Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 14, 2025 09:57

Back to list

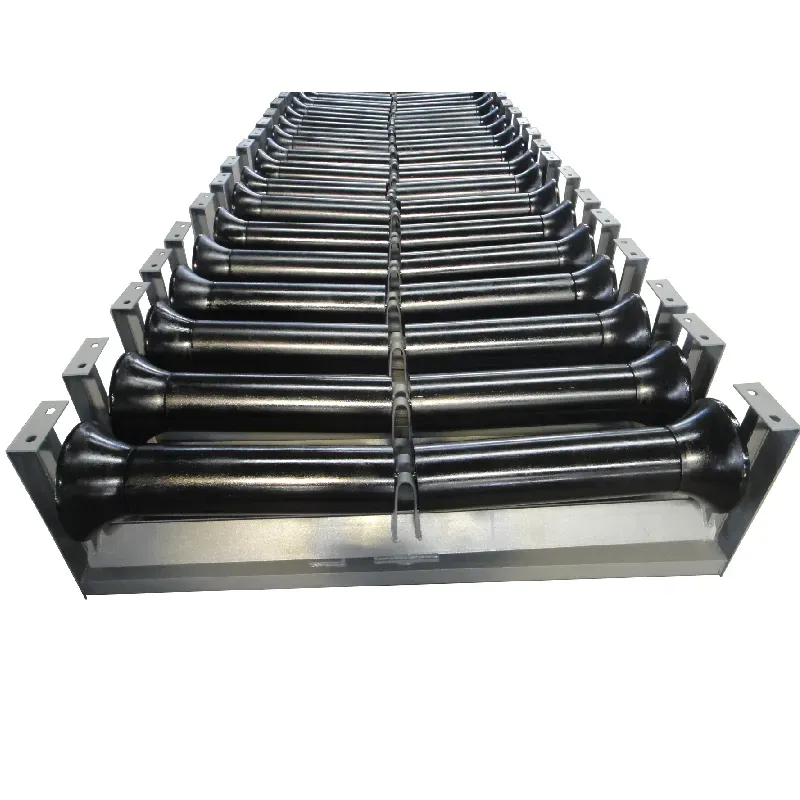

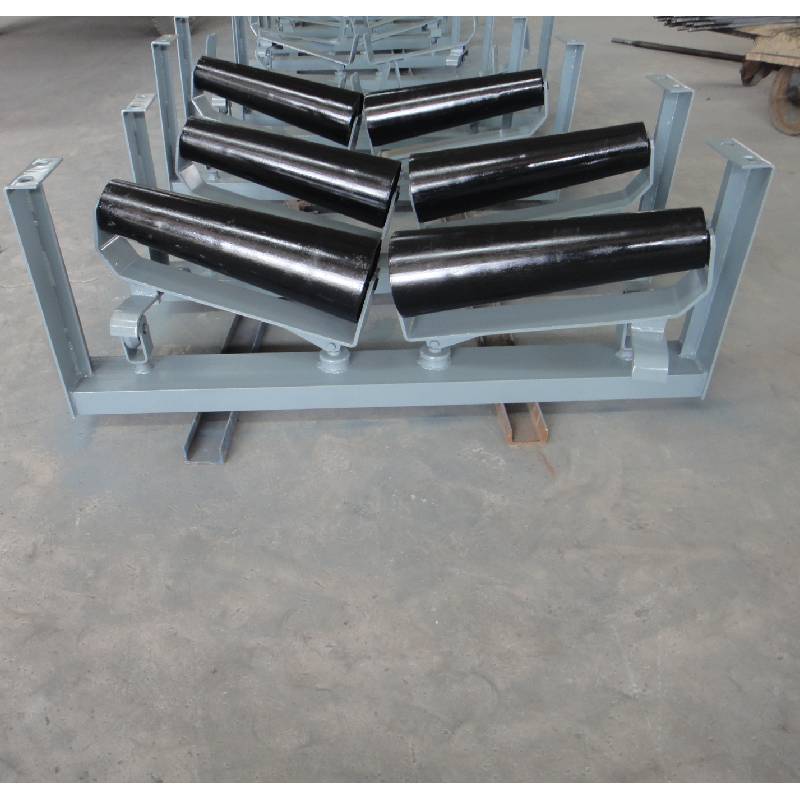

return rollers for conveyors

Conveyor systems play a crucial role in modern industries by enhancing efficiency and productivity. At the heart of these systems are return rollers, often overlooked but vital components ensuring smooth operations. For anyone responsible for maintaining conveyor systems or seeking to maximize their performance, understanding the role and benefits of return rollers is essential.

Expert installation and regular maintenance are crucial for the effective function of return rollers. Misalignment or improper installation can lead to premature roller failure, belt damage, and increased operational costs. Partnering with experienced professionals who specialize in conveyor systems can optimize installation and maintenance processes. They offer valuable insights and expertise that ensure the return rollers function correctly, ultimately safeguarding your conveyor system's longevity. Furthermore, continuous monitoring and timely replacements are key strategies in maintaining efficient return roller performance. Implementing a predictive maintenance schedule can help identify potential failures before they occur, minimizing unexpected breakdowns. Using advanced technologies like vibration analysis and thermal imaging, maintenance teams can pinpoint issues at an early stage and apply necessary interventions efficiently. Trust in the industry experts when choosing your return rollers to benefit from the latest innovations and technological advancements. By doing so, companies can maintain high standards of operational efficiency, safety, and reliability. For businesses eager to optimize their conveyance systems, focusing on return rollers is a practical and impactful first step. The investment in quality return rollers and expert maintenance can yield substantial returns in operational uptime and cost savings. Understanding and applying this knowledge ensures a competitive edge in industries where speed and efficiency are paramount.

Expert installation and regular maintenance are crucial for the effective function of return rollers. Misalignment or improper installation can lead to premature roller failure, belt damage, and increased operational costs. Partnering with experienced professionals who specialize in conveyor systems can optimize installation and maintenance processes. They offer valuable insights and expertise that ensure the return rollers function correctly, ultimately safeguarding your conveyor system's longevity. Furthermore, continuous monitoring and timely replacements are key strategies in maintaining efficient return roller performance. Implementing a predictive maintenance schedule can help identify potential failures before they occur, minimizing unexpected breakdowns. Using advanced technologies like vibration analysis and thermal imaging, maintenance teams can pinpoint issues at an early stage and apply necessary interventions efficiently. Trust in the industry experts when choosing your return rollers to benefit from the latest innovations and technological advancements. By doing so, companies can maintain high standards of operational efficiency, safety, and reliability. For businesses eager to optimize their conveyance systems, focusing on return rollers is a practical and impactful first step. The investment in quality return rollers and expert maintenance can yield substantial returns in operational uptime and cost savings. Understanding and applying this knowledge ensures a competitive edge in industries where speed and efficiency are paramount.

Next:

Latest news

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025

OUR PRODUCTS