Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Peb . 14, 2025 09:34

Back to list

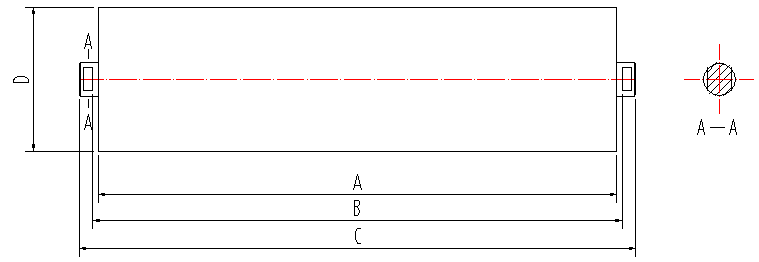

spring loaded guide rollers

Exploring the Dynamics and Utility of Spring Loaded Guide Rollers

Moreover, their design must cater to the nuanced dynamics of industrial operations. The internal spring mechanism varies, ranging from compression springs, which cater to linear forces, to torsion springs for rotational applications. Such diversity in design caters to the specific demands of different industries, ensuring each roller is fit-for-purpose. The authoritativeness of spring loaded guide rollers extends into the operational cost benefits they provide. By facilitating smoother operations and requiring minimal maintenance, these rollers represent an upfront investment that leads to long-term savings. Energy efficiency is another consideration, as reduced friction equates to lesser energy consumption—a crucial factor as industries pivot towards sustainable practices. Trustworthiness in the usage of spring loaded guide rollers is underscored by the testimonies of leading experts and manufacturers who attest to their reliability and make strategic recommendations based on specific industrial needs. For example, companies specializing in high-speed processes may opt for rollers with higher spring tension to cope with rapid operations, whereas those in heavy-duty sectors might prioritize load-bearing capabilities. In conclusion, spring loaded guide rollers are essential components that enhance operational efficiency and material handling across various industries. Their dynamic ability to adapt to material variances, combined with robust engineering and energy efficiency, positions them as indispensable assets within any material handling or processing unit. For industry professionals seeking to leverage these advantages, understanding the specific operational requirements and roller specifications will be key to maximizing productivity and ensuring streamlined industrial operations.

Moreover, their design must cater to the nuanced dynamics of industrial operations. The internal spring mechanism varies, ranging from compression springs, which cater to linear forces, to torsion springs for rotational applications. Such diversity in design caters to the specific demands of different industries, ensuring each roller is fit-for-purpose. The authoritativeness of spring loaded guide rollers extends into the operational cost benefits they provide. By facilitating smoother operations and requiring minimal maintenance, these rollers represent an upfront investment that leads to long-term savings. Energy efficiency is another consideration, as reduced friction equates to lesser energy consumption—a crucial factor as industries pivot towards sustainable practices. Trustworthiness in the usage of spring loaded guide rollers is underscored by the testimonies of leading experts and manufacturers who attest to their reliability and make strategic recommendations based on specific industrial needs. For example, companies specializing in high-speed processes may opt for rollers with higher spring tension to cope with rapid operations, whereas those in heavy-duty sectors might prioritize load-bearing capabilities. In conclusion, spring loaded guide rollers are essential components that enhance operational efficiency and material handling across various industries. Their dynamic ability to adapt to material variances, combined with robust engineering and energy efficiency, positions them as indispensable assets within any material handling or processing unit. For industry professionals seeking to leverage these advantages, understanding the specific operational requirements and roller specifications will be key to maximizing productivity and ensuring streamlined industrial operations.

Next:

Latest news

-

The Unrivaled Performance of Polyurethane Pulleys in Industrial ApplicationsNewsAug.25,2025

-

The Critical Role of Drum Lagging in Conveyor SystemsNewsAug.25,2025

-

Navigating Industrial Efficiency: The Critical Role of Conveyor PulleysNewsAug.25,2025

-

InIntroduction to Advanced Pulley Lagging SolutionsNewsAug.25,2025

-

Industry Trends in Pulley Lagging TechnologyNewsAug.25,2025

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

OUR PRODUCTS