Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu tapered roller

Understanding Tapered Roller Bearings Design and Applications

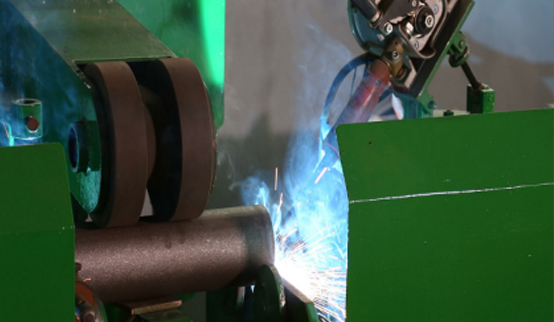

Tapered roller bearings are a type of rolling-element bearing that uses tapered inner and outer raceways to provide superior load-bearing capacity while reducing friction. These bearings are particularly valued in industries where heavy loads and rigid performance are critical. From automobiles to heavy machinery, tapered roller bearings play a crucial role in ensuring operational efficiency and reliability.

Design Features of Tapered Roller Bearings

The unique design of tapered roller bearings consists of an inner ring (cone), an outer ring (cup), and tapered rollers that are arranged in a way that allows them to distribute load over a larger surface area. The rollers are tapered to maintain a line contact with the raceways, which aids in handling both radial and axial loads. This design feature is particularly significant in applications where thrust forces are prevalent.

The angle of the taper is critical, as it affects the bearing's load capacity and performance characteristics. Generally, a greater taper angle increases the bearing's axial load-carrying capacity, while also optimizing alignment and performance under various loading conditions. The sizes of the rollers and the width of the bearing are also important design considerations, impacting the overall durability and effectiveness of the assembly.

Additionally, tapered roller bearings can be found in various configurations, including single-row, double-row, and four-row bearings, each serving specific applications and performance requirements. Single-row tapered roller bearings are commonly used in automotive applications and gearboxes, while double-row designs provide enhanced stability and load capabilities in heavy-duty industrial equipment.

Advantages of Tapered Roller Bearings

The primary advantage of tapered roller bearings is their ability to support both radial and axial loads simultaneously, making them ideal for diverse applications. This characteristic allows for a more compact design, enabling machinery to be more efficient and lightweight without sacrificing strength. Moreover, tapered roller bearings excel in handling heavy loads and are capable of operating at high speeds.

tapered roller

Another significant benefit is their durability. The tapered design allows for uniform stress distribution across the bearing surface, which minimizes wear and extends the bearing's lifespan. This durability translates into reduced maintenance costs and improved reliability in performance-critical applications.

Tapered roller bearings are also highly adaptable. They can be tailored to meet specific operational needs, including specialized coatings and materials that enhance performance in extreme conditions, such as high temperatures or corrosive environments. This versatility makes them essential in various sectors, including automotive, aerospace, construction, and manufacturing.

Applications of Tapered Roller Bearings

Tapered roller bearings are pivotal in the automotive industry, where they are used in wheel hubs, transmissions, and differentials. In these applications, the bearings must endure both longitudinal and lateral forces while maintaining high speed and efficiency.

In heavy machinery, such as excavators and loaders, tapered roller bearings are used in pivot points and drive mechanisms. Their ability to handle significant radial and axial loads helps maintain operational stability and prolongs equipment lifespan.

Additionally, tapered roller bearings are crucial in wind turbines, supporting the nacelle and rotor assembly where both high axial and radial loads occur due to wind pressure and inertia. The robust design ensures reliability and efficiency, which is vital in maximizing energy output and reducing downtime.

Conclusion

Tapered roller bearings represent a sophisticated blend of engineering design and functionality. Their unique ability to manage both radial and axial loads while maintaining operational reliability makes them an invaluable component across various industries. As technology continues to advance, further enhancements in material science and manufacturing techniques promise to increase the performance and longevity of tapered roller bearings. Understanding these bearings and their applications is essential for professionals involved in engineering and design, as they play an integral role in the efficiency and safety of modern machinery and vehicles.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025