Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  Inglise

Inglise  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu High-Performance Belt Conveyor Pulleys for Reliable Material Handling

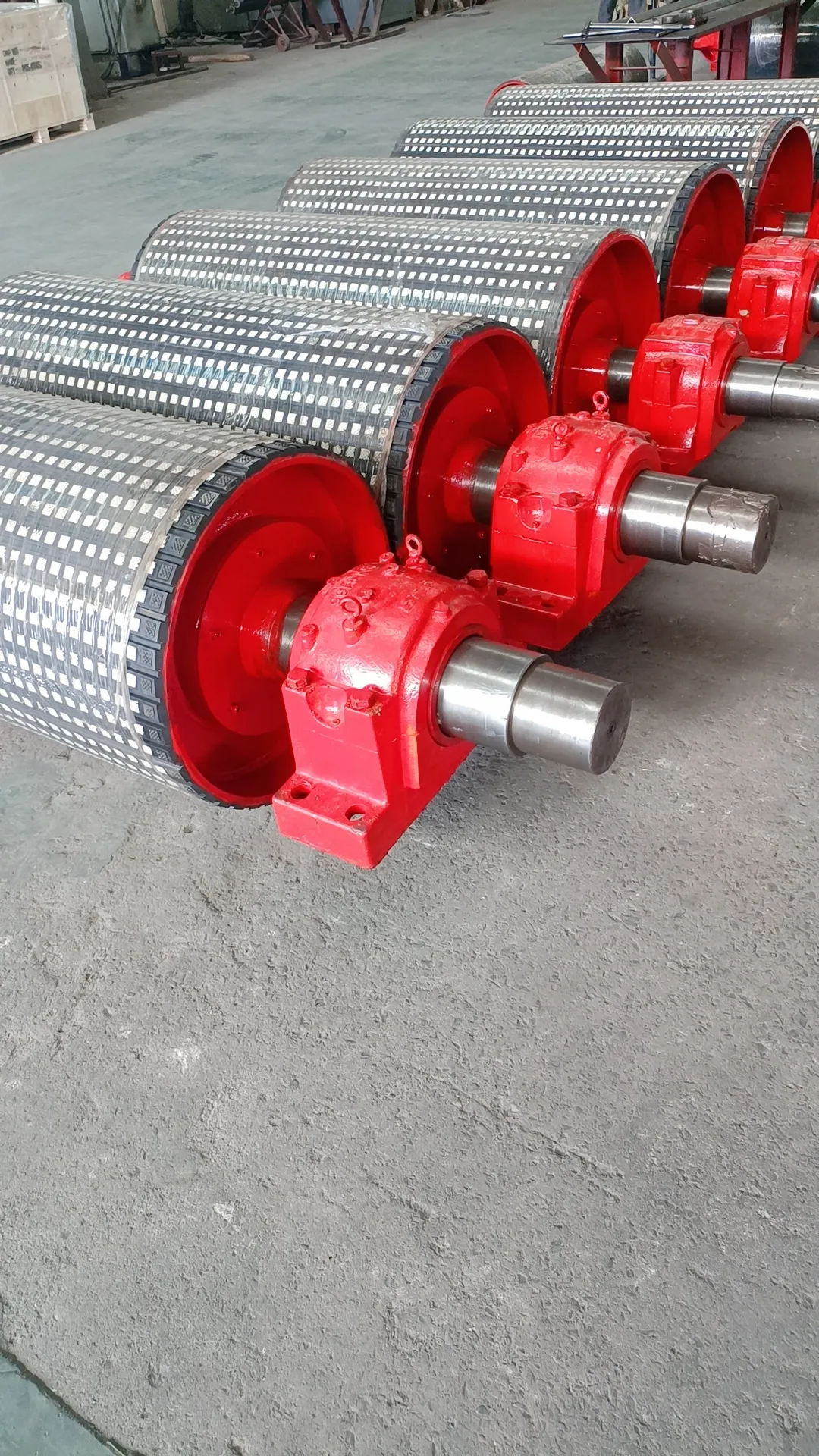

In any conveyor system, the pulley is a critical component that drives and guides the conveyor belt, ensuring efficient and stable material transport. From the belt conveyor pulley to specialized components like the ceramic lagging pulley, these parts must meet stringent quality and durability standards to withstand demanding industrial environments. Yanshan Aohua Machinery Equipment Manufacture Limited Company is a leading name among conveyor pulley manufacturers, offering a wide range of high-quality conveyor pulleys and conveyor drums designed for optimal performance and long service life. Leveraging advanced technology and skilled engineering, Aohua delivers solutions that support industries worldwide in achieving smooth, uninterrupted conveyor operations.

belt conveyor pulley: Driving Smooth and Efficient Conveyor Operations

The belt conveyor pulley is essential for the transmission of power to the conveyor belt, enabling it to move materials continuously and reliably. Designed to provide proper traction and minimize slippage, these pulleys are precision-engineered using premium materials to resist wear and corrosion. Yanshan Aohua’s belt conveyor pulleys undergo strict quality control, including dynamic balancing and machining accuracy tests, to ensure they perform flawlessly under heavy loads and harsh conditions. Their robust construction supports various conveyor types and sizes, helping industries maintain high productivity levels with reduced downtime.

conveyor pulley and ceramic lagging pulley: Enhancing Traction and Durability

While standard conveyor pulleys provide the fundamental drive and guidance functions, adding a ceramic lagging pulley enhances belt grip and protects the pulley surface from abrasion. The ceramic lagging coating offers superior resistance to wear and slippage, extending the pulley’s service life and improving overall conveyor reliability. Yanshan Aohua specializes in manufacturing ceramic lagging pulleys tailored to client specifications, using high-quality ceramic materials bonded securely to the pulley shell. This innovation is particularly valuable in heavy-duty and high-friction applications such as mining and bulk material handling, where maintaining belt traction is crucial for safety and efficiency.

conveyor pulley manufacturers: Delivering Customized Solutions with Quality Assurance

Selecting the right conveyor pulley manufacturers is critical to securing components that match specific operational requirements. Yanshan Aohua stands out among conveyor pulley manufacturers due to its comprehensive manufacturing capabilities, experienced engineering team, and commitment to customization. The company produces a variety of pulley types, including drive pulleys, tail pulleys, and bend pulleys, all designed to fit diverse conveyor setups. With advanced machinery and rigorous testing, Aohua ensures every pulley meets international quality standards, providing customers with reliable, long-lasting components. Their strategic location near major ports also facilitates timely delivery for global clients.

conveyor drum: Core Component for Efficient Power Transmission and Belt Support

The conveyor drum is a key element in conveyor systems, combining the functions of pulley and belt support. It transmits power to the belt while bearing the mechanical stresses involved in material handling. Yanshan Aohua’s conveyor drums are manufactured using high-strength steel and precision machining to ensure balance and durability. The company offers customizable features such as different lagging types, bearing assemblies, and shaft configurations to meet unique operational needs. By focusing on quality from material selection to final assembly, Aohua delivers conveyor drums that contribute to smooth, reliable conveyor performance and minimize maintenance requirements.

belt conveyor pulley FAQs

What is the role of a belt conveyor pulley in a conveyor system?

The belt conveyor pulley drives and guides the conveyor belt, transmitting power from the motor to move materials continuously. It provides necessary traction to prevent belt slippage and maintains belt alignment, ensuring smooth and efficient conveyor operation.

How does a ceramic lagging pulley improve conveyor performance?

A ceramic lagging pulley enhances belt traction by providing a high-friction, wear-resistant surface on the pulley. This reduces belt slippage, extends pulley service life, and improves safety and efficiency, especially in heavy-duty applications involving abrasive materials.

What factors should be considered when choosing conveyor pulley manufacturers?

When selecting conveyor pulley manufacturers, consider their manufacturing capabilities, quality control processes, customization options, and delivery reliability. A reputable manufacturer like Yanshan Aohua offers advanced production technology, experienced engineering, and adherence to international standards, ensuring high-quality and tailored products.

What distinguishes conveyor drums from standard pulleys?

Conveyor drums combine pulley functions with structural support for the belt, handling power transmission and bearing mechanical loads. They are built to higher strength and balance standards compared to simple pulleys, often customized with lagging and bearing options to suit specific conveyor demands.

How do conveyor drums contribute to reducing maintenance in conveyor systems?

By using high-quality materials and precision engineering, conveyor drums provide stable and durable support to the conveyor belt. Features such as quality lagging and sealed bearings minimize wear, prevent slippage, and reduce vibration, which lowers the frequency of maintenance and extends system uptime.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysUudisedJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsUudisedJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesUudisedJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysUudisedJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerUudisedJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersUudisedJul.22,2025