Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

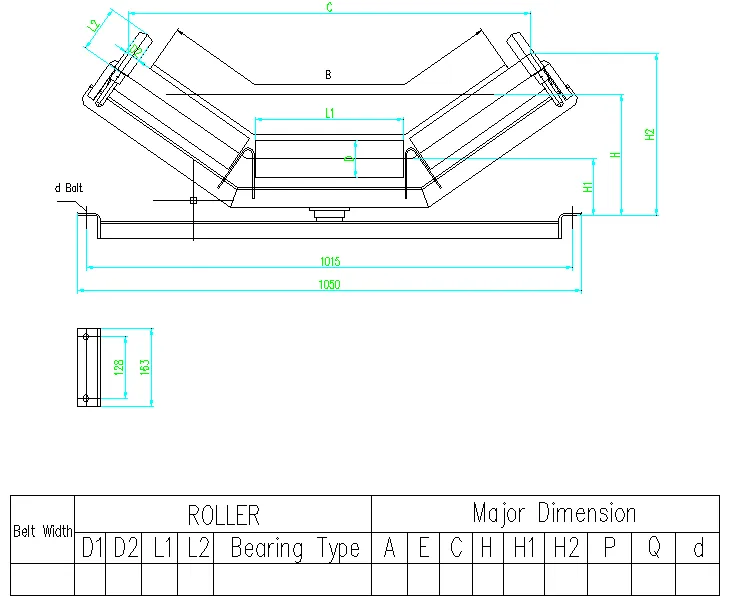

Zulu cushion roller

The Importance of Cushion Rollers in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, efficiency and precision are the cornerstones of competitive advantage. Among the many innovations that have emerged to enhance production processes, cushion rollers stand out as a crucial component in ensuring smooth operations. This article delves into the importance of cushion rollers, their applications, and the benefits they bring to various industries.

What are Cushion Rollers?

Cushion rollers are specialized conveyor components designed to facilitate the movement of materials along production lines. Unlike traditional rollers, cushion rollers incorporate a cushioning mechanism that absorbs shock and minimizes impact as products are transported. This unique feature not only enhances the durability of the materials being moved but also protects the equipment from wear and tear.

Applications Across Industries

Cushion rollers are versatile and find applications in multiple sectors, including automotive, packaging, food and beverage, and electronics. In the automotive industry, for example, they are used to move heavy components through several assembly lines, ensuring that delicate parts are transported without damage. Similarly, in the packaging sector, cushion rollers facilitate the smooth transfer of goods, reducing the risk of breakage and ensuring products reach their destination intact.

In the food and beverage industry, hygiene is paramount. Cushion rollers help maintain stringent cleanliness standards by supporting easy cleaning processes and preventing contamination. By using materials that are resistant to corrosion and bacteria, manufacturers can ensure that their conveyor systems meet safety regulations while also enhancing operational efficiency.

The electronics industry benefits from cushion rollers by utilizing them in assembly lines that require the delicate handling of electronic components

. The shock-absorbing nature of the rollers prevents static damage, a significant concern when dealing with sensitive electronic equipment.Benefits of Using Cushion Rollers

cushion roller

1. Reduced Product Damage One of the hallmark advantages of cushion rollers is their ability to minimize product damage during transport. The cushioning effect absorbs shocks, making it particularly beneficial for fragile items.

2. Extended Equipment Lifespan By reducing the impact on both products and conveyor systems, cushion rollers contribute to an extended lifespan for the equipment used in production. This translates to lower maintenance costs and less frequent need for replacements.

3. Noise Reduction The cushioning mechanisms in these rollers also help mitigate noise generated during operation. This is especially important in environments where excessive noise can lead to worker discomfort and decreased productivity.

4. Versatility Cushion rollers can be customized for various applications, enhancing their utility across different industries. They can be designed to accommodate various load capacities and dimensions, making them suitable for numerous production environments.

5. Improved Workflow Efficiency With their smooth operation, cushion rollers contribute to streamlined workflows. The ability to transport products without interruption ensures that production processes remain efficient and timely.

6. Enhanced Safety Reducing the risk of product spills and breakdowns not only protects the goods but also safeguards employees working alongside production machinery. This enhances the overall safety of the work environment.

Conclusion

In conclusion, cushion rollers are an integral part of modern manufacturing processes, offering numerous advantages that help companies improve efficiency, reduce waste, and enhance product safety. As industries continue to seek ways to optimize operations and respond to the demands of a competitive market, the adoption of innovative solutions like cushion rollers will remain pivotal. By investing in such technologies, manufacturers can ensure that they not only meet current market demands but also position themselves for future growth and sustainability.

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025