Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu feeder idler

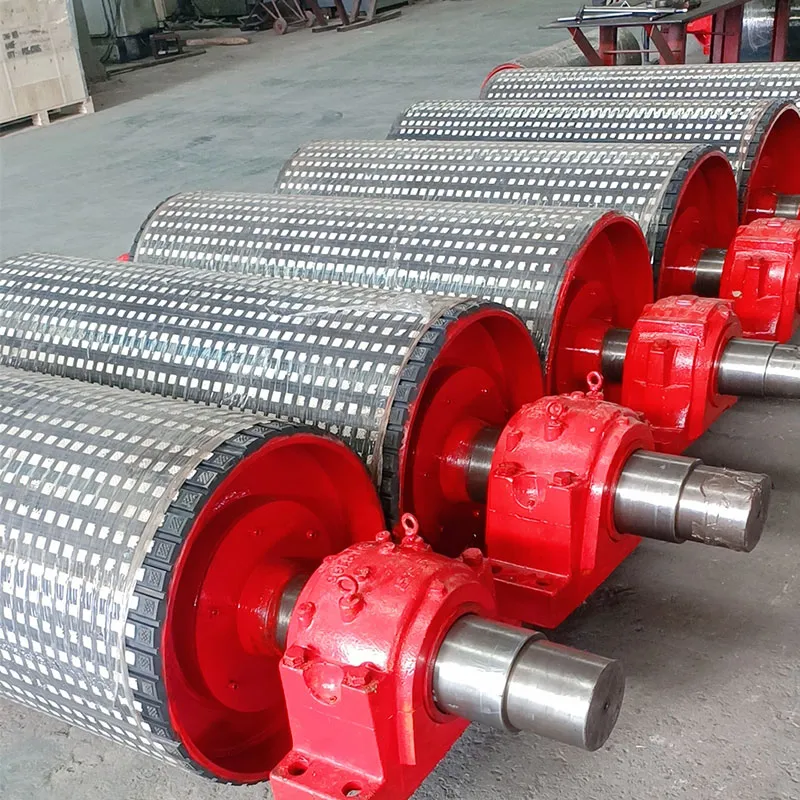

Understanding the Role of Feeder Idlers in Conveyor Systems

In the realm of material handling and transportation, efficiency and reliability are paramount. Among the many components that contribute to a well-functioning conveyor system, feeder idlers play a crucial yet often overlooked role. These components are vital in ensuring the smooth operation of conveyor belts, particularly in industries such as mining, agriculture, and manufacturing. This article aims to explore the significance, functionality, and types of feeder idlers, providing a comprehensive understanding of their importance in modern industrial setups.

What are Feeder Idlers?

Feeder idlers are support rollers located along the conveyor system, specifically designed to maintain the position of the conveyor belt while also aiding in the loading and transfer of materials. They are typically situated at the area where the material enters the conveyor system, serving as a guide for the belt and the load it carries. By stabilizing the belt, feeder idlers help in achieving optimal performance levels and reducing wear and tear on both the belt and the conveying system.

The Functionality of Feeder Idlers

The primary functions of feeder idlers can be broken down into a few key areas

1. Load Balancing As materials are loaded onto the conveyor belt, feeder idlers distribute the weight evenly across the belt. This balance is essential to prevent sagging or excessive strain on any given section of the belt, which could lead to premature wear or even catastrophic failure.

2. Belt Tracking Feeder idlers help maintain the proper alignment of the conveyor belt. Misalignment can result in material spillage, reduced efficiency, and increased maintenance costs. By ensuring that the belt moves correctly along the intended path, feeder idlers contribute to a seamless operation.

3. Material Flow Management The design of feeder idlers allows for controlled material flow from one point to another. They can facilitate the gradual release of materials onto the conveyor, preventing sudden surges that could overwhelm the system or disrupt the consistent flow of products.

feeder idler

4. Reduction of Friction By providing a smooth surface for the conveyor belt to ride on, feeder idlers minimize friction. This reduction in friction not only enhances the lifespan of the conveyor system but also improves energy efficiency, as less power is required to move the material.

Types of Feeder Idlers

Feeder idlers come in various designs, each suited to different applications and environments. Here are some common types

1. Flat Idlers These are the most basic type and are designed for conventional applications where the conveyor belt operates in a horizontal plane. They provide support and stability for the belt and are commonly used in bulk material handling systems.

2. Trough Idlers These have a curved design that helps contain materials on the belt, especially when dealing with loose and granular products. The trough shape is effective in preventing spillage and improving load-bearing capacity.

3. Return Idlers Typically positioned on the return side of the conveyor belt, these idlers support the weight of the belt and can assist in maintaining the belt’s shape. They can also help in ensuring a consistent alignment as the belt returns to the loading point.

4. Self-Cleaning Idlers Ideal for handling sticky or wet materials, self-cleaning idlers are designed to prevent the accumulation of debris and materials on the idler surface. This feature is particularly beneficial in mining and agricultural applications where product adherence can be an issue.

Conclusion

In summary, feeder idlers are an essential component of conveyor systems, playing a pivotal role in ensuring efficiency, stability, and reliability in material handling processes. Understanding their functions and types can help industries select the most appropriate solutions for their specific needs, ultimately improving productivity and decreasing operational costs. As technology continues to advance, the design and functionality of feeder idlers will likely evolve, further enhancing their contribution to modern industrial operations.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025