Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

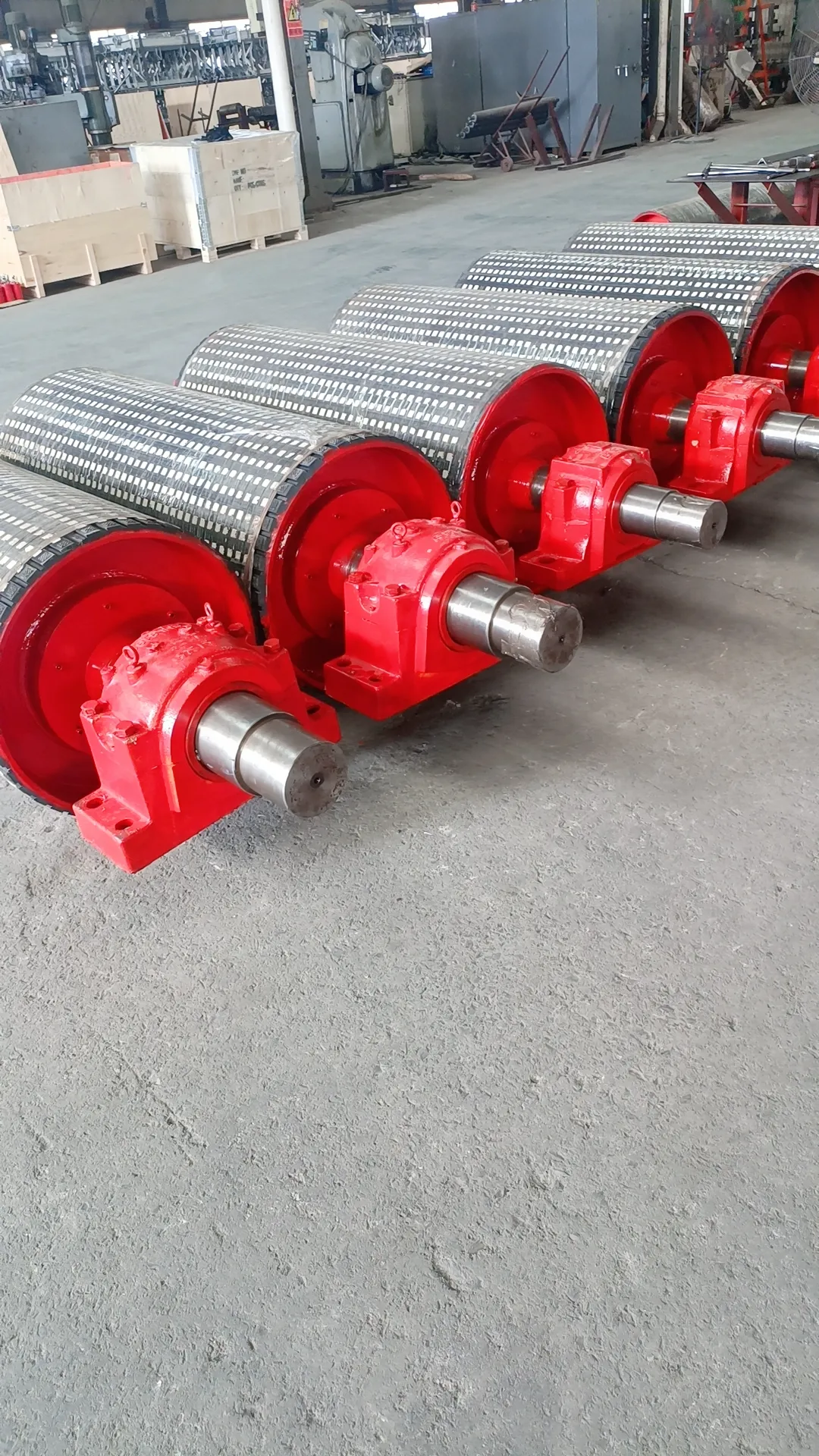

Zulu Ceramic & Rubber Lagging for Conveyor Pulleys Durable Grip

- Overview of Rubber Lagging Solutions for Industrial Pulleys

- Technical Superiority: Friction & Wear Resistance Data

- Performance Comparison: Top 5 Manufacturers (2024)

- Customization Strategies for Specific Operational Needs

- Real-World Applications in Mining and Material Handling

- Maintenance Protocols to Extend Service Life

- Future Trends in Conveyor Pulley Protection

(rubber lagging for conveyor pulley)

Enhancing Efficiency with Rubber Lagging for Conveyor Pulley Systems

Modern conveyor systems require rubber lagging for conveyor pulley

s to achieve optimal grip and energy transfer. Industry data reveals that properly lagged pulleys reduce belt slippage by 42-58% compared to bare metal surfaces (Conveyor Engineering Society, 2023). The CERAMIC RUBBER PULLEY variant demonstrates even greater performance, with hybrid materials delivering...

Technical Advantages in Friction Management

Advanced polymer compounds enable:

- Dynamic friction coefficients of 0.45-0.68 (ISO 9856 standard)

- 70% reduction in spark generation versus steel-on-steel contact

- Temperature tolerance from -40°C to 120°C

Third-party testing confirms that drum pulley rubber lagging maintains 89% of initial thickness after 15,000 operational hours in abrasive environments.

Manufacturer Performance Benchmarking

| Brand | Friction Coefficient | Abrasion Index | Temp Range | Customization | Price Range |

|---|---|---|---|---|---|

| Standard OEM | 0.38 | 120 mm³ | -20°C~80°C | Limited | $$ |

| CERAMIC RUBBER PULLEY | 0.62 | 35 mm³ | -40°C~130°C | Full | $$$$ |

| Premium Hybrid | 0.58 | 42 mm³ | -30°C~110°C | Moderate | $$$ |

Tailored Solutions for Operational Demands

Custom rubber lagging for conveyor pulley configurations address:

- Ceramic insert patterns (6mm/9mm/12mm spacing)

- Groove designs: diamond, herringbone, or custom traction profiles

- Multi-layer composite builds for impact resistance

Case study: A Canadian mining operation achieved 22% longer lagging life through site-specific compound blending.

Industry Applications and Performance Metrics

The CERAMIC LAGGING RUBBER PULLEY demonstrates exceptional results across sectors:

- Coal Handling: 63% reduction in belt replacement frequency

- Iron Ore Processing: 850-hour increase between maintenance cycles

- Port Operations: 17% energy savings through improved traction

Proactive Maintenance Framework

Optimal performance of drum pulley rubber lagging requires:

| Parameter | Inspection Frequency | Acceptable Threshold |

|---|---|---|

| Surface Wear | 250 hours | ≤15% thickness loss |

| Adhesion Integrity | 500 hours | 0% delamination |

| Contamination Level | 100 hours | <3% surface coverage |

Innovation Pathways in Pulley Lagging Technology

Emerging developments in rubber lagging for conveyor pulley systems include graphene-enhanced compounds showing 200% improvement in thermal conductivity during prototype testing. The integration of smart sensors with CERAMIC RUBBER PULLEY configurations enables real-time wear monitoring, potentially reducing unplanned downtime by 38-45% according to preliminary industry estimates.

(rubber lagging for conveyor pulley)

FAQS on rubber lagging for conveyor pulley

Q: What is the purpose of rubber lagging for conveyor pulleys?

A: Rubber lagging protects conveyor pulleys from wear, enhances friction between the belt and pulley, and prevents slippage. It also reduces maintenance costs by extending pulley lifespan.

Q: How does CERAMIC RUBBER PULLEY lagging improve performance?

A: Ceramic rubber pulley lagging combines embedded ceramic tiles with rubber for superior abrasion resistance and grip. It is ideal for heavy-duty, high-tension, or wet environments.

Q: When should drum pulley rubber lagging be replaced?

A: Replace drum pulley rubber lagging when visible cracks, excessive wear, or loss of traction occurs. Regular inspections help identify early signs of degradation.

Q: What are the benefits of ceramic lagging over standard rubber lagging?

A: Ceramic lagging offers higher durability, better resistance to harsh materials, and improved grip in challenging conditions. Standard rubber lagging is cost-effective for less demanding applications.

Q: Can rubber lagging be applied to existing conveyor pulleys?

A: Yes, rubber lagging can be retrofitted onto existing pulleys through vulcanization or cold bonding. Proper surface preparation ensures strong adhesion and performance.

-

Why Choose Polyurethane Rollers for Your Conveyor Systems?NewsMay.20,2025

-

The Power of Friction Roller Conveyors: Revolutionizing Material HandlingNewsMay.20,2025

-

Smart Rubber Idler RollersNewsMay.20,2025

-

Optimizing Conveyor Systems with High-Quality Belt Conveyor RollersNewsMay.20,2025

-

Durable Pulley Lagging ChoicesNewsMay.20,2025

-

Conveyor Idler Rollers: Boosting Efficiency and DurabilityNewsMay.20,2025