Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Exploring the Mechanics and Applications of Pulley Tail Systems in Everyday Life

The Significance of Pulley Tails in Mechanical Systems

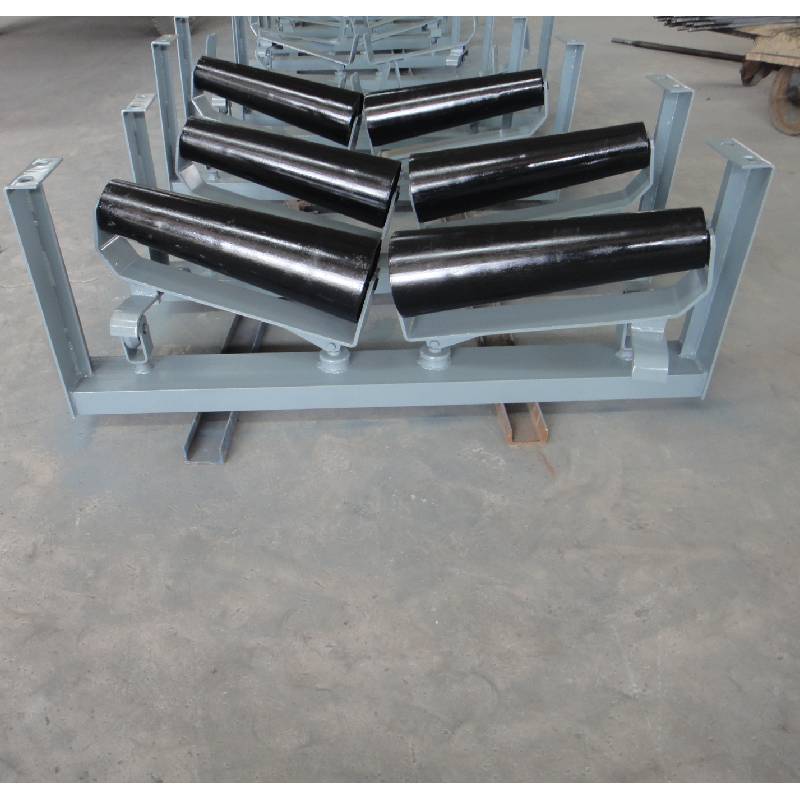

Pulley systems have been an integral part of mechanical engineering and various applications for centuries. Among the many components that contribute to the functionality of a pulley system, the pulley tail holds a significant yet often overlooked role. Understanding what a pulley tail is and its importance can provide insights into the efficiency and effectiveness of mechanical systems.

A pulley tail refers to the segment of rope, cable, or chain that extends beyond the pulley wheel. This portion serves multiple functions crucial for the proper operation of the pulley system. It provides the necessary length for attachment, allows for the adjustment of tension, and can even act as a safety mechanism in certain applications.

One of the primary functions of the pulley tail is to ensure that a load can be lifted or lowered effectively

. When a force is applied to the end of the pulley tail, it transmits that force through the pulley wheel, facilitating the movement of the attached load. The length of the tail is essential because it determines the mechanical advantage the system offers. In systems where you need to lift heavy weights, a longer tail can help distribute the weight more evenly, making the task easier and more efficient.pulley tail

Moreover, the pulley tail plays a crucial role in the tension management of the rope or cable used. In many applications, such as cranes or elevators, maintaining proper tension is vital for safety and operational efficiency. If the tension is too low, the load could slip, posing a severe risk to people or equipment nearby. Conversely, if the tension is too high, it may lead to excessive wear on the components or even failure of the system. By adjusting the pulley tail's length or the amount of cable it encompasses, operators can optimize the tension, ensuring smooth and safe operation.

In addition to load management and tension control, the pulley tail can also act as a safety feature. In many high-stakes environments, such as construction sites or industrial facilities, ensuring that loads are securely fastened and managed is essential. A well-maintained pulley tail can prevent accidental disengagement or dropping of loads, providing an additional layer of security. For instance, some systems employ safety catches or clamps on the pulley tail to keep it firmly in place, ensuring that the load remains stable during operation.

Beyond these practicalities, the design and maintenance of the pulley tail also reflect broader principles of engineering and physics. Engineers must consider factors such as material strength, friction, and wear when designing pulley systems. The pulley tail must be constructed from durable materials that can withstand repetitive motion and tension without degrading or breaking. Regular inspections and maintenance are crucial to identify potential faults early, allowing for timely repairs or replacements.

In conclusion, while the pulley tail may not receive the same level of attention as other components in a pulley system, its role is undeniably critical. From facilitating load movement and managing tension to providing safety and reliability, the pulley tail serves multiple functions that enhance the overall effectiveness of mechanical systems. As engineering continues to evolve, understanding and optimizing every aspect of pulley systems, including the often-overlooked pulley tail, will remain essential for achieving operational excellence. Whether in construction, manufacturing, or everyday applications, acknowledging the importance of this component contributes to a deeper appreciation of the mechanics at play in our world.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025