Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

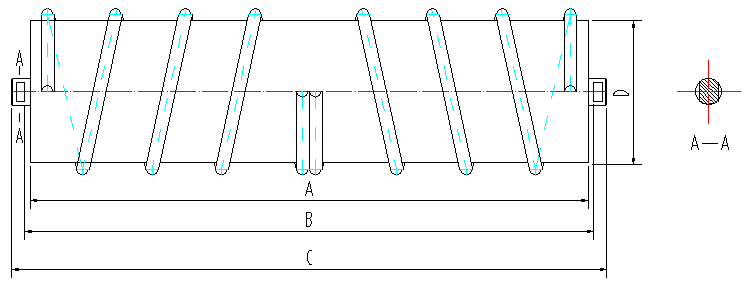

Zulu conveyor side guide

Understanding Conveyor Side Guides Importance and Functionality

Conveyor systems are an essential part of countless industries, offering efficient movement of materials and products. Among the various components that contribute to the effective operation of these systems, conveyor side guides play a crucial role. This article will explore the importance of side guides, their functionality, types, and best practices for their implementation.

What are Conveyor Side Guides?

Conveyor side guides are accessories that help to keep products or materials centered on the conveyor belt as they move from one point to another. These guides are typically installed along the sides of a conveyor system and serve to prevent items from drifting off the belt, ensuring smooth and uninterrupted operation. Whether in a packaging line, assembly area, or distribution center, side guides are integral to maintaining the efficiency of conveyance processes.

Importance of Side Guides

The primary function of conveyor side guides is to enhance the efficiency and safety of conveyor operations. By preventing materials from slipping off the sides of the belt, side guides reduce the chances of product damage and loss, ensuring that goods reach their destination intact. Additionally, side guides help in minimizing workplace accidents by keeping materials contained, reducing the risk of employees tripping over stray items that may fall off the conveyor.

Moreover, side guides contribute to the smooth flow of operations. In environments where products of varying sizes are being transported, adjustable side guides can adapt to accommodate different dimensions, making the conveyor system versatile and functional across numerous applications. This adaptability is particularly valuable in industries such as food processing, packaging, and automotive where production runs may frequently change.

Types of Side Guides

There are several types of conveyor side guides, each designed to meet specific operational needs

1. Fixed Guides These guides are stationary and are typically used for consistent product sizes. They ensure a set path for standard items without the need for adjustments.

conveyor side guide

2. Adjustable Guides These can be customized according to the width of the product being transported. Adjustable guides are ideal for systems that handle varying product sizes and require flexibility.

3. Cushioned Guides These guides feature a soft material that provides additional support and protection for delicate items, minimizing the risk of damage.

4. Guide Rails These extend higher than standard guides and can provide more robust support for larger or heavier items, particularly in high-speed conveyor systems.

Best Practices for Implementation

To maximize the effectiveness of conveyor side guides, consider these best practices

- Regular Maintenance Inspect side guides regularly for wear and tear. Damaged guides can undermine their effectiveness, and timely replacement is crucial.

- Proper Installation Install side guides according to manufacturer specifications to ensure they function correctly. Improper installation can lead to misalignment and decreased performance.

- Adaptability Whenever possible, choose adjustable side guides to accommodate a wide range of products. This flexibility can save time and enhance operational efficiency.

- Material Selection Select side guides made from durable materials that can withstand the specific conditions of your operational environment, such as temperature changes or exposure to chemicals.

In conclusion, conveyor side guides are indispensable components that enhance the efficiency, safety, and adaptability of conveyor systems. By understanding their importance and implementing best practices, industries can significantly improve their productivity and operational reliability. Investing in the right side guide solutions can lead to smoother processes and a safer work environment, ultimately supporting business growth and success.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025