Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

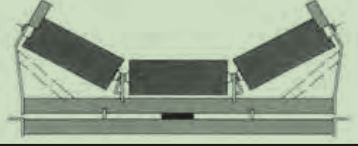

Zulu roller conveyor components

Roller Conveyor Components An Integral Part of Modern Material Handling Systems

In the world of material handling and logistics, efficiency is paramount. One of the key technologies that has reshaped how goods are transported within various industries is the roller conveyor system. This system is made up of various components that work together to facilitate the smooth and effective transport of materials. Understanding these components is essential for anyone looking to optimize their logistics operations.

1. Roller Conveyor Basics

At its core, a roller conveyor is a type of material handling equipment that uses rollers mounted on frames to transport items from one location to another. These conveyors are widely used in manufacturing, distribution centers, and warehouses due to their ability to carry heavy or bulky items. They can be powered or non-powered, with powered roller conveyors commonly utilizing electric motors to drive the rollers.

2. Key Components of Roller Conveyors

Several essential components make up a roller conveyor system, each contributing to its efficiency and effectiveness. Below are some of the key components

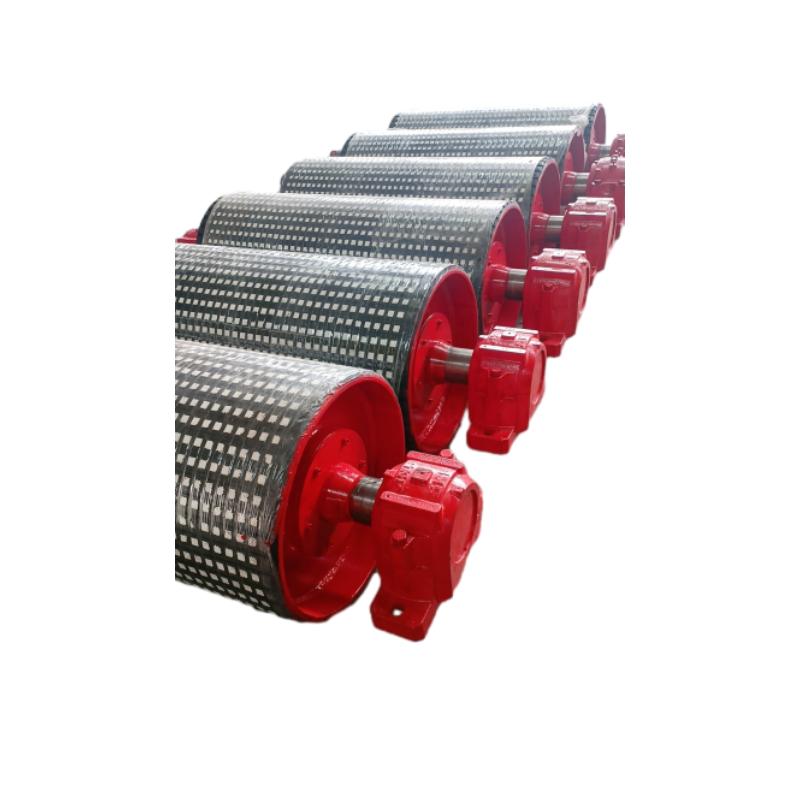

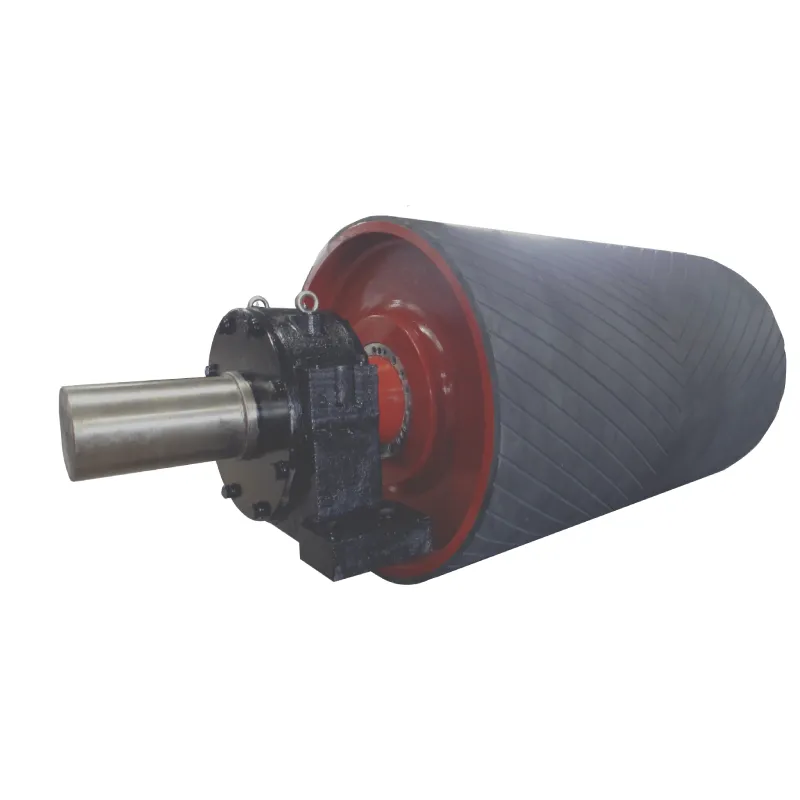

- Rollers The most critical component, rollers are cylindrical elements that allow goods to move along the conveyor. They can be made from materials like steel, plastic, or aluminum, depending on the application's requirements. The diameter and spacing of the rollers can vary based on the load capacity and the type of materials being transported.

- Frames The framework supports the rollers and generally comes in two designs straight or curved. Frames can be made from different materials, including steel or aluminum, ensuring they can support the weight of the rollers and the load being transported.

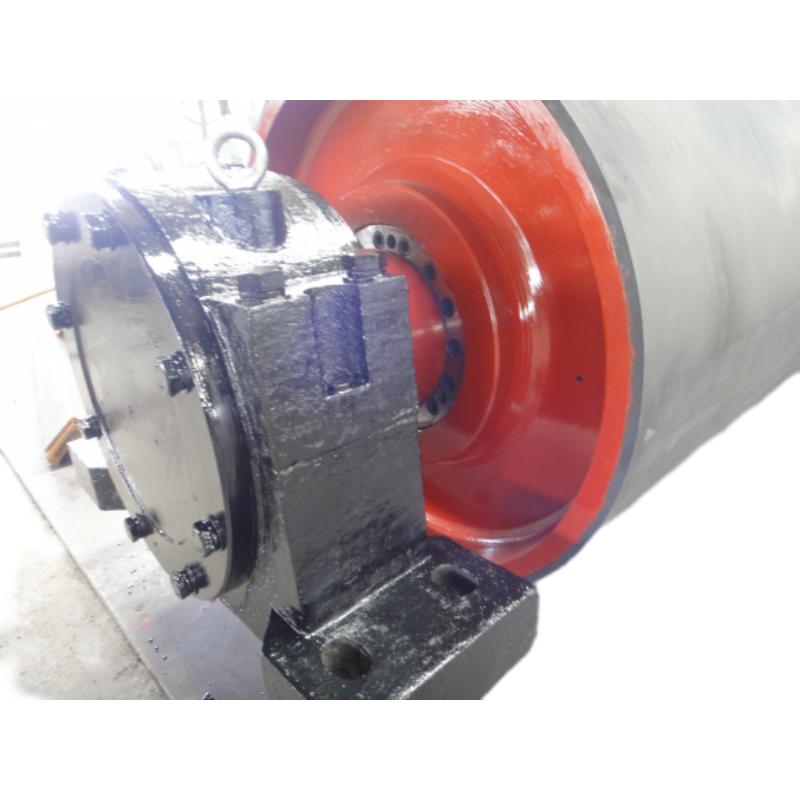

- Drive Mechanism In powered roller conveyors, a drive mechanism, such as a motor or belt, propels the rollers. This mechanism is crucial for maintaining a consistent speed and ensuring that goods move smoothly along the conveyor.

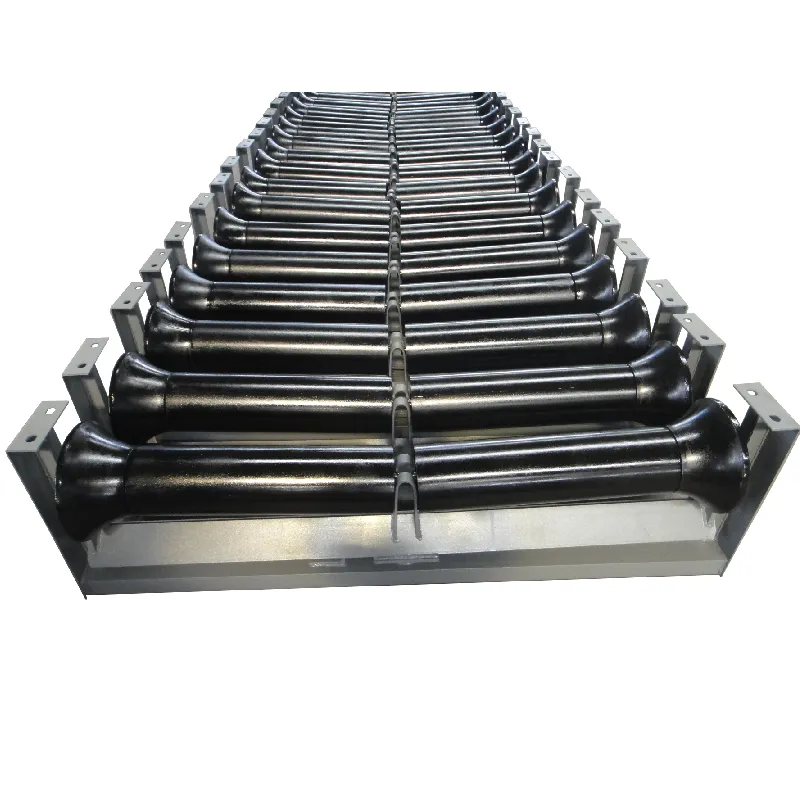

- Idler Rollers These are non-powered rollers that assist in the movement of items on the conveyor. They help create a smooth transition and are often used in sections where powered rollers are not practical.

- Conveyor Belts In some roller conveyor systems, belts may be used in conjunction with rollers to improve traction and movement, particularly for smaller or irregularly shaped items

.roller conveyor components

- Supports and Legs These components provide stability and elevation to the conveyor system. Proper support is essential to ensure that the conveyor can handle heavy loads without sagging or becoming unbalanced.

- Controls Automated systems often feature control panels that allow operators to manage speed, direction, and other parameters of the conveyor system. Advanced controls might include sensors for detecting the presence of items, ensuring efficient and safe operation.

3. Benefits of Roller Conveyors

Roller conveyors offer numerous advantages, which is why they are a popular choice in many industries. Firstly, they can handle a variety of load sizes, from small packages to heavy pallets, making them versatile. Additionally, roller conveyors reduce manual labor by automating the transport of materials, improving efficiency and safety within the workplace.

These systems also promote better organization within warehouses and manufacturing plants, allowing for smoother workflow and easier inventory management. The ability to customize configurations, including straight and curved setups, ensures that a roller conveyor can fit the unique layout of any facility.

4. Maintenance and Considerations

Maintaining a roller conveyor system is vital to ensure its longevity and effective performance. Regular inspections of rollers, frames, and drive mechanisms can prevent costly breakdowns. Lubrication of moving parts and monitoring for wear and tear will keep the conveyor running smoothly.

When selecting roller conveyor components, it’s essential to consider the specific needs of your operation load capacity, speed requirements, and the types of materials being handled. Consulting with conveyor system experts can assist organizations in making informed decisions that enhance their material handling processes.

Conclusion

Roller conveyor components are the backbone of a wide array of material handling applications. From the simple roller to complex control systems, every piece plays a vital role in the efficient movement of goods. By understanding these components, businesses can better appreciate the significance of roller conveyors in optimizing their logistics and supply chain operations, ultimately leading to increased productivity and cost savings.

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025