Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu جون . 25, 2024 03:04

Back to list

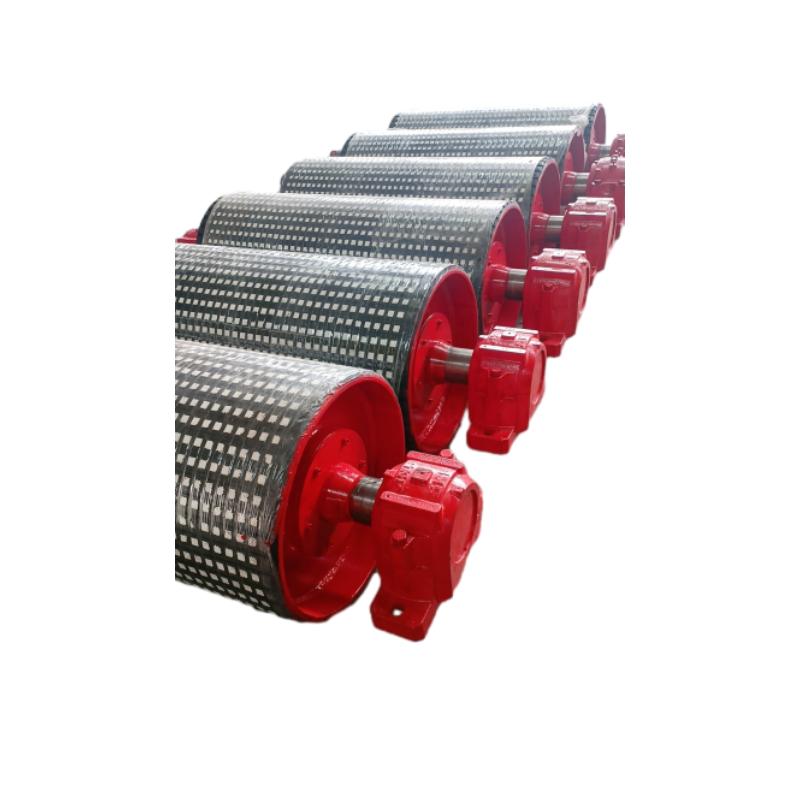

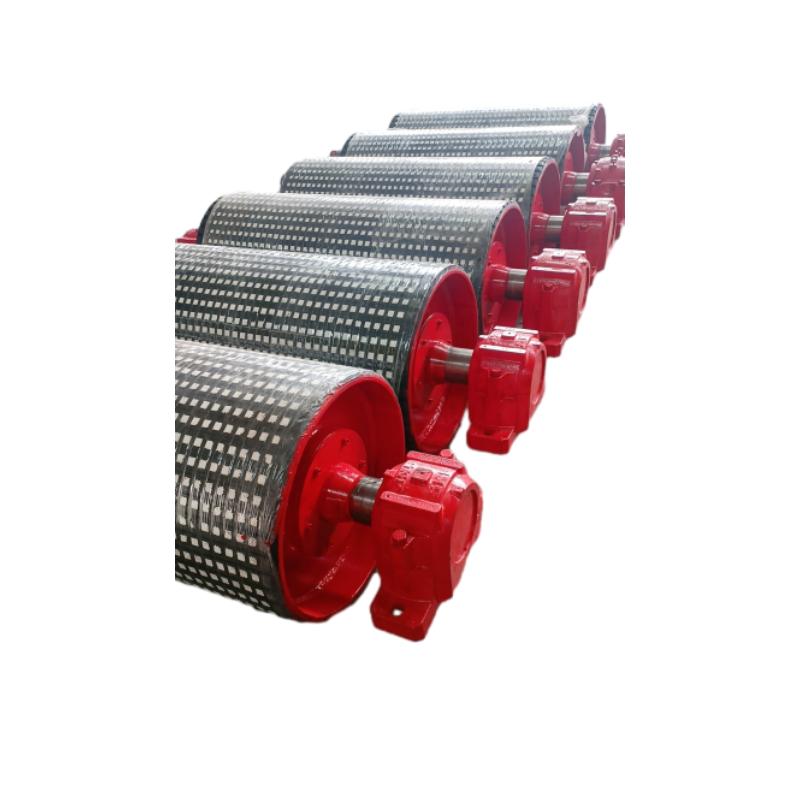

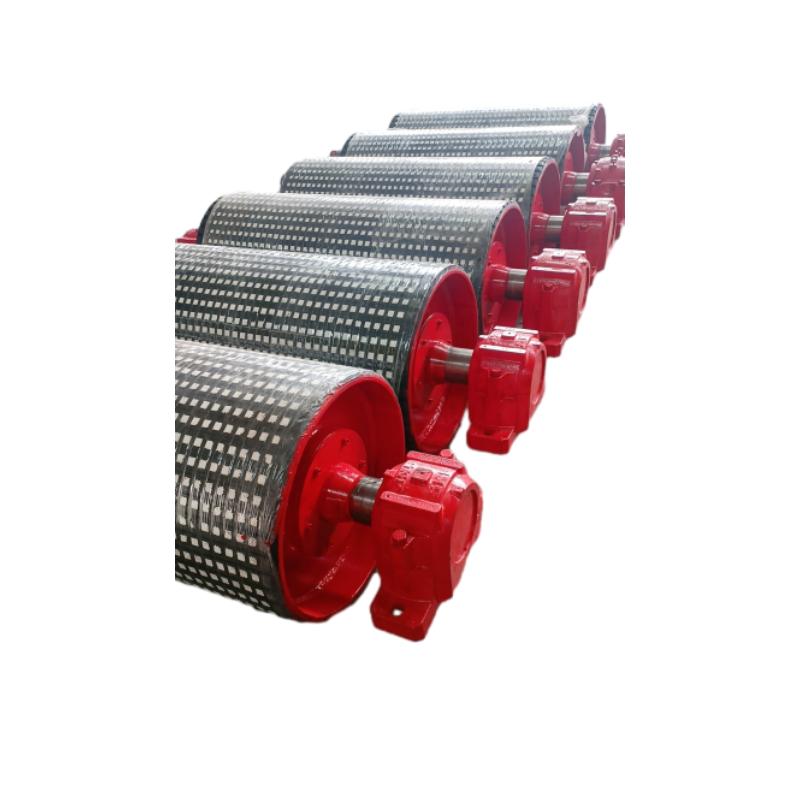

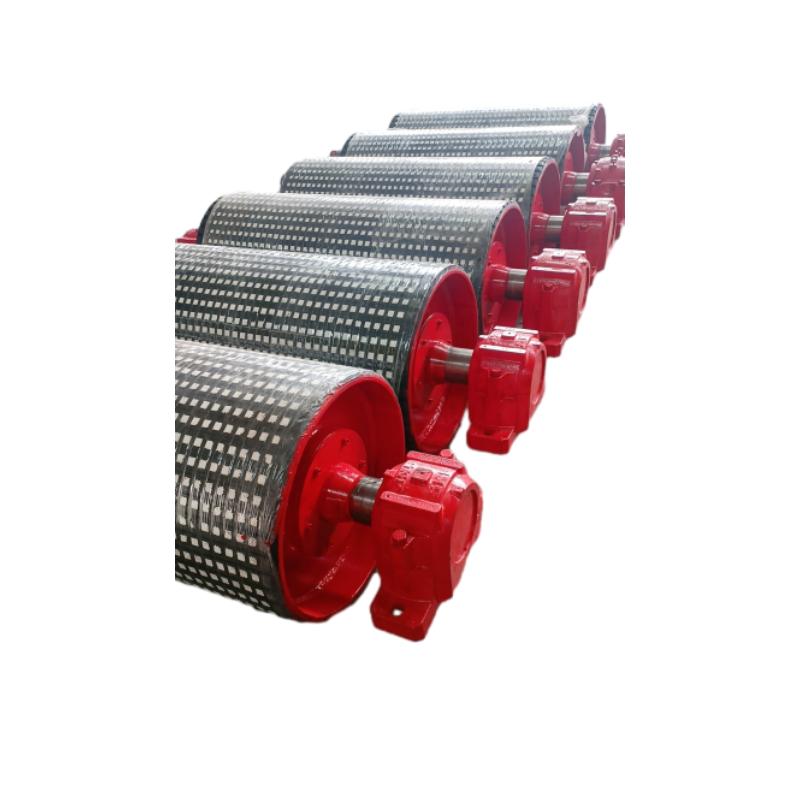

Efficient Conveyor Roller System A Comprehensive Guide for Industry Applications

The Role and Efficiency of Conveyor Guide Rollers A Comprehensive Overview

In the bustling world of material handling and industrial automation, conveyor guide rollers play a pivotal role in ensuring smooth and efficient flow of goods. Often unseen but indispensable, these small yet critical components form the backbone of many manufacturing and logistics systems.

A conveyor guide roller, essentially, is a cylindrical component designed to maintain the alignment and direction of a conveyor belt as it moves materials from one point to another. They are typically made of durable materials like steel, stainless steel, or high-impact plastic, depending on the application's requirements. The primary function of guide rollers is to minimize lateral movement, preventing the belt from veering off course and maintaining constant speed, thus enhancing productivity.

The design of guide rollers varies, ranging from simple single-axis rollers to more advanced multi-axis designs that can accommodate different angles and movements. Their shape, such as straight, curved, or incline, is tailored to suit the specific conveyor layout and the nature of the transported items. For instance, flat-top rollers are ideal for conveying flat surfaces, while V-shaped rollers are suitable for handling heavy loads or materials with irregular shapes.

Efficiency is a key consideration when evaluating conveyor guide rollers. Well-designed rollers reduce friction, minimizing energy loss and extending the lifespan of both the belt and the roller itself. High-quality bearings ensure minimal wear and tear, contributing to the overall system's reliability High-quality bearings ensure minimal wear and tear, contributing to the overall system's reliability High-quality bearings ensure minimal wear and tear, contributing to the overall system's reliability High-quality bearings ensure minimal wear and tear, contributing to the overall system's reliability

High-quality bearings ensure minimal wear and tear, contributing to the overall system's reliability High-quality bearings ensure minimal wear and tear, contributing to the overall system's reliability conveyor guide rollers. Moreover, proper maintenance, including regular lubrication and timely replacement, ensures optimal performance and prevents potential disruptions in the production line.

Innovations in technology have also improved guide rollers, introducing features like self-aligning capabilities and anti-static properties to handle delicate or sensitive materials without damage. These advancements cater to the diverse needs of modern industries, from food processing to pharmaceuticals and e-commerce fulfillment centers.

Safety is another aspect that cannot be overlooked. Smooth operation and minimal risks of pinch points or entanglement are crucial, and well-designed guide rollers contribute significantly to this aspect. They are often equipped with safety guards to prevent accidental contact, ensuring a safer working environment for operators.

In conclusion, conveyor guide rollers are the silent heroes of the industrial landscape, their ensuring the seamless movement of goods across vast distances. Their efficiency, adaptability, and continuous evolution reflect the ever-evolving demands of modern manufacturing and logistics. By understanding and optimizing their function, businesses can streamline their processes, reduce costs, and ultimately drive productivity to new heights.

conveyor guide rollers. Moreover, proper maintenance, including regular lubrication and timely replacement, ensures optimal performance and prevents potential disruptions in the production line.

Innovations in technology have also improved guide rollers, introducing features like self-aligning capabilities and anti-static properties to handle delicate or sensitive materials without damage. These advancements cater to the diverse needs of modern industries, from food processing to pharmaceuticals and e-commerce fulfillment centers.

Safety is another aspect that cannot be overlooked. Smooth operation and minimal risks of pinch points or entanglement are crucial, and well-designed guide rollers contribute significantly to this aspect. They are often equipped with safety guards to prevent accidental contact, ensuring a safer working environment for operators.

In conclusion, conveyor guide rollers are the silent heroes of the industrial landscape, their ensuring the seamless movement of goods across vast distances. Their efficiency, adaptability, and continuous evolution reflect the ever-evolving demands of modern manufacturing and logistics. By understanding and optimizing their function, businesses can streamline their processes, reduce costs, and ultimately drive productivity to new heights.

High-quality bearings ensure minimal wear and tear, contributing to the overall system's reliability High-quality bearings ensure minimal wear and tear, contributing to the overall system's reliability

High-quality bearings ensure minimal wear and tear, contributing to the overall system's reliability High-quality bearings ensure minimal wear and tear, contributing to the overall system's reliability conveyor guide rollers. Moreover, proper maintenance, including regular lubrication and timely replacement, ensures optimal performance and prevents potential disruptions in the production line.

Innovations in technology have also improved guide rollers, introducing features like self-aligning capabilities and anti-static properties to handle delicate or sensitive materials without damage. These advancements cater to the diverse needs of modern industries, from food processing to pharmaceuticals and e-commerce fulfillment centers.

Safety is another aspect that cannot be overlooked. Smooth operation and minimal risks of pinch points or entanglement are crucial, and well-designed guide rollers contribute significantly to this aspect. They are often equipped with safety guards to prevent accidental contact, ensuring a safer working environment for operators.

In conclusion, conveyor guide rollers are the silent heroes of the industrial landscape, their ensuring the seamless movement of goods across vast distances. Their efficiency, adaptability, and continuous evolution reflect the ever-evolving demands of modern manufacturing and logistics. By understanding and optimizing their function, businesses can streamline their processes, reduce costs, and ultimately drive productivity to new heights.

conveyor guide rollers. Moreover, proper maintenance, including regular lubrication and timely replacement, ensures optimal performance and prevents potential disruptions in the production line.

Innovations in technology have also improved guide rollers, introducing features like self-aligning capabilities and anti-static properties to handle delicate or sensitive materials without damage. These advancements cater to the diverse needs of modern industries, from food processing to pharmaceuticals and e-commerce fulfillment centers.

Safety is another aspect that cannot be overlooked. Smooth operation and minimal risks of pinch points or entanglement are crucial, and well-designed guide rollers contribute significantly to this aspect. They are often equipped with safety guards to prevent accidental contact, ensuring a safer working environment for operators.

In conclusion, conveyor guide rollers are the silent heroes of the industrial landscape, their ensuring the seamless movement of goods across vast distances. Their efficiency, adaptability, and continuous evolution reflect the ever-evolving demands of modern manufacturing and logistics. By understanding and optimizing their function, businesses can streamline their processes, reduce costs, and ultimately drive productivity to new heights. Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS