Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

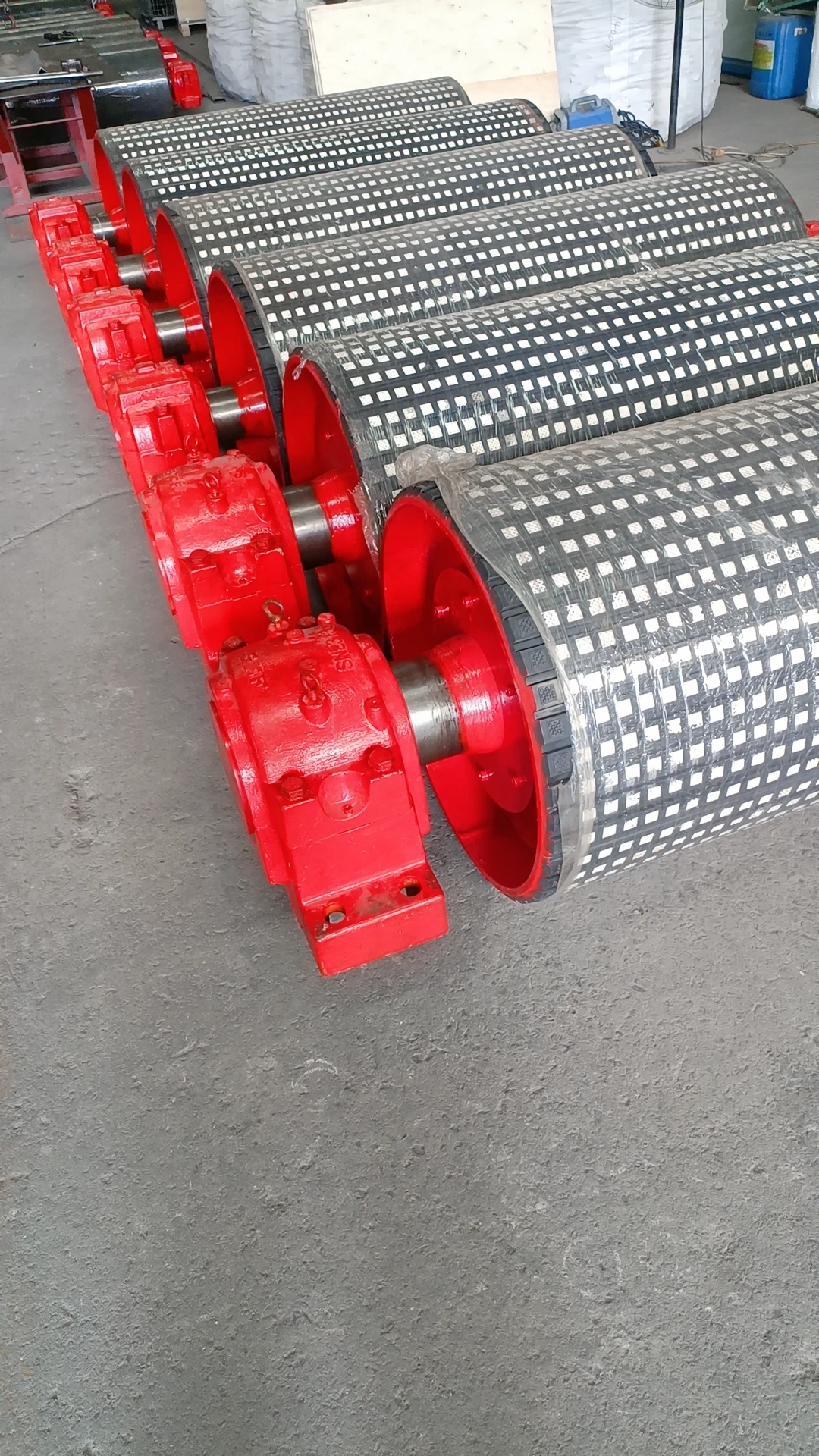

Zulu Polyurethane Application Rollers & Industrial Pulleys Durable Solutions

- Introduction to Polyurethane Roller Technology

- Technical Superiority in Material Engineering

- Performance Comparison: Market Competitor Analysis

- Customization Strategies for Industrial Needs

- Case Studies: Real-World Implementations

- Maintenance Protocols for Longevity

- Future Trends in Polyurethane Application Rollers

(polyurethane application roller)

Understanding Polyurethane Application Roller Fundamentals

Polyurethane application rollers have become indispensable across manufacturing sectors due to their unique molecular structure. With 40% higher shock absorption than traditional rubber variants, these components demonstrate 2.8x greater fatigue resistance in continuous operation scenarios. The cross-linked polymer chains enable:

- Dynamic load capacity up to 120kN/m²

- Operational temperature range (-40°C to 110°C)

- Surface hardness options from 50ShoreA to 75ShoreD

Engineering Advantages Over Conventional Materials

Comparative testing reveals polyurethane rollers achieve 18,000+ operating hours versus 6,500 hours for standard rubber equivalents. This durability stems from advanced compounding techniques that incorporate:

| Property | Polyurethane | Standard Rubber | Thermoplastic |

|---|---|---|---|

| Abrasion Resistance | 92% | 67% | 81% |

| Chemical Resistance | Class IV | Class II | Class III |

| Compression Set | 8% | 22% | 15% |

Industrial Adaptation Through Custom Design

Manufacturers now offer 12 parametric customization options including:

- Dual-density constructions (50-70 ShoreA gradient)

- Conductive formulations (10⁶-10¹² Ω·cm)

- FDA-compliant compositions for food processing

Implementation Success Stories

A packaging machinery OEM reported 34% throughput increase after switching to polyurethane lagging pulleys. Specific improvements included:

- Belt slippage reduction from 15% to 2.7%

- Maintenance intervals extended from 600 to 2,200 hours

Operational Longevity Enhancements

Proper maintenance extends service life beyond manufacturer guarantees. Key protocols involve:

- Monthly surface inspections using 20x magnification

- Quarterly hardness verification (±3 ShoreA tolerance)

- Annual dynamic balancing checks

Innovating Polyurethane Roller Applications

Emerging composite formulations now enable polyurethane rollers to handle 45% higher rotational speeds while maintaining dimensional stability. Recent advancements include:

- Nano-reinforced matrices for aerospace conveyors

- Self-lubricating grades reducing coefficient of variation to 0.18

(polyurethane application roller)

FAQS on polyurethane application roller

Q: What are the primary uses of a polyurethane application roller?

A: Polyurethane application rollers are ideal for coating, laminating, and transferring materials due to their durability, chemical resistance, and precise surface finish capabilities.

Q: Why choose a polyurethane pulley (polyurethane lagging pulley) over traditional options?

A: Polyurethane pulleys reduce slippage, minimize wear on belts, and extend equipment lifespan, making them perfect for high-tension conveyor or drive systems.

Q: How does a polyurethane rubber roller differ from other roller materials?

A: Polyurethane rubber rollers offer superior abrasion resistance, tear strength, and load-bearing capacity compared to standard rubber or metal rollers, ensuring longevity in harsh environments.

Q: Can polyurethane rollers be maintained for extended performance?

A: Yes, regular cleaning, avoiding extreme temperatures, and inspecting for surface damage can significantly prolong the service life of polyurethane rollers.

Q: In which industries are polyurethane rollers and pulleys commonly applied?

A: They are widely used in manufacturing, printing, packaging, material handling, and automotive industries for tasks requiring precision, flexibility, and resistance to wear.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025