Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu tapered conveyor rollers

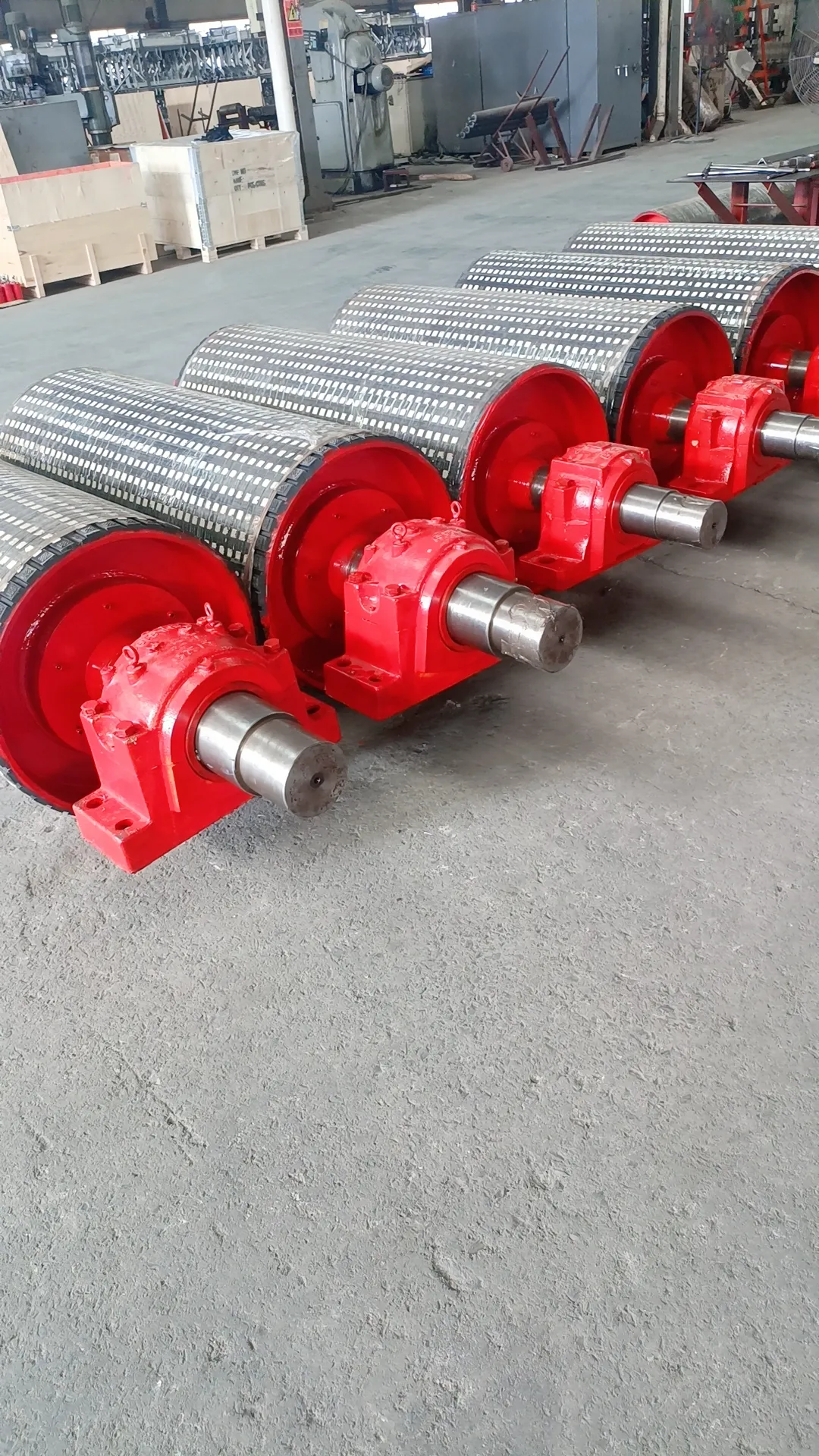

Understanding Tapered Conveyor Rollers Benefits and Applications

In the world of material handling and logistics, conveyor systems play a vital role in streamlining processes and increasing efficiency. Among the various components of conveyor systems, tapered conveyor rollers have gained significant attention due to their unique design and functionality. This article delves into the features, benefits, and applications of tapered conveyor rollers, shedding light on why they are an essential element in modern conveyor systems.

What Are Tapered Conveyor Rollers?

Tapered conveyor rollers are a specialized type of roller that features a conical shape, tapering from one end to the other. This design enables the roller to facilitate the movement of materials in a conveyor system more effectively. The taper can come in various angles, depending on the specific needs of the application, allowing for versatility in how goods are transported. While standard rollers are cylindrical, tapered rollers can help address various material handling challenges and optimize the flow of goods.

Benefits of Tapered Conveyor Rollers

1. Improved Load Distribution The tapered design allows for better load distribution across the roller. This feature reduces wear and tear on both the rollers and the conveyor system, ultimately extending the lifespan of the equipment.

2. Enhanced Tracking Tapered rollers aid in the alignment of products on the conveyor. Because they direct items towards the center of the conveyor line, they help prevent misalignment and reduce the risk of items falling off the conveyor, increasing overall safety.

3. Reduced Noise Levels The unique shape of tapered rollers can contribute to lower operational noise compared to standard rollers. This is particularly beneficial in settings where noise reduction is crucial, such as in food processing or packaging facilities.

4. Versatility Tapered conveyor rollers can handle various types of loads, from lightweight to heavier goods. Their design allows them to transition smoothly from one roller to another, making them suitable for different conveyor systems, including gravity conveyors and powered conveyors.

5. Cost-Effectiveness By reducing wear and operational issues, tapered rollers can lead to decreased maintenance costs and fewer replacements over time, making them a cost-effective choice for businesses heavily reliant on conveyor systems.

tapered conveyor rollers

Applications of Tapered Conveyor Rollers

The versatility of tapered conveyor rollers makes them suitable for a wide range of applications across various industries

- Warehouse and Distribution Centers Tapered rollers are widely used in warehouse environments for sorting and moving packages. Their ability to keep items aligned and reduce misdirection ensures efficient processing of goods.

- Manufacturing In manufacturing, tapered conveyor rollers can efficiently transport products along assembly lines, ensuring smooth transitions between different stages of production.

- Food and Beverage Industry The food industry benefits from tapered rollers due to their ability to reduce noise and enhance sanitation. Their design minimizes the possibility of contamination and makes cleaning easier.

- Packaging Tapered rollers play a crucial role in the packaging process, aiding in the movement of products from one stage to another seamlessly. Their tracking capabilities help maintain the integrity of packaged goods.

- E-commerce Fulfillment Centers With the rise of e-commerce, tapered conveyor rollers are increasingly used in fulfillment centers to automate the sorting and shipping processes. Their efficiency contributes significantly to the speed at which orders can be processed.

Conclusion

Tapered conveyor rollers provide significant advantages in material handling, enhancing the efficiency and reliability of various conveyor systems. Their unique design facilitates smoother movement, improved load distribution, and better tracking of goods, making them invaluable in numerous applications. As industries continue to evolve and the demand for efficient logistics grows, the role of tapered conveyor rollers in ensuring smooth operations will undoubtedly expand. Businesses seeking to optimize their conveyor systems should consider the implementation of tapered rollers to enhance performance and reduce costs in their operations.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025