Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu return idler bracket

Understanding the Return Idler Bracket Design and Functionality

In the realm of mechanical engineering and design, the Return Idler Bracket plays a crucial role, particularly in systems that involve conveyor belts, cable systems, and various types of machinery. The Return Idler Bracket not only supports the weight of the returning elements but also ensures the stability and efficiency of the entire system. This article will explore the significance, design considerations, and practical applications of the Return Idler Bracket.

What is a Return Idler Bracket?

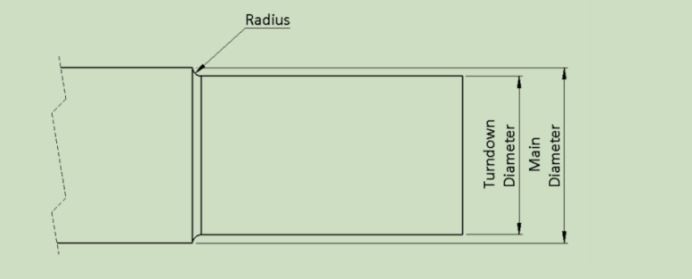

The Return Idler Bracket is a structural component designed to hold idler rollers or pulleys in place. These rollers are essential for guiding belts, chains, or cables, thereby reducing friction and wear during operation. The return aspect refers to its position in the system where the conveyor belt or chain returns to the starting point after completing its cycle. This allows for continuous operation, reducing downtime and enhancing productivity.

Design Considerations

When designing a Return Idler Bracket, engineers must consider several factors to ensure optimal performance

1. Material Selection The bracket must be made from durable materials that can withstand the rigors of mechanical stress. Common materials include galvanized steel, aluminum, and high-strength plastics, all offering different levels of durability, weight, and corrosion resistance.

2. Load-bearing Capacity The bracket must be designed to support the weight of the return belt while accommodating additional loads that may arise during operation. This requires precise calculations based on the maximum expected load, speed, and any potential dynamic forces.

3. Mounting Options Flexibility in mounting options is vital for the Return Idler Bracket. It should be able to attach securely to various frameworks and structures, allowing for easy installation and maintenance.

4. Alignment and Tension Proper alignment of the idler is crucial to prevent misalignment of the belt or chain, which could lead to increased wear or failure. Additionally, the design must allow for easy adjustments to maintain proper tension in the system.

return idler bracket

5. Environmental Considerations Depending on the application, the Return Idler Bracket may need to endure harsh environments. Factors such as temperature extremes, exposure to chemicals, or moisture can impact material choice and design features.

Practical Applications

The Return Idler Bracket sees widespread use across multiple industries, including

- Manufacturing In manufacturing plants, conveyor systems heavily rely on Return Idler Brackets to efficiently move products through various stages of production.

- Mining and Aggregates In mining operations, these brackets are critical for supporting long conveyor belts that transport heavy materials over considerable distances.

- Agriculture Agricultural machinery often employs Return Idler Brackets for the effective movement of materials, whether it's grain, seeds, or harvested crops.

- Warehouse and Logistics In warehouses, automated conveyor systems utilize Return Idler Brackets to streamline the sorting and distribution of goods, thereby enhancing operational efficiency.

Conclusion

In summary, the Return Idler Bracket is a vital component in many mechanical systems, playing an integral role in the smooth operation of conveyor belts, chains, and other transport mechanisms. With thoughtful design and engineering, these brackets can significantly improve the efficiency and longevity of various machinery, ultimately contributing to productivity and reliability across industries. Understanding their design and functionality is essential for engineers and technicians aiming to optimize system performance and minimize maintenance costs.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025