Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

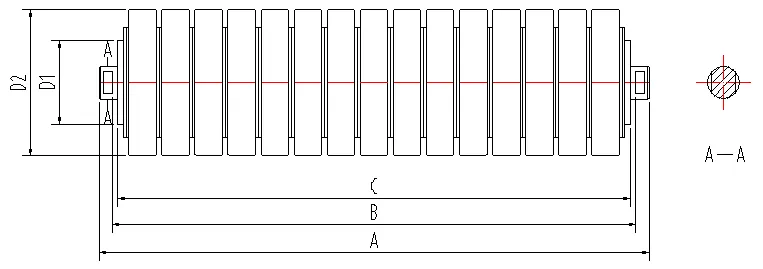

Zulu return roller for conveyor belt

Understanding Return Rollers for Conveyor Belts

Conveyor belts are essential components in various industries, facilitating the transportation of materials and products efficiently and safely. Among the critical components of a conveyor system is the return roller, a component that often goes unnoticed but plays a crucial role in the system's overall functionality. This article delves into the significance, types, and maintenance of return rollers in conveyor belts.

The Role of Return Rollers

Return rollers serve to support the conveyor belt's return segment. After materials are loaded and transported, the belt must return to the starting point for the next cycle. Return rollers are strategically placed beneath the conveyor belt to help maintain the belt's alignment and reduce wear and tear. By ensuring that the belt maintains proper tension and alignment, return rollers enhance the overall efficiency of the conveyor system, minimizing downtime and enhancing productivity.

Types of Return Rollers

Return rollers come in various shapes and types to suit different types of conveyor systems and applications. Understanding these variations is essential for selecting the right return roller for a specific setup.

1. Standard Return Rollers These are made of metal and are designed to carry the weight of the return belt. They are typically simple cylindrical rollers that provide fundamental support.

2. Impact Return Rollers When heavy materials are transported, the belt may experience impact shocks. Impact return rollers are designed with cushioning to absorb these shocks, reducing potential damage to the belt and rollers. They are particularly useful in applications involving abrasive materials or heavy loads.

3. Self-Cleaning Return Rollers In applications where sticky or wet materials could adhere to the roller surface, self-cleaning rollers are beneficial. These rollers have a design that allows them to shed material and remain clear during operation, thus preventing material buildup that could lead to operational issues.

return roller for conveyor belt

4. Idler Rollers Though primarily used for supporting the belt, these rollers also act as return rollers in some systems. Their design may vary based on the specific requirements of the conveyor system they are a part of.

Importance of Maintenance

Regular maintenance and inspection of return rollers are essential for the longevity of conveyor systems. Over time, return rollers can wear down, become misaligned, or even fail, leading to increased operational costs and safety concerns.

1. Regular Inspections Operators should routinely assess the condition of return rollers. Checking for wear, alignment, and any signs of damage can help identify issues before they lead to serious problems.

2. Lubrication Many return rollers require regular lubrication to operate smoothly. Proper lubrication helps reduce friction, thereby prolonging the life of both the roller and the conveyor belt.

3. Replacing Worn Rollers It’s crucial to replace worn or damaged return rollers promptly. Continued operation with compromised rollers can result in additional wear on the conveyor belt and other components, leading to costly repairs down the line.

4. Cleaning Keeping return rollers clean ensures they function correctly. Built-up debris and materials can affect the roller's performance, potentially causing it to lose alignment or grip.

Conclusion

In summary, return rollers play an indispensable role in the efficient operation of conveyor belt systems. Their function in supporting the returning segment of the belt and ensuring proper alignment is vital for maintaining productivity in various industrial applications. Understanding the different types of return rollers, as well as the necessity of regular maintenance, is crucial for anyone working with conveyor systems. By paying attention to these components, businesses can enhance material handling efficiency and ensure a smoother operation, ultimately leading to higher productivity and reduced operational costs.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025