Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu فېۋرال . 12, 2025 16:41

Back to list

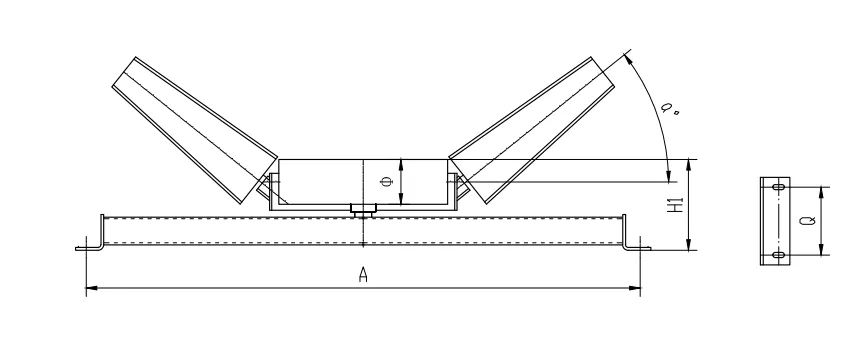

Customized Roller

Conveyor belt rolls play a crucial role in various industries, forming the backbone of material handling systems. To maximize the efficiency and longevity of these systems, it's imperative to understand their unique features, applications, and maintenance needs. With over two decades of experience optimizing conveyor systems for industries ranging from manufacturing to logistics, I offer insights into the essential aspects one must consider when dealing with conveyor belt rolls.

For businesses looking to upgrade or maintain their conveyor systems, investing in quality certification and adherence to industry standards cannot be overstated. ISO certification, for example, is a testament to a roll's quality, indicating it has passed rigorous assessment and meets international benchmarks. Expert consultation on the compliance processes can bolster a company's adherence to such standards, reinforcing trust with stakeholders. Incorporating technology into the management of conveyor belt rolls is another area where industries can benefit. Automated monitoring systems can provide real-time data on roll performance, allowing for immediate adjustments and predictive maintenance. Such innovations not only enhance efficiency but also reduce human error, ensuring that the industrial processes are seamless and consistent. Lastly, sourcing conveyor belt rolls from reputable manufacturers is crucial. Established companies with a proven track record of excellence are more likely to furnish products that offer not only operational efficiency but also peace of mind regarding quality and safety. Leveraging partnerships with such entities can be instrumental in driving business success. In conclusion, skimming over the details can lead to significant operational hitches when dealing with conveyor belt rolls. A comprehensive understanding of their design, application, and maintenance, coupled with adherence to quality standards and technological integration, ensures these vital components effectively support the broader industrial processes. With a commitment to expertise, authority, and trustworthiness, industries can redefine efficiency, propelling themselves to new operational heights.

For businesses looking to upgrade or maintain their conveyor systems, investing in quality certification and adherence to industry standards cannot be overstated. ISO certification, for example, is a testament to a roll's quality, indicating it has passed rigorous assessment and meets international benchmarks. Expert consultation on the compliance processes can bolster a company's adherence to such standards, reinforcing trust with stakeholders. Incorporating technology into the management of conveyor belt rolls is another area where industries can benefit. Automated monitoring systems can provide real-time data on roll performance, allowing for immediate adjustments and predictive maintenance. Such innovations not only enhance efficiency but also reduce human error, ensuring that the industrial processes are seamless and consistent. Lastly, sourcing conveyor belt rolls from reputable manufacturers is crucial. Established companies with a proven track record of excellence are more likely to furnish products that offer not only operational efficiency but also peace of mind regarding quality and safety. Leveraging partnerships with such entities can be instrumental in driving business success. In conclusion, skimming over the details can lead to significant operational hitches when dealing with conveyor belt rolls. A comprehensive understanding of their design, application, and maintenance, coupled with adherence to quality standards and technological integration, ensures these vital components effectively support the broader industrial processes. With a commitment to expertise, authority, and trustworthiness, industries can redefine efficiency, propelling themselves to new operational heights.

Next:

Latest news

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025

OUR PRODUCTS