Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu types of belt cleaners

Understanding the Different Types of Belt Cleaners

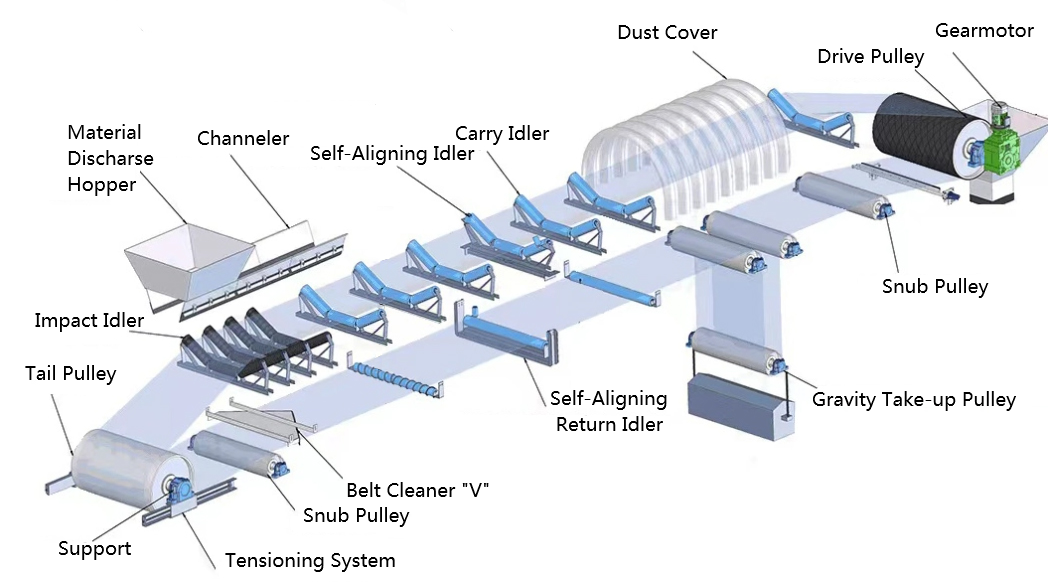

Belt cleaners play a crucial role in maintaining the efficiency and longevity of conveyor systems across various industries. As conveyor belts transport materials, they often accumulate debris, dust, and other contaminants. If left unchecked, this buildup can lead to reduced performance, increased downtime, and higher maintenance costs. To combat these issues, a variety of belt cleaners are available, each designed to address specific cleaning needs. Here, we will explore the different types of belt cleaners and their applications.

1. Primary Belt Cleaners

Primary belt cleaners are typically installed at the discharge point of a conveyor belt. Their main function is to remove the bulk of material that sticks to the belt after it has transported goods. These cleaners usually feature a robust design to handle heavy materials and high-impact situations. They can be made from various materials, including rubber, polyurethane, or metal, depending on the application and the type of materials being transported. One popular type of primary cleaner is the blade cleaner, which utilizes a blade-like edge that scrapes the belt surface, effectively dislodging stuck materials.

2. Secondary Belt Cleaners

Secondary belt cleaners work in conjunction with primary cleaners to capture any residual materials that may still adhere to the belt after the initial cleaning process. These cleaners are usually set up further down the conveyor, and they are essential for ensuring a clean belt surface. They often feature a more flexible design, allowing them to conform to the belt's contour and effectively remove smaller particles. One example of a secondary cleaner is the scraping cleaner, which operates similarly to a primary cleaner but is designed for fine cleaning.

types of belt cleaners

Modular belt cleaners are designed for conveyor systems that utilize modular plastic belts. These cleaners are specifically engineered to fit the dimensions and intricacies of modular belts, making them highly effective for cleaning while preventing damage to the belt's surface. They often include a series of adjustable components that allow for customization based on the specific requirements of the application. Modular cleaners can be used in environments where different materials may be transported, ensuring versatility and efficiency.

4. Specialty Belt Cleaners

In some applications, standard belt cleaners may not suffice. Specialty belt cleaners are designed for niche applications and specific industry requirements. Examples include cleaners that are resistant to chemicals, heat, or abrasive materials. Industries such as mining, food processing, and pharmaceuticals may require specialized cleaning solutions to meet regulatory or operational standards. These cleaners can be tailored to withstand harsh conditions and ensure that the conveyor belt remains in optimal working condition.

5. Automatic Belt Cleaners

With advancements in technology, automatic belt cleaners have emerged as an efficient solution for maintaining clean conveyor belts. These systems utilize sensors and automated controls to monitor the cleanliness of the belt and activate cleaning mechanisms as needed. Automatic cleaners help reduce labor costs and ensure consistent performance by eliminating human error. They are particularly beneficial in high-volume operations where manual cleaning would be impractical.

Conclusion

Choosing the right belt cleaner is essential for maximizing the efficiency of conveyor systems and minimizing maintenance costs. Understanding the different types of belt cleaners—primary, secondary, modular, specialty, and automatic—enables businesses to select the most appropriate solutions for their specific needs. By investing in the proper cleaning equipment, companies can enhance productivity, extend the lifespan of their conveyor belts, and ensure a safer working environment.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025