Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor trough rollers

The Importance of Conveyor Trough Rollers in Material Handling

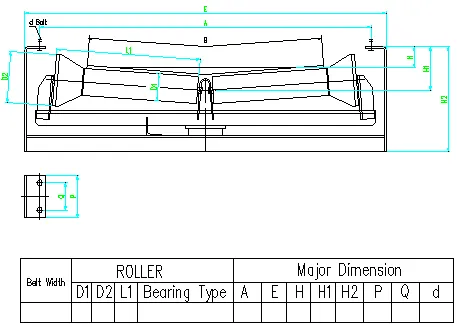

Conveyor systems are an essential component of material handling in a variety of industries, including mining, manufacturing, and logistics. Among the various components involved in these systems, conveyor trough rollers play a critical role in ensuring the efficiency and reliability of material transport. This article explores the significance of conveyor trough rollers, their design, functionality, and the impact they have on overall operational efficiency.

What Are Conveyor Trough Rollers?

Conveyor trough rollers are cylindrical components mounted on a frame, forming part of a conveyor belt system. Their primary function is to support the conveyor belt while allowing it to move freely. Unlike flat rollers, trough rollers are designed to hold the conveyor belt in a concave shape, which is particularly effective for transporting loose materials such as coal, gravel, and sand. The trough design helps to contain the material during transit, minimizing spillage and ensuring a more efficient loading and unloading process.

Design Features

The design of conveyor trough rollers can vary based on their intended application. Typically, they come in various diameters and lengths, accommodating different types of conveyor systems. High-quality materials such as steel or heavy-duty plastic are often used to manufacture these rollers, providing enhanced durability and resistance to wear and tear. Some trough rollers are equipped with sealed bearings, which help reduce maintenance costs by preventing dirt and dust from entering the roller assembly, thus prolonging its service life.

Functional Benefits

1. Material Containment The trough shape of the rollers ensures that loose materials stay put during transport, reducing the likelihood of spillage and loss of valuable resources. This containment is essential in industries where materials are costly, such as mining.

conveyor trough rollers

2. Reduced Friction Utilizing high-quality bearings and precision engineering, conveyor trough rollers minimize friction, thereby reducing the energy required to move the conveyor belt. This efficiency translates into cost savings, as less energy consumption leads to lower operational costs.

3. Load Distribution Trough rollers contribute to even load distribution across the conveyor belt. This feature helps to prevent excessive wear and stress on specific areas of the belt, thereby extending the lifespan of both the rollers and the belt.

4. Versatility Conveyor trough rollers are versatile and can be used in various configurations, allowing for adaptability in different industry settings. They can be installed in inclined, declined, or horizontal conveyors, making them suitable for diverse applications.

Impact on Operational Efficiency

The integration of conveyor trough rollers in material handling systems significantly enhances operational efficiency. By ensuring smooth and reliable transportation of materials, these rollers contribute to faster production cycles and reduced downtime. The consistent performance of trough rollers leads to less maintenance and fewer replacements, allowing businesses to allocate resources more effectively.

Moreover, the ability to contain and transport materials efficiently means that companies can meet production demands without significant delays. This reliability is crucial in competitive industries where timely delivery is paramount.

Conclusion

In conclusion, conveyor trough rollers are indispensable components of modern material handling systems. Their design, functionality, and numerous benefits make them vital for maintaining operational efficiency in various industries. By investing in high-quality conveyor trough rollers, businesses can enhance their material handling capabilities, leading to improved productivity, reduced costs, and increased competitiveness in the market. As industries continue to evolve, the role of these conveyor components will only grow in importance, reinforcing their place as a cornerstone of effective material transport solutions.

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025