Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu High-Performance Mining Conveyor Pulleys for Enhanced Material Handling

Mining Conveyor Pulleys Essential Components for Material Handling

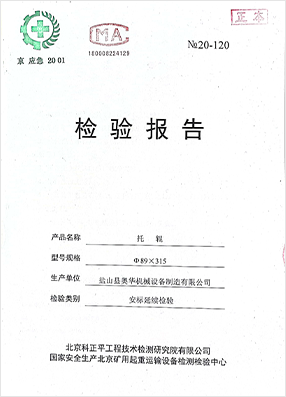

In the mining industry, efficient bulk material handling is crucial for maximizing productivity and minimizing operational costs. One of the key components that plays a vital role in this process is the conveyor pulley. Mining conveyor pulleys are critical for the smooth operation of conveyor systems, which transport materials such as ore, coal, and minerals from one location to another within the mine.

Understanding Conveyor Pulleys

Conveyor pulleys are cylindrical devices that provide the necessary support and drive for conveyor belts. They come in different types and sizes, tailored to specific applications and operational requirements. The primary functions of conveyor pulleys are to drive the conveyor belt, support the belt’s weight, and change the direction of the material flow.

Types of Conveyor Pulleys

There are several types of conveyor pulleys used in mining operations, including drive pulleys, tail pulleys, and bend pulleys

.1. Drive Pulleys These are responsible for propelling the conveyor belt and are typically located at the head end of the conveyor. They are mounted on a shaft that is connected to a motor, which provides the necessary power to move the belt and transport materials.

mining conveyor pulleys

2. Tail Pulleys Located at the opposite end of the conveyor from the drive pulley, tail pulleys provide tension to the conveyor belt, ensuring it remains taut during operation. This is essential to prevent slippage and maintain efficient material handling.

3. Bend Pulleys These pulleys are used to change the direction of the conveyor belt. They allow for flexibility in conveyor system design, enabling belts to navigate around obstacles or to fit within spatial constraints.

Materials and Design Considerations

The design and material selection for mining conveyor pulleys are critical for ensuring durability and reliability. Pulleys are typically made from robust materials, such as steel or high-strength composites, that can withstand harsh environmental conditions, including exposure to moisture, dust, and extreme temperatures. The surface of the pulley is often coated or treated to enhance resistance to wear and corrosion.

Moreover, the proper alignment and installation of conveyor pulleys are crucial for maintaining system efficiency. Misalignment can lead to uneven wear, increased energy consumption, and potential system failure. Regular maintenance, including inspections and adjustments, is essential to prolong the life of the pulleys and overall conveyor system.

Conclusion

In summary, mining conveyor pulleys are indispensable components in the bulk material handling process. By understanding their types, functions, and design considerations, mining operations can ensure optimal performance and reliability of their conveyor systems. As the mining industry continues to evolve, the importance of advanced and durable conveyor technologies, including pulleys, will only grow, driving improvements in efficiency and reducing operational costs. Investing in high-quality conveyor pulleys is a strategic decision that can significantly enhance productivity in mining operations.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025