Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu فبراير . 07, 2025 01:11

Back to list

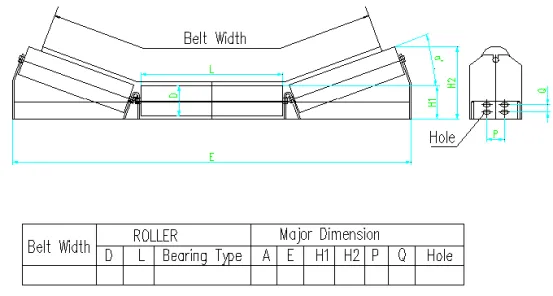

rubber disc return rollers

Rubber disc return rollers are pivotal elements in the conveyor systems, often overlooked yet integral for efficient material handling in various industries. When considering the implementation of these rollers, a comprehensive understanding of their functions, benefits, and operational guidelines can significantly enhance system performance.

In terms of authoritativeness and trustworthiness, many leading brands and manufacturers have demonstrated their commitment to quality through extensive testing and certification processes. Compliance with international standards such as ISO and DIN ensures that these rollers meet the stringent benchmarks required for operational safety and efficiency. Companies that invest in high-quality rubber disc return rollers often experience a return on investment through reduced maintenance costs and enhanced system uptime. Moreover, rubber disc return rollers are also aligned with environmental sustainability goals. Their durable construction reduces the frequency of replacements, thus minimizing waste. Some manufacturers have gone a step further by utilizing recycled rubber in their production processes, contributing to ecological conservation. Practical tips for optimizing the use of rubber disc return rollers include regular inspection and maintenance schedules. Routine checks for wear and any signs of damage can prevent potential operational disruptions. Ensuring that the rollers are correctly aligned and secured can further promote system efficiency and longevity. To sum up, rubber disc return rollers are an essential component in any well-functioning conveyor system. Their specialized design not only enhances belt performance and reliability but also provides cost-effective and environmentally sustainable solutions for various industries. By leveraging expertise in selection, installation, and maintenance, organizations can harness the full potential of these critical assets, establishing a robust foundation for streamlined and productive operations.

In terms of authoritativeness and trustworthiness, many leading brands and manufacturers have demonstrated their commitment to quality through extensive testing and certification processes. Compliance with international standards such as ISO and DIN ensures that these rollers meet the stringent benchmarks required for operational safety and efficiency. Companies that invest in high-quality rubber disc return rollers often experience a return on investment through reduced maintenance costs and enhanced system uptime. Moreover, rubber disc return rollers are also aligned with environmental sustainability goals. Their durable construction reduces the frequency of replacements, thus minimizing waste. Some manufacturers have gone a step further by utilizing recycled rubber in their production processes, contributing to ecological conservation. Practical tips for optimizing the use of rubber disc return rollers include regular inspection and maintenance schedules. Routine checks for wear and any signs of damage can prevent potential operational disruptions. Ensuring that the rollers are correctly aligned and secured can further promote system efficiency and longevity. To sum up, rubber disc return rollers are an essential component in any well-functioning conveyor system. Their specialized design not only enhances belt performance and reliability but also provides cost-effective and environmentally sustainable solutions for various industries. By leveraging expertise in selection, installation, and maintenance, organizations can harness the full potential of these critical assets, establishing a robust foundation for streamlined and productive operations.

Latest news

-

The Unrivaled Performance of Polyurethane Pulleys in Industrial ApplicationsNewsAug.25,2025

-

The Critical Role of Drum Lagging in Conveyor SystemsNewsAug.25,2025

-

Navigating Industrial Efficiency: The Critical Role of Conveyor PulleysNewsAug.25,2025

-

InIntroduction to Advanced Pulley Lagging SolutionsNewsAug.25,2025

-

Industry Trends in Pulley Lagging TechnologyNewsAug.25,2025

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

OUR PRODUCTS