Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Gearr . 15, 2025 12:31

Back to list

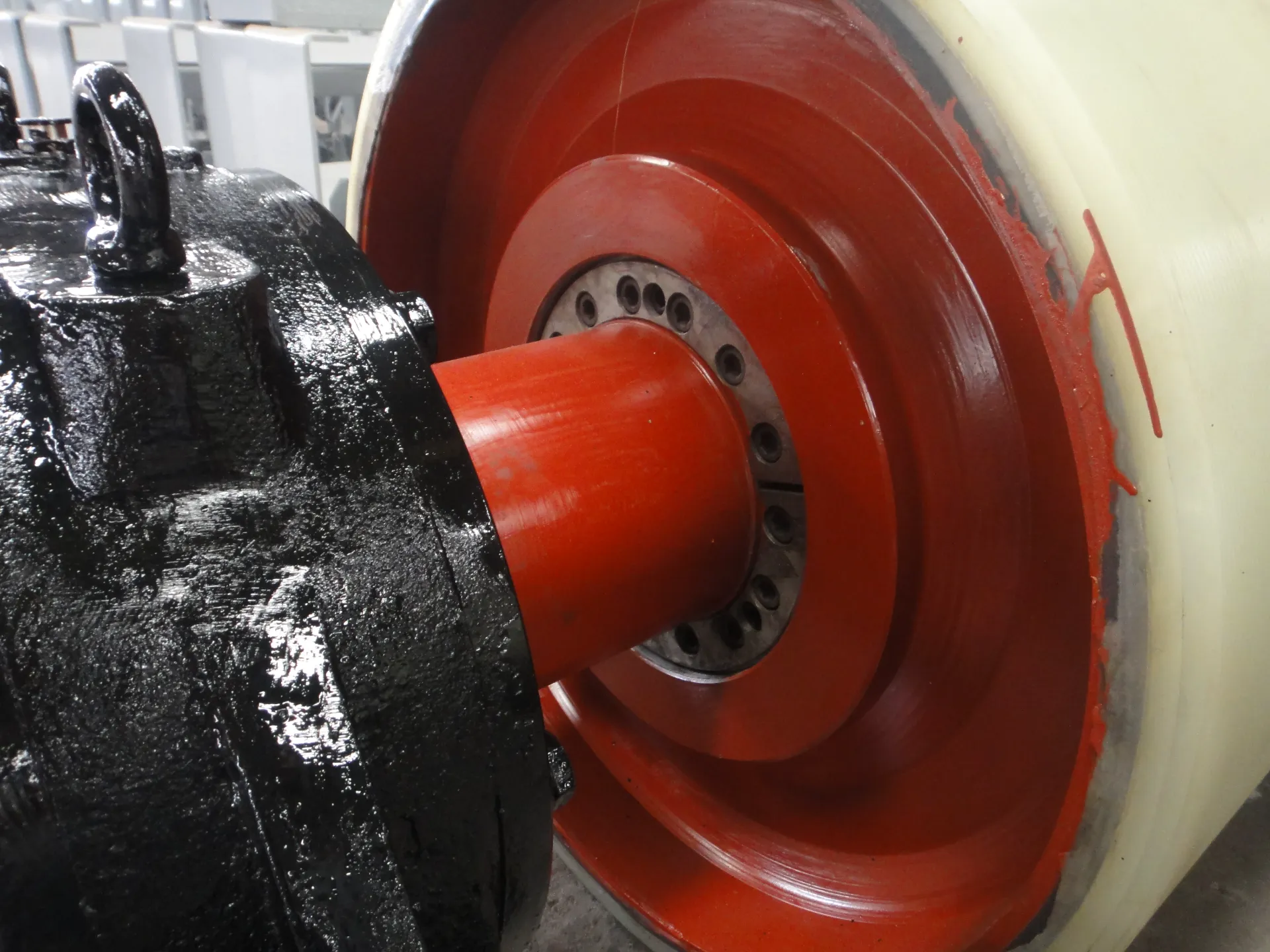

conveyor pulley components

Conveyor systems have become an integral component of the manufacturing and distribution industry, offering efficiency and reliability in transporting materials and products. Understanding the components of a conveyor system is crucial for enhancing operational productivity and minimizing costs. This article delves into the key components that constitute a conveyor system, drawing from industry insights and expertise to offer a comprehensive guide aimed at professionals seeking to optimize their manufacturing processes.

The motors and drives are the powerhouse of the conveyor system, converting electrical energy into mechanical energy required to move the belt and rollers. Selecting the right motor is critical for optimizing energy consumption and achieving the desired throughput. Variable frequency drives (VFDs) are commonly used to regulate motor speed, offering flexibility and better control over the conveyor system. This innovation ensures energy is used efficiently, aligning with current industry trends focused on sustainability and cost reduction. Supporting all component functions, the conveyor system’s structural framework must exhibit robust design and resilience. Made from materials like stainless steel, aluminum, or carbon steel, the framework provides the necessary stability and support for all other components. The design must accommodate the weight of goods and withstand environmental factors, such as humidity or temperature variations that might impact overall system integrity. Customization of the framework design is often necessary to match specific operational requirements, such as space constraints or industry-specific regulations. A conveyor system's efficiency doesn't solely rely on its physical components. Effective control systems, often integrating programmable logic controllers (PLCs), are indispensable for synchronizing operations across various components. These control systems enable the automation of conveyor processes, allowing for predefined sequences and responses to input signals, thus enhancing precision and reducing human error. For a company aiming to streamline operations through conveyor systems, understanding these components is paramount. Careful planning and selection of each component based on specific operational needs can significantly impact productivity and profitability. Implementing regular maintenance and up-to-date technologies fosters trust and reliability, positioning a company as an industry leader committed to quality and efficiency. By leveraging expertise and embracing modern innovations, an organization can enhance its conveyor system to meet evolving demands and maintain a competitive edge.

The motors and drives are the powerhouse of the conveyor system, converting electrical energy into mechanical energy required to move the belt and rollers. Selecting the right motor is critical for optimizing energy consumption and achieving the desired throughput. Variable frequency drives (VFDs) are commonly used to regulate motor speed, offering flexibility and better control over the conveyor system. This innovation ensures energy is used efficiently, aligning with current industry trends focused on sustainability and cost reduction. Supporting all component functions, the conveyor system’s structural framework must exhibit robust design and resilience. Made from materials like stainless steel, aluminum, or carbon steel, the framework provides the necessary stability and support for all other components. The design must accommodate the weight of goods and withstand environmental factors, such as humidity or temperature variations that might impact overall system integrity. Customization of the framework design is often necessary to match specific operational requirements, such as space constraints or industry-specific regulations. A conveyor system's efficiency doesn't solely rely on its physical components. Effective control systems, often integrating programmable logic controllers (PLCs), are indispensable for synchronizing operations across various components. These control systems enable the automation of conveyor processes, allowing for predefined sequences and responses to input signals, thus enhancing precision and reducing human error. For a company aiming to streamline operations through conveyor systems, understanding these components is paramount. Careful planning and selection of each component based on specific operational needs can significantly impact productivity and profitability. Implementing regular maintenance and up-to-date technologies fosters trust and reliability, positioning a company as an industry leader committed to quality and efficiency. By leveraging expertise and embracing modern innovations, an organization can enhance its conveyor system to meet evolving demands and maintain a competitive edge.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS