Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

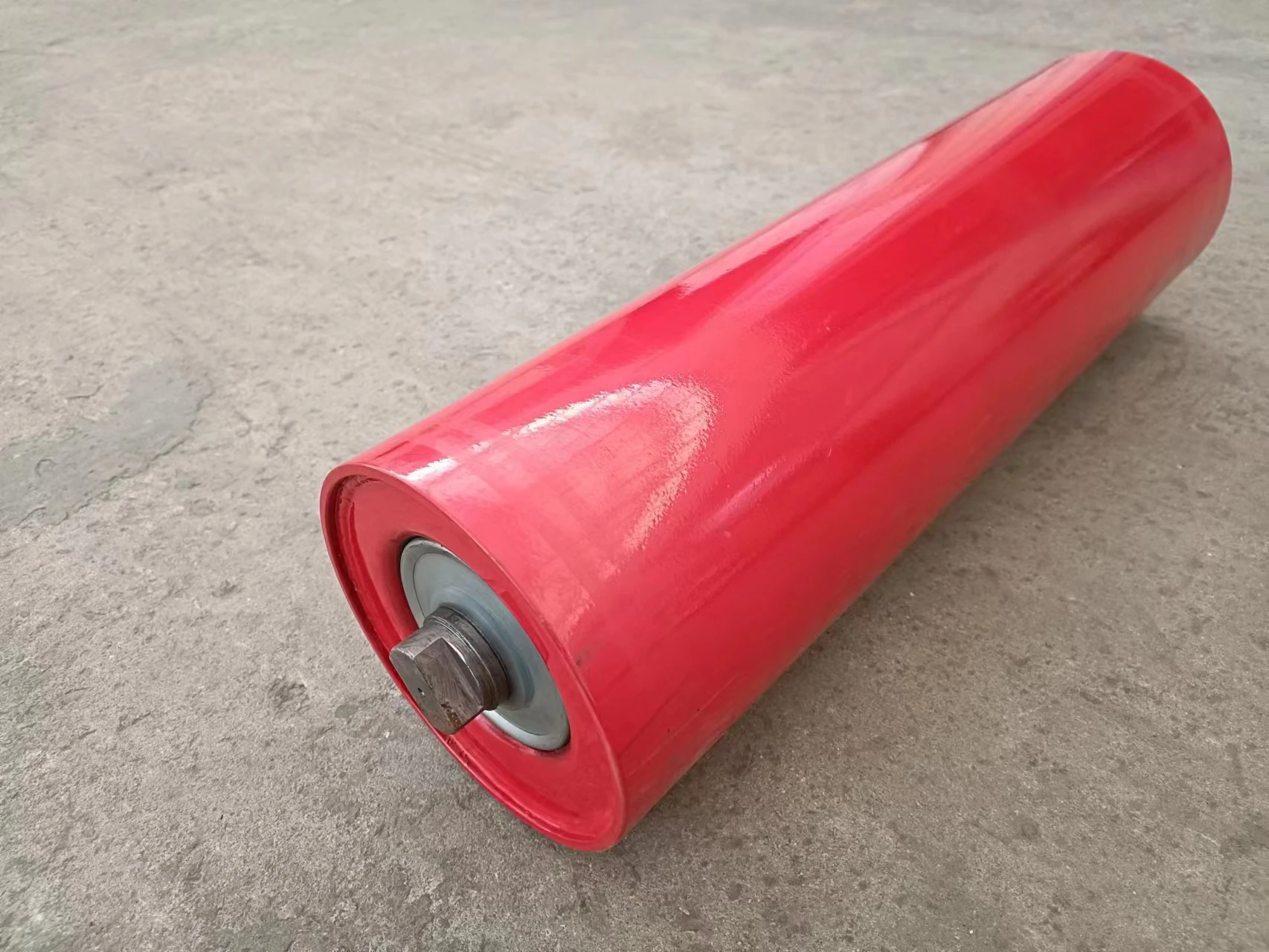

Zulu conveyor take up assembly

Understanding Conveyor Take-Up Assemblies A Key Component in Material Handling

Conveyor systems are integral to material handling in various industries, including manufacturing, mining, and logistics. Among the critical components of these systems is the conveyor take-up assembly. This assembly plays a pivotal role in the proper functioning of conveyor belts, ensuring efficiency and longevity.

Understanding Conveyor Take-Up Assemblies A Key Component in Material Handling

There are two main types of take-up assemblies manual and automatic. Manual take-ups require operators to make adjustments manually, which can be labor-intensive and time-consuming. Typically, these systems include a winch or tensioning mechanism that allows workers to tighten or loosen the belt as needed. While more straightforward, this approach may not always guarantee consistent tension, particularly in high-usage applications.

conveyor take up assembly

In contrast, automatic take-up systems utilize sophisticated technology, including sensors and motors, to monitor and adjust the belt tension continuously. These systems provide real-time feedback and can make adjustments without human intervention, significantly increasing efficiency and reducing the need for manual labor. Automatic systems are particularly beneficial in environments where belts operate under heavy loads or in demanding conditions.

The design of a conveyor take-up assembly can vary based on the specific requirements of the application. Some assemblies may include gravity take-ups, where a weight is used to apply tension, while others may feature hydraulic or pneumatic systems for more sensitive applications. The choice of take-up design often depends on factors such as the type of materials being transported, the length of the conveyor, and the potential for changes in the load.

Proper maintenance of the conveyor take-up assembly is essential for ensuring the longevity of the conveyor system. Regular inspections should be conducted to check for signs of wear, misalignment, and proper operation of the tensioning mechanism. Additionally, bearings and other moving parts should be lubricated as part of routine maintenance to minimize friction and prevent premature failure.

In conclusion, the conveyor take-up assembly is an essential component of conveyor systems that ensures optimal belt tension and operational efficiency. By understanding its importance and ensuring proper maintenance, companies can enhance the performance of their material handling systems and avoid costly downtimes. As industries continue to evolve and demand for efficient material handling solutions grows, the role of the conveyor take-up assembly will remain vital in supporting these advancements.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025