Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Optimizing Feeder Idler Systems for Enhanced Performance and Efficiency

Understanding Feeder Idlers in Material Handling

In the realm of industrial material handling, the feeder idler plays a crucial role in the efficiency and effectiveness of conveyor systems. These components, often unassuming in appearance, serve important functions that facilitate the seamless movement of materials from one point to another. This article explores the significance of feeder idlers, their design, applications, and the impact they have on overall system performance.

What is a Feeder Idler?

A feeder idler is a type of roller used in conveyor systems that aids in the distribution and transportation of bulk materials. Typically positioned at the loading point of a conveyor, these idlers are designed to support the belt and maintain its alignment while carrying heavy loads. The primary function of a feeder idler is to help control the flow of materials onto the conveyor belt, ensuring an even distribution that optimizes handling efficiency.

Design and Construction

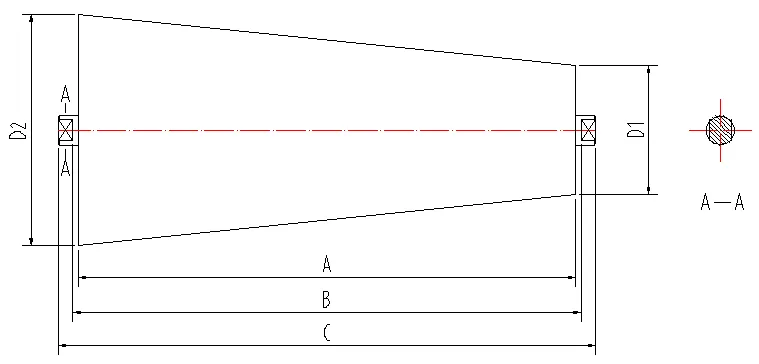

Feeder idlers come in various designs, depending on the specific needs of the application. They are generally constructed from durable materials such as steel or heavy-duty plastic to withstand the harsh conditions of material handling environments. The rollers can be designed with different diameters and widths, allowing them to accommodate various belt sizes and types of materials.

In many cases, feeder idlers incorporate features such as self-aligning capabilities and impact resistance. Self-aligning idlers help maintain the correct positioning of the conveyor belt, which is critical for preventing misalignment and reducing wear on the belt and other components. Impact-resistant features are essential in applications where heavy or abrasive materials are handled, as they mitigate the risks of damage to both the idler and the conveyor system.

Applications of Feeder Idlers

feeder idler

Feeder idlers are widely used across various industries, including mining, construction, agriculture, and recycling. In mining operations, for example, feeder idlers are essential for transporting minerals and aggregates from extraction sites to processing facilities. Their ability to handle large volumes of material efficiently makes them invaluable in these heavy-duty applications.

In agriculture, feeder idlers are used in grain handling systems where they facilitate the movement of grains from storage to processing machines. Their design helps prevent spillage and ensures that the materials move smoothly and evenly, optimizing throughput.

The recycling industry also benefits significantly from feeder idlers, as they help convey a diverse range of materials, from metals to plastics, in a way that enhances sorting and separation processes. The versatility of feeder idlers in accommodating different materials and conditions makes them a vital component in modern recycling operations.

Efficiency and Performance Impact

The role of feeder idlers in enhancing the efficiency of conveyor systems cannot be overstated. By maintaining the proper alignment and flow of materials, these components reduce the chances of bottlenecks and delays that could hinder operations. When feeder idlers are functioning optimally, the entire material handling system runs more smoothly, leading to increased productivity and reduced operational costs.

Furthermore, proper maintenance of feeder idlers is crucial in preserving their performance. Regular inspections and timely replacements can prevent unforeseen breakdowns that could disrupt production. Investing in high-quality feeder idlers and implementing a maintenance schedule can significantly enhance the longevity and reliability of conveyor systems.

Conclusion

In conclusion, feeder idlers are an integral part of modern material handling systems, offering essential support and efficiency in the transportation of bulk materials. Their design and functionality cater to various industrial applications, making them indispensable in sectors ranging from mining to agriculture. By prioritizing their maintenance and understanding their importance, organizations can improve their material handling operations, paving the way for enhanced productivity and success in the ever-evolving industrial landscape.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025