Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu types of conveyor belt rollers

Types of Conveyor Belt Rollers

Conveyor belt systems are integral to many industries, ranging from manufacturing to mining, where they are used to transport materials efficiently. A crucial component of these systems is conveyor belt rollers. These rollers support the belt and facilitate the movement of materials, which can have a significant impact on the system's overall efficiency and productivity. Understanding the different types of conveyor belt rollers can help in selecting the appropriate roller for specific applications, ensuring optimal performance.

1. Idler Rollers

Idler rollers are perhaps the most common type found in conveyor systems. They provide support to the conveyor belt between the drives and loading points. These rollers do not transmit power; instead, they serve to stabilize and evenly distribute the load on the belt. Idler rollers come in various configurations, including flat, rubber-coated, and trough-shaped designs. The choice of idler roller can depend on several factors, including the type of material being transported, the load capacity required, and environmental conditions.

2. Drive Rollers

Drive rollers are essential for propelling the conveyor belt forward. These rollers are equipped with a motor that provides the necessary force to move the belt and the materials it carries. Drive rollers can be found at one end of the conveyor system and are typically designed to create friction with the belt to ensure effective motion. Key factors affecting drive roller performance include the roller's diameter, surface texture, and material composition.

Return rollers are utilized to support the belt on its return trip from the discharge end back to the load point. They play a crucial role in maintaining the integrity of the belt and preventing sagging, which can lead to inefficient operation and premature wear. Return rollers are generally placed in a straight alignment along the idle side of the conveyor system. Some designs come equipped with rubber coatings to reduce noise and minimize wear on the belt.

types of conveyor belt rollers

4. Impact Rollers

In scenarios where materials are loaded onto a conveyor belt, impact rollers are utilized to cushion the fall and reduce the risk of damage to both the belt and the rollers themselves. These rollers are often found at the loading zones where heavy materials are transferred onto the belt. They feature a special design that can absorb shock, which helps maintain the conveyor's operational efficiency and extends its lifespan.

5. Washing Rollers

Washing rollers are specialized rollers that play a crucial role in certain manufacturing processes where cleanliness is essential. These rollers are designed to facilitate the cleaning of the conveyor belt while in motion, ensuring that materials do not contaminate the product during transport. They are particularly useful in the food processing industry.

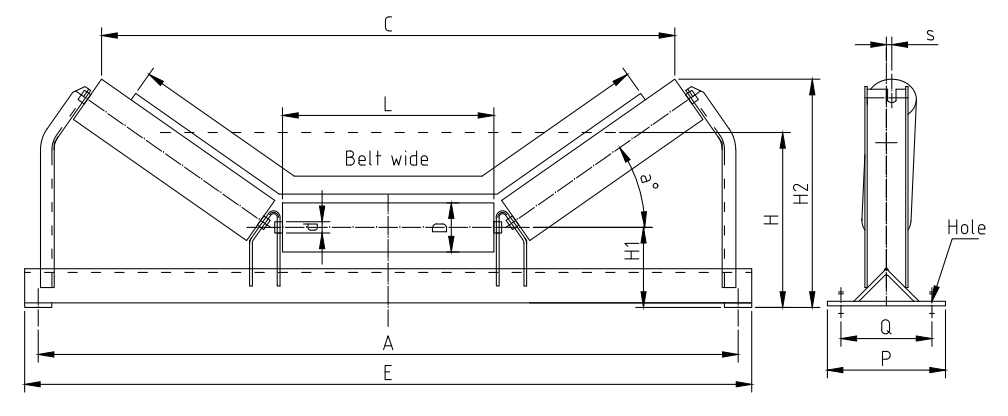

6. Trough Rollers

Trough rollers are designed to hold the conveyor belt in a trough shape, which helps to contain the material and prevent spillage. Troughing (the act of curving the belt) increases load capacity and minimizes material loss, especially for bulk products. Trough rollers are often adjustable, allowing operators to customize the angle based on the specific requirements of the application.

Conclusion

Selecting the right type of conveyor belt roller significantly influences the efficiency, safety, and lifespan of a conveyor system. As industries continue to evolve and demand higher productivity levels, innovative roller designs and materials will play a pivotal role in enhancing conveyor performance. By understanding the various types of conveyor rollers available, businesses can make informed decisions, leading to improved operational efficiency and reduced maintenance costs. Whether it's an idler, drive, return, or specialty roller, each roller type has its specific function, and recognizing these differences is key to optimizing any conveyor operation.

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025