Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

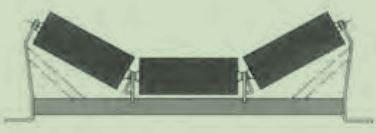

Zulu conveyor bend pulley

The Role of Conveyor Bend Pulleys in Industrial Operations

In the modern industrial landscape, efficiency and reliability are paramount, especially in bulk material handling. One key component that significantly contributes to the smooth operation of conveyor systems is the bend pulley. Conveyors are widely used in various sectors, including mining, manufacturing, and logistics, primarily for their ability to transport large volumes of materials over considerable distances. Bend pulleys play a crucial role in enhancing the performance and longevity of these conveyor systems.

What is a Bend Pulley?

A bend pulley is a type of pulley used in conveyor systems to change the direction of the belt. Positioned at a certain angle, the bend pulley ensures that the belt maintains optimal tension and reduces the risk of sagging. These pulleys are typically located at the load and return sides of the conveyor. Depending on the design, a bend pulley can be a single or double pulley set up, allowing for different angles of belt deviation.

Importance of Bend Pulleys

1. Belt Orientation and Alignment One of the primary roles of a bend pulley is to guide the belt in the desired direction. Proper alignment is essential as it minimizes wear and tear on the belt, ensuring a longer service life. Misalignment can lead to uneven wear, which might ultimately cause the belt to fail.

2. Tension Control Maintaining adequate tension in the conveyor belt is crucial for its effective operation. Bend pulleys contribute to this tension by providing a point at which the belt can bend and thus remain taut. This tension helps in the effective transfer of materials along the conveyor system.

3. Space Efficiency By allowing the belt to change direction, bend pulleys enable more compact conveyor designs. This is particularly beneficial in environments where space is limited, as it allows for a more flexible layout.

conveyor bend pulley

4. Material Handling Efficiency The efficiency of material handling systems improves significantly with the incorporation of bend pulleys. They allow for contouring around obstacles and navigating tight spaces, ensuring materials can be transported seamlessly from one location to another.

Types of Bend Pulleys

Bend pulleys come in various designs, depending on the specific application and operational requirements. Common types include

- Concave Bend Pulleys These pulleys have a curved surface that helps to maintain a tight grip on the conveyor belt, improving traction and efficiency. - Flat Bend Pulleys These provide a straightforward, flat surface that works well in situations where minimal belt deviation is required.

- Trough Bend Pulleys Designed with a trough shape, these pulleys help keep the load securely in place, reducing spillage and ensuring efficient material transport.

Conclusion

Bend pulleys may seem like a minor component of a conveyor system, but their function is vital in ensuring optimal performance and durability. By helping to maintain proper belt alignment, tension, and space efficiency, they contribute significantly to the reliability of material handling operations. As industries continue to evolve and demand greater efficiency, the role of bend pulleys will undoubtedly increase, making them an essential component in the mechanical ecosystems of modern industry. Understanding their function and application is key to designing effective and efficient conveyor systems that meet today’s operational demands.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025