Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu फरवरी . 19, 2025 05:11

Back to list

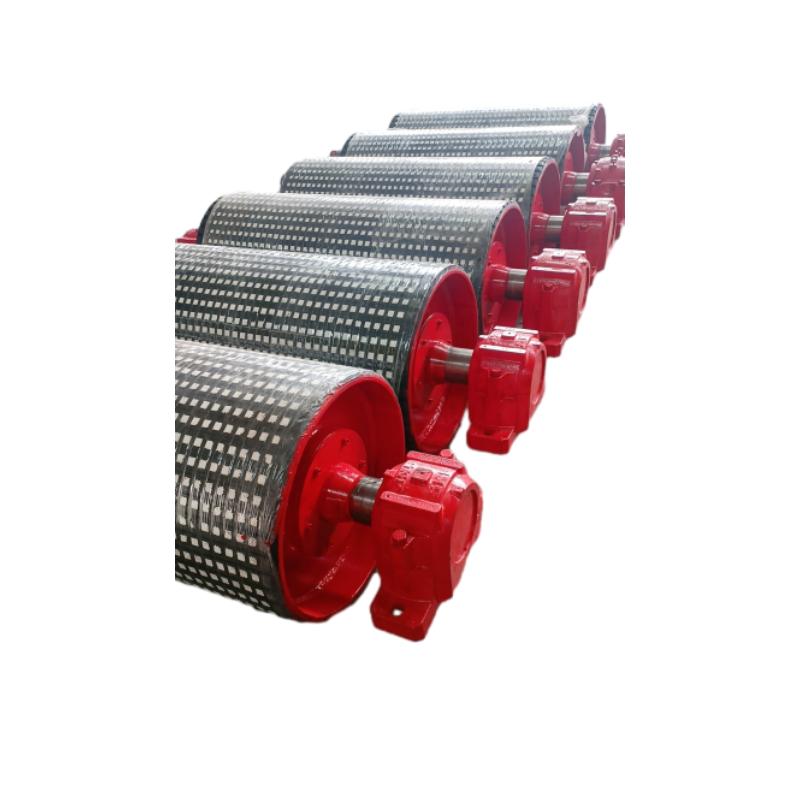

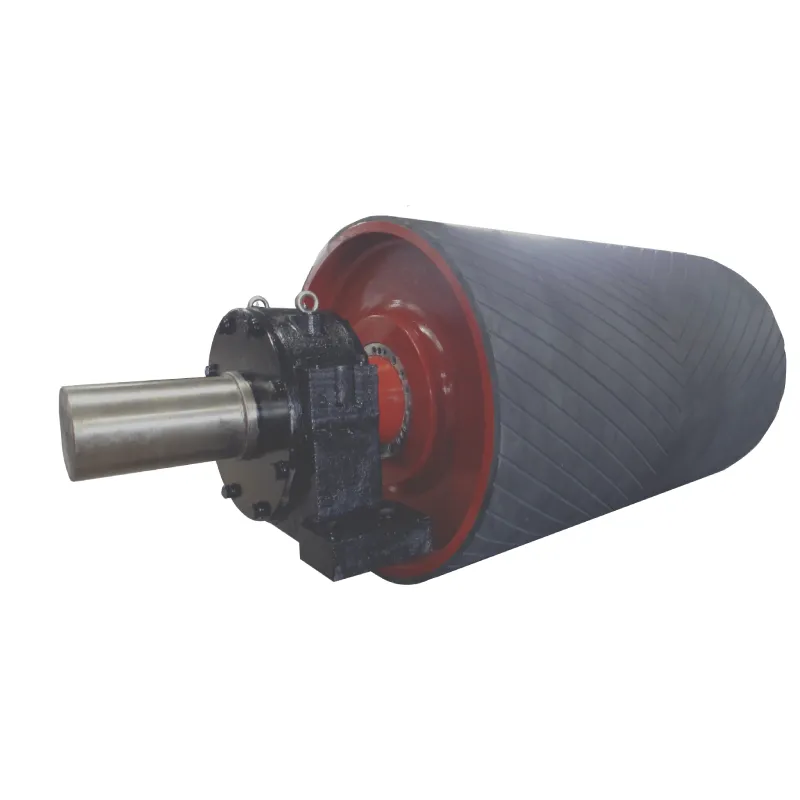

ceramic lagging pulley

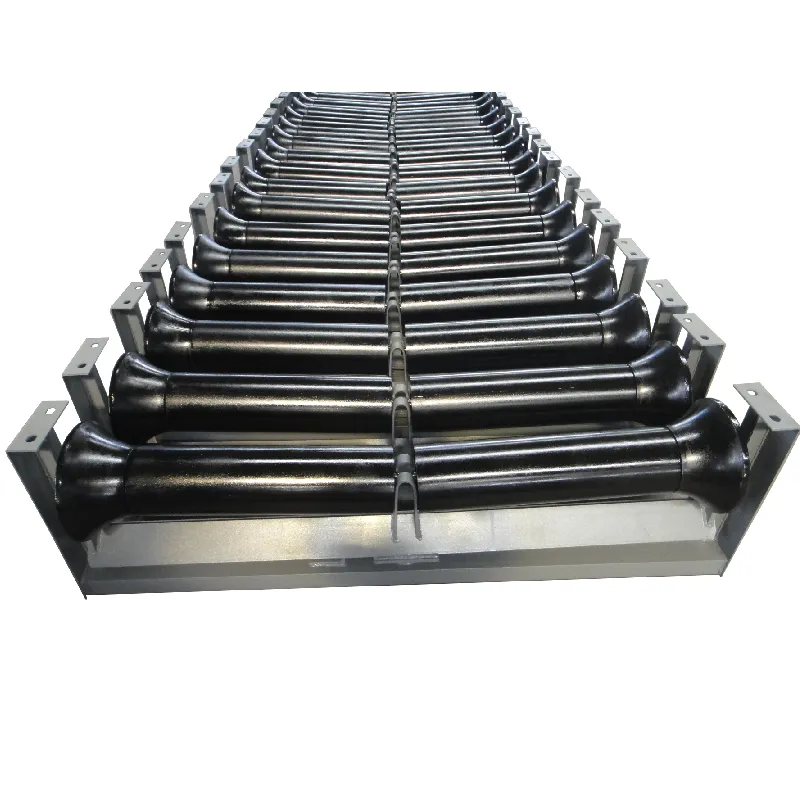

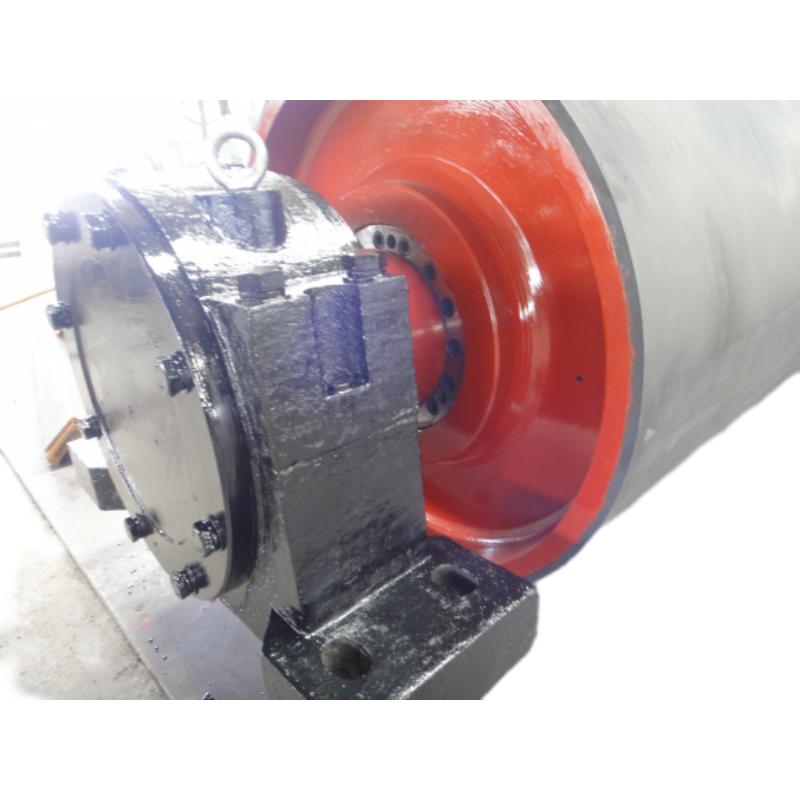

Drum lagging is a critical component in the mechanical handling and conveyor systems industry, offering essential advantages that enhance operational efficiency and equipment longevity. This article delves into the intricacies of drum lagging, emphasizing its impact on performance and maintenance, backed by expert experiences and authoritative insights.

Polyurethane lagging is distinguished by its chemical resistance and operational adaptability in diverse environments, including extreme temperatures. Industries such as chemical processing often turn to polyurethane lagging to address challenges related to chemical exposure and temperature fluctuations. Feedback from professionals working with polyurethane lagging highlights its minimal maintenance requirements and impressive lifespan, reinforcing its authority in applications requiring robust chemical resistance. The expertise in installing drum lagging is another critical factor influencing its overall effectiveness. Professionals stress the importance of precision in installation to maximize the benefits. Incorrect installation can lead to misalignment and reduced traction, counteracting the very advantages drum lagging offers. Therefore, partnering with experienced technicians and adhering to manufacturer guidelines is crucial in ensuring that the lagging performs optimally. Beyond material choice and installation, proper maintenance of drum lagging is vital for sustained performance. Regular inspections and timely replacement of worn lagging are recommended to prevent unexpected breakdowns. Experts suggest incorporating lagging inspection as part of routine maintenance schedules. This proactive approach not only preserves the efficiency of conveyor systems but also builds trust with stakeholders, showcasing a commitment to operational excellence and reliability. In conclusion, drum lagging serves as a fundamental enhancement to conveyor systems, addressing key challenges such as belt slippage and wear. The choice of material should align with the specific operational demands, guided by expert recommendations. Moreover, the critical role of proper installation and maintenance cannot be overstated, collectively ensuring that drum lagging contributes to improved performance, reduced downtime, and extended equipment life. By leveraging authoritative insights and proven practices, industries can harness the full potential of drum lagging, fostering a trustworthy and efficient operational environment.

Polyurethane lagging is distinguished by its chemical resistance and operational adaptability in diverse environments, including extreme temperatures. Industries such as chemical processing often turn to polyurethane lagging to address challenges related to chemical exposure and temperature fluctuations. Feedback from professionals working with polyurethane lagging highlights its minimal maintenance requirements and impressive lifespan, reinforcing its authority in applications requiring robust chemical resistance. The expertise in installing drum lagging is another critical factor influencing its overall effectiveness. Professionals stress the importance of precision in installation to maximize the benefits. Incorrect installation can lead to misalignment and reduced traction, counteracting the very advantages drum lagging offers. Therefore, partnering with experienced technicians and adhering to manufacturer guidelines is crucial in ensuring that the lagging performs optimally. Beyond material choice and installation, proper maintenance of drum lagging is vital for sustained performance. Regular inspections and timely replacement of worn lagging are recommended to prevent unexpected breakdowns. Experts suggest incorporating lagging inspection as part of routine maintenance schedules. This proactive approach not only preserves the efficiency of conveyor systems but also builds trust with stakeholders, showcasing a commitment to operational excellence and reliability. In conclusion, drum lagging serves as a fundamental enhancement to conveyor systems, addressing key challenges such as belt slippage and wear. The choice of material should align with the specific operational demands, guided by expert recommendations. Moreover, the critical role of proper installation and maintenance cannot be overstated, collectively ensuring that drum lagging contributes to improved performance, reduced downtime, and extended equipment life. By leveraging authoritative insights and proven practices, industries can harness the full potential of drum lagging, fostering a trustworthy and efficient operational environment.

Next:

Latest news

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025

OUR PRODUCTS