

In conclusion, the tail pulley take-up system is not just a mechanical feature; it's a critical component that ensures the smooth running of conveyor operations. Its role in maintaining belt tension, preventing accidents, and optimizing efficiency underscores its significance in today's fast-paced industrial environment. As we continue to innovate and refine our industrial processes, the importance of understanding and appreciating the tail pulley take-up system only grows.

On the other hand, a belt that's too tight can put unnecessary stress on bearings and motors, potentially leading to premature failure On the other hand, a belt that's too tight can put unnecessary stress on bearings and motors, potentially leading to premature failure

On the other hand, a belt that's too tight can put unnecessary stress on bearings and motors, potentially leading to premature failure On the other hand, a belt that's too tight can put unnecessary stress on bearings and motors, potentially leading to premature failure tail pulley take up. Therefore, the take-up mechanism acts as a safety net, mitigating these risks and ensuring smooth, uninterrupted workflow.

In modern industry, advancements in technology have led to the development of more sophisticated tail pulley take-up systems. These incorporate sensors and automated controls, allowing for real-time monitoring and adjustments, further enhancing efficiency and reducing maintenance needs.

Despite its seemingly simple function, the tail pulley take-up system's impact on productivity and operational reliability cannot be overstated. It's a testament to the importance of considering every component in a complex system, no matter how small or seemingly insignificant. Each piece, from the mighty motor to the humble tail pulley take-up, contributes to the overall efficiency and success of industrial processes.

In conclusion, the tail pulley take-up system is not just a mechanical feature; it's a critical component that ensures the smooth running of conveyor operations. Its role in maintaining belt tension, preventing accidents, and optimizing efficiency underscores its significance in today's fast-paced industrial environment. As we continue to innovate and refine our industrial processes, the importance of understanding and appreciating the tail pulley take-up system only grows.

tail pulley take up. Therefore, the take-up mechanism acts as a safety net, mitigating these risks and ensuring smooth, uninterrupted workflow.

In modern industry, advancements in technology have led to the development of more sophisticated tail pulley take-up systems. These incorporate sensors and automated controls, allowing for real-time monitoring and adjustments, further enhancing efficiency and reducing maintenance needs.

Despite its seemingly simple function, the tail pulley take-up system's impact on productivity and operational reliability cannot be overstated. It's a testament to the importance of considering every component in a complex system, no matter how small or seemingly insignificant. Each piece, from the mighty motor to the humble tail pulley take-up, contributes to the overall efficiency and success of industrial processes.

In conclusion, the tail pulley take-up system is not just a mechanical feature; it's a critical component that ensures the smooth running of conveyor operations. Its role in maintaining belt tension, preventing accidents, and optimizing efficiency underscores its significance in today's fast-paced industrial environment. As we continue to innovate and refine our industrial processes, the importance of understanding and appreciating the tail pulley take-up system only grows. Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS