Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu مارت . 05, 2025 04:41

Back to list

bend pulley

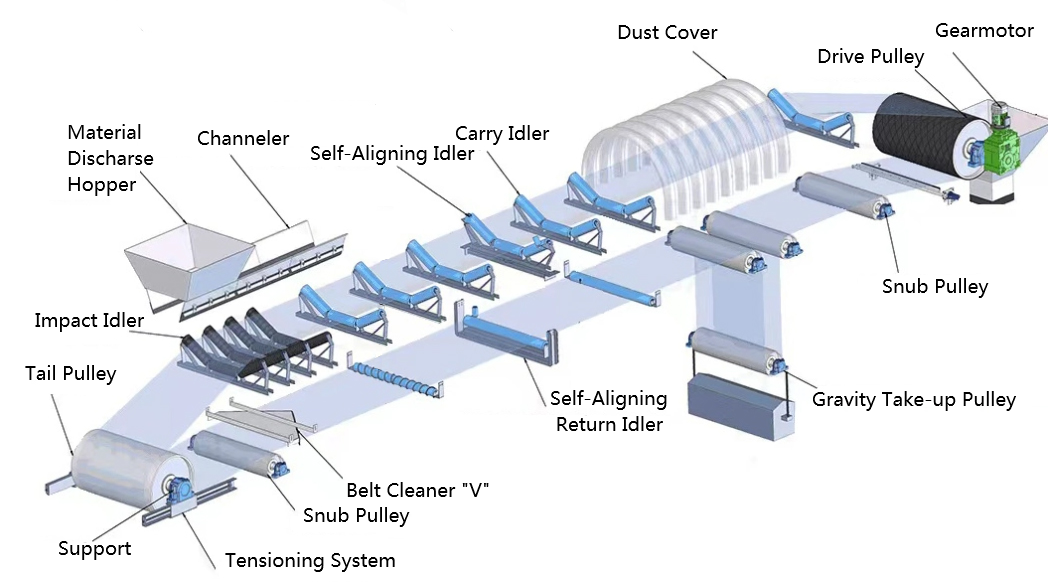

Pulley tail systems have revolutionized various industries, offering a sophisticated approach to mechanical operations. These systems are not only essential in lifting and transporting heavy loads but also play a critical role in enhancing the efficiency of production lines and engineering tasks. Their unique design addresses complex mechanical challenges, making them indispensable in fields ranging from construction to advanced manufacturing.

Authoritativeness in the pulley tail industry stems from decades of development and application in various complex scenarios. Industry leaders in mechanical systems often consult with seasoned pulley tail experts to design custom solutions tailored to distinct operational challenges. These professionals not only bring theoretical knowledge but also years of hands-on experience, having worked with a wide array of systems across different sectors. Their authority is further established by patented innovations and their role in setting industry standards and safety protocols. Trustworthiness in a pulley tail system is paramount, as these mechanisms often bear the weight of substantial loads and are critical to the safety and efficiency of operations. Reliability is built into the design through rigorous testing and quality control measures. Trusted manufacturers guarantee their products through certifications and adherence to international safety standards. When selecting a pulley tail system, discerning customers assess both the reputation of the manufacturer and the system’s track record in real-world applications. This trust is often bolstered by case studies that highlight not only successful implementations but also the proactive handling of challenges. In summary, pulley tail systems are more than just components in mechanical setups; they are pivotal to enhancing operational efficiencies in challenging environments. Their impact is evidenced by improved productivity and reduced operational risks. With expert design, authoritative knowledge, and reliable performance, these systems provide a robust solution to mechanical challenges, standing as a testament to their critical role in modern industry. As technology advances, the evolution of pulley tail systems continues to push the boundaries of what mechanical systems can achieve, embracing new materials and smarter designs for even greater efficacy in the future.

Authoritativeness in the pulley tail industry stems from decades of development and application in various complex scenarios. Industry leaders in mechanical systems often consult with seasoned pulley tail experts to design custom solutions tailored to distinct operational challenges. These professionals not only bring theoretical knowledge but also years of hands-on experience, having worked with a wide array of systems across different sectors. Their authority is further established by patented innovations and their role in setting industry standards and safety protocols. Trustworthiness in a pulley tail system is paramount, as these mechanisms often bear the weight of substantial loads and are critical to the safety and efficiency of operations. Reliability is built into the design through rigorous testing and quality control measures. Trusted manufacturers guarantee their products through certifications and adherence to international safety standards. When selecting a pulley tail system, discerning customers assess both the reputation of the manufacturer and the system’s track record in real-world applications. This trust is often bolstered by case studies that highlight not only successful implementations but also the proactive handling of challenges. In summary, pulley tail systems are more than just components in mechanical setups; they are pivotal to enhancing operational efficiencies in challenging environments. Their impact is evidenced by improved productivity and reduced operational risks. With expert design, authoritative knowledge, and reliable performance, these systems provide a robust solution to mechanical challenges, standing as a testament to their critical role in modern industry. As technology advances, the evolution of pulley tail systems continues to push the boundaries of what mechanical systems can achieve, embracing new materials and smarter designs for even greater efficacy in the future.

Next:

Latest news

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025

OUR PRODUCTS