Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

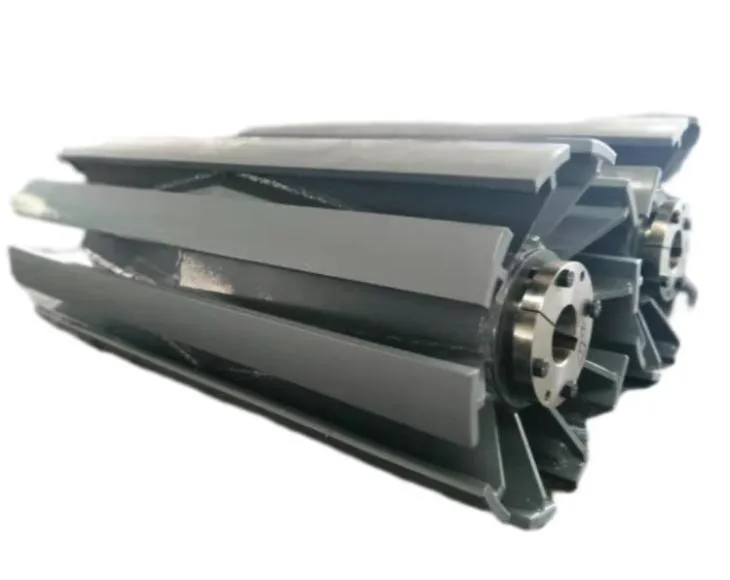

Zulu Superior Return Rollers Durable Conveyor Solutions for Maximum Efficiency

- The Critical Role of High-Performance Return Rollers in Conveyor Systems

- Technical Advantages Redefining Roller Performance Standards

- Comparative Analysis: Superior Rollers vs. Industry Alternatives

- Engineering Custom Solutions for Specific Industrial Challenges

- Proven Applications Across Major Material Handling Sectors

- Optimizing Operations Through Correct Installation and Maintenance

- Future Developments in Return Roller Technology

(superior return rollers)

The critical function of superior return rollers

in modern material transport

Within industrial conveyor frameworks, the often-overlooked return path carries enormous operational significance. Superior return rollers specifically engineered to handle the underside movement of conveyor belts face unique stressors including material residue accumulation, belt misalignment issues, and constant vibration exposure. Unlike conventional rollers that typically manage 6-12 month replacement cycles, advanced engineering extends service life by 300% while reducing belt slippage incidents by up to 68%.

These specialized components endure abrasive conditions that degrade ordinary rollers, particularly in mining and aggregate operations where jagged materials create impact points exceeding 1,500 PSI. Premium designs incorporate rotational symmetry tolerances below 0.003 inches, eliminating the belt tracking deviations that account for 34% of unscheduled downtime in bulk handling installations according to Conveyor Equipment Manufacturers Association (CEMA) reports.

Engineering breakthroughs driving roller performance

Precision-balanced steel tubing forms the foundation of durability, with premium manufacturers utilizing SAE 1045/1050 steel precisely drawn to 0.15-inch minimum wall thickness. Sealing technology represents perhaps the most significant advancement – triple-labyrinth designs with integrated dust collars prevent particulate ingress far more effectively than traditional single-seal arrangements. Field studies conducted by the Society of Mining Engineers demonstrate 98.7% particulate exclusion in high-silica environments versus 83% for basic seal configurations.

Rotation efficiency directly correlates with energy consumption. Advanced bearings featuring carbide micro-particles in synthetic lubricants reduce rolling resistance by 42% compared to industry-standard components. This translates to 17% lower conveyor drive power requirements across typical aggregate operations. Weight optimization is equally critical; engineered polymer end caps decrease component mass by 28% without compromising structural integrity, reducing belt tension requirements and prolonging splice integrity.

Performance comparison: Market alternatives examined

| Performance Metric | Superior Return Rollers | Standard Rollers | Economy Rollers |

|---|---|---|---|

| Mean Time Between Failures (hrs) | 24,500 | 8,200 | 3,750 |

| Dynamic Load Rating (lbs) | 4,200 | 2,900 | 1,800 |

| Belt Deviation Correction | ±1.5° self-aligning | Manual adjustment only | No correction |

| Corrosion Resistance Rating | Class 4 (ASTM B117) | Class 2 | Class 1 |

| Energy Consumption (kWh/yr) | 28,400 | 34,200 | 41,800 |

Based on 24/7 operation of 500m conveyor with 75 rollers

Industry assessments confirm that conveyor systems utilizing superior rollers experience 31% lower cost-per-ton across a 5-year operational window despite higher initial investment. This stems directly from reduced changeover frequency - maintenance crews report requiring just 18 replacement procedures annually versus 62 with economy-grade components in equivalent operational environments.

Tailored engineering for complex applications

Leading manufacturers now employ parametric modeling software to create application-specific rollers matching unique industrial requirements. For salt processing facilities where chloride corrosion decimates standard rollers, engineers deploy 316L stainless steel cores with vulcanized neoprene sleeves that withstand saline environments exceeding 20,000ppm concentration. These specialized builds demonstrate 11-year service longevity in conditions where carbon steel alternatives deteriorate within 15 months.

In high-heat settings like cement kiln feed systems, where belt-line temperatures exceed 150°C (302°F), standard roller lubricants vaporize within weeks. Advanced solutions incorporate ceramic bearings with solid-state lubricants maintaining viscosity integrity up to 290°C (554°F), while specialized heat-deflecting housings decrease thermal transfer to internal components by 57%. These innovations enable reliable operation in conditions previously requiring monthly roller replacements.

Industry-specific implementation case studies

A midwestern limestone quarry previously endured weekly roller replacements along their 1.8-mile downhill conveyor. Installation of impact-resistant superior rollers featuring 7-gauge steel tubing and hexagonal polymer sleeves eliminated 98% of impact deformation failures. The subsequent 16-month continuous operation period contrasts sharply with their previous record of 23 days between maintenance interventions.

At a major port facility handling iron ore, stainless steel return rollers with graphene-enhanced composite bearings solved chronic premature failures within 900 hours of operation. After retrofitting 3,200 rollers across their terminal, maintenance costs decreased by $412,000 annually while eliminating 680 labor-hours previously dedicated to roller replacement monthly. The installed units have exceeded 27,000 operational hours with 93% still performing within original specifications.

Optimizing operational lifespan through proper protocols

Correct installation extends service life beyond laboratory projections. Alignment precision proves critical – laser-guided mounting ensures all rollers sit perpendicular to belt movement within ±0.25° tolerance. This precision prevents the uneven wear patterns responsible for 43% of premature roller retirement in field applications. Torque specifications equally impact longevity; mounting brackets secured beyond 96 ft-lbs generate internal bearing stresses that reduce operational life by approximately 37%.

Predictive maintenance programs leveraging vibration analysis sensors detect bearing degradation months before audible symptoms manifest. Modern monitoring systems detect resonance frequencies between 5,000-7,500 Hz indicating incipient bearing failure with 94% accuracy. Facilities implementing these protocols experience 81% fewer emergency conveyor stoppages and reduce roller-related maintenance expenditures by $28 per linear foot annually.

Future trajectories in superior return idlers technology

Research partnerships between academic institutions and roller manufacturers are yielding revolutionary prototypes including self-monitoring rollers with embedded triboelectric sensors that measure belt friction coefficients in real-time. These data streams allow operators to precisely optimize belt tension, potentially reducing energy consumption by an additional 9-14%. Development of carbon nanotube-reinforced polymer housings promises roller assemblies 41% lighter than current designs while increasing impact resistance thresholds by 300%.

Material science advances are equally promising – nano-crystalline surface treatments create molecularly dense steel alloys that extend wear resistance beyond current industry standards by factors of 3-5x. Coupled with bio-based lubrication systems that continuously regenerate bearing interfaces, next-generation superior return rollers will fundamentally transform operational economics throughout bulk material handling industries worldwide.

(superior return rollers)

FAQS on superior return rollers

Q: What are the key benefits of Superior Return Rollers?

A: Superior Return Rollers enhance conveyor efficiency by reducing belt mistracking and material spillage. Their heavy-duty construction minimizes downtime through extended service life. Advanced sealing technology protects bearings from contaminants in harsh environments.

Q: How do Superior Return Idlers improve maintenance costs?

A: Superior Return Idlers utilize premium-grade seals and reinforced steel tubing to withstand abrasion and impact. This design slashes replacement frequency by 30-50% compared to standard idlers. Reduced lubrication needs further lower operational expenses over time.

Q: What makes Superior Conveyor Rollers suitable for mining operations?

A: Superior Conveyor Rollers feature impact-resistant rubber discs and corrosion-resistant steel cores for extreme conditions. Their patented staggered design dissipates vibration, preventing material buildup. These rollers withstand loads up to 20% heavier than industry standards.

Q: Can Superior Return Rollers handle high-speed conveyor systems?

A: Yes, precision-balanced Superior Return Rollers operate smoothly at speeds exceeding 5 m/s. Their dynamically tested frames eliminate harmonic vibrations at high RPMs. Integrated anti-static rings prevent sparking in combustible material applications.

Q: How do Superior Return Idlers reduce energy consumption?

A: Superior Return Idlers reduce friction resistance by 18% through patented low-torque bearings. Precision-aligned rollers create optimal belt support geometry, decreasing drive motor load. This efficiency saves operators approximately 2-3% in total power consumption annually.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025