Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

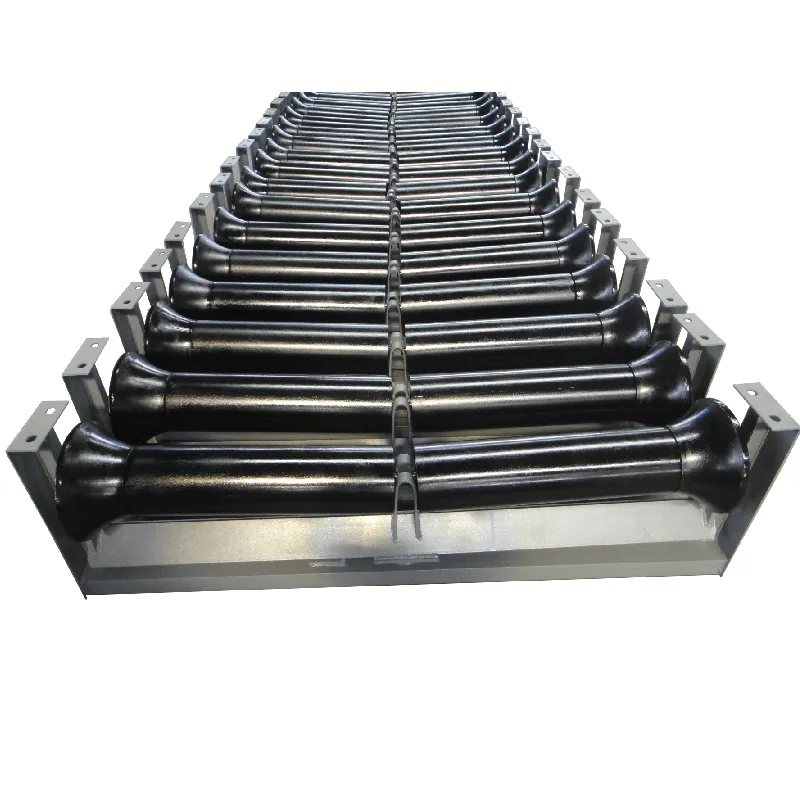

Zulu Conveyor Roller Support Bracket for Enhanced Material Handling Efficiency

Understanding Conveyor Roller Brackets An Essential Component in Material Handling Systems

In the realm of industrial logistics and material handling, conveyor systems play a pivotal role in enhancing efficiency and safety. At the heart of these systems lies a crucial component known as the conveyor roller bracket. Understanding the significance, design, and application of conveyor roller brackets can shed light on their vital role in conveyor systems.

What is a Conveyor Roller Bracket?

A conveyor roller bracket is a mechanical component designed to support and hold the rollers that facilitate the movement of goods along a conveyor system. These brackets are essential in maintaining the structural integrity of the conveyor line. They allow for smooth transitions of materials, ensuring that items can be transported safely from one point to another with minimal friction and disruption.

Importance of Conveyor Roller Brackets

1. Support and Stability The primary function of a conveyor roller bracket is to provide robust support and stability to the rollers. They ensure that the rollers are correctly positioned, allowing them to rotate freely while bearing the weight of the conveyed materials. This stability is crucial in preventing roller misalignment that can lead to jammed conveyors or even equipment damage.

2. Load Distribution Conveyor roller brackets are designed to evenly distribute the weight of the items being transported across the conveyor system. This load distribution helps in prolonging the life of both the rollers and the conveyor structure, ultimately reducing maintenance costs and downtime.

3. Ease of Maintenance Many conveyor roller brackets come with features that facilitate easy maintenance. Whether by allowing quick access to replace worn-out rollers or through designs that enable straightforward adjustments, these brackets are crucial for keeping conveyor systems running efficiently.

4. Versatility Conveyor roller brackets can be used in a variety of conveyor systems, including belt conveyors, gravity conveyors, and more. They can accommodate different roller types and sizes, making them a versatile choice for various industrial applications.

conveyor roller bracket

Design and Materials

Conveyor roller brackets are typically manufactured from durable materials such as steel, aluminum, or high-strength plastic. Steel brackets are favored for their strength and durability, especially in heavy-duty applications, while aluminum offers a lightweight alternative that does not compromise on performance. The choice of material often depends on the specific application, weight of materials being handled, and environmental conditions.

The design of these brackets can vary significantly based on the type of conveyor system. Some common designs include fixed brackets, adjustable brackets, and cantilever brackets. Each design serves a unique purpose, whether it’s allowing for height adjustments or providing additional support for heavy loads.

Applications Across Industries

Conveyor roller brackets can be found in myriad industries, reflecting their essential role in material handling. In manufacturing, they are critical for assembly lines where multiple components need to be moved seamlessly. In warehousing and distribution, conveyor systems equipped with quality roller brackets facilitate the quick movement of goods, enhancing productivity and reducing shipping times.

Additionally, the mining and agricultural sectors utilize conveyor roller brackets for transporting bulk materials, such as minerals or grain. In the food industry, conveyor systems are used to process and package food items, where hygiene and operational efficiency are paramount, making robust roller brackets essential.

Conclusion

In conclusion, conveyor roller brackets may be small components within a much larger material handling system, but their contribution is significant. By providing essential support, ensuring smooth operation, and enabling ease of maintenance, these brackets play a crucial role in the efficiency and reliability of conveyor systems across various industries. Understanding their importance and design can help businesses make informed decisions when selecting and maintaining their conveyor systems, ultimately leading to improved productivity and reduced operational costs. As industries continue to advance and innovate, the conveyor roller bracket will remain a cornerstone of effective material handling solutions.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025