Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Conveyor Components Durable Parts & Custom Solutions [Company Name]

- The Crucial Role of Conveyor Components in Material Handling Systems

- Performance Metrics: Data-Driven Impact of Premium Components

- Engineering Superiority: Technical Advantages of Modern Conveyor Parts

- Market Analysis: Comparing Leading Conveyor Component Manufacturers

- Custom Engineering Solutions for Specific Industry Requirements

- Implementation Cases: Success Stories Across Diverse Sectors

- Future-Proofing Operations with Strategic Component Partners

(conveyor component)

The Crucial Role of Conveyor Components in Material Handling Systems

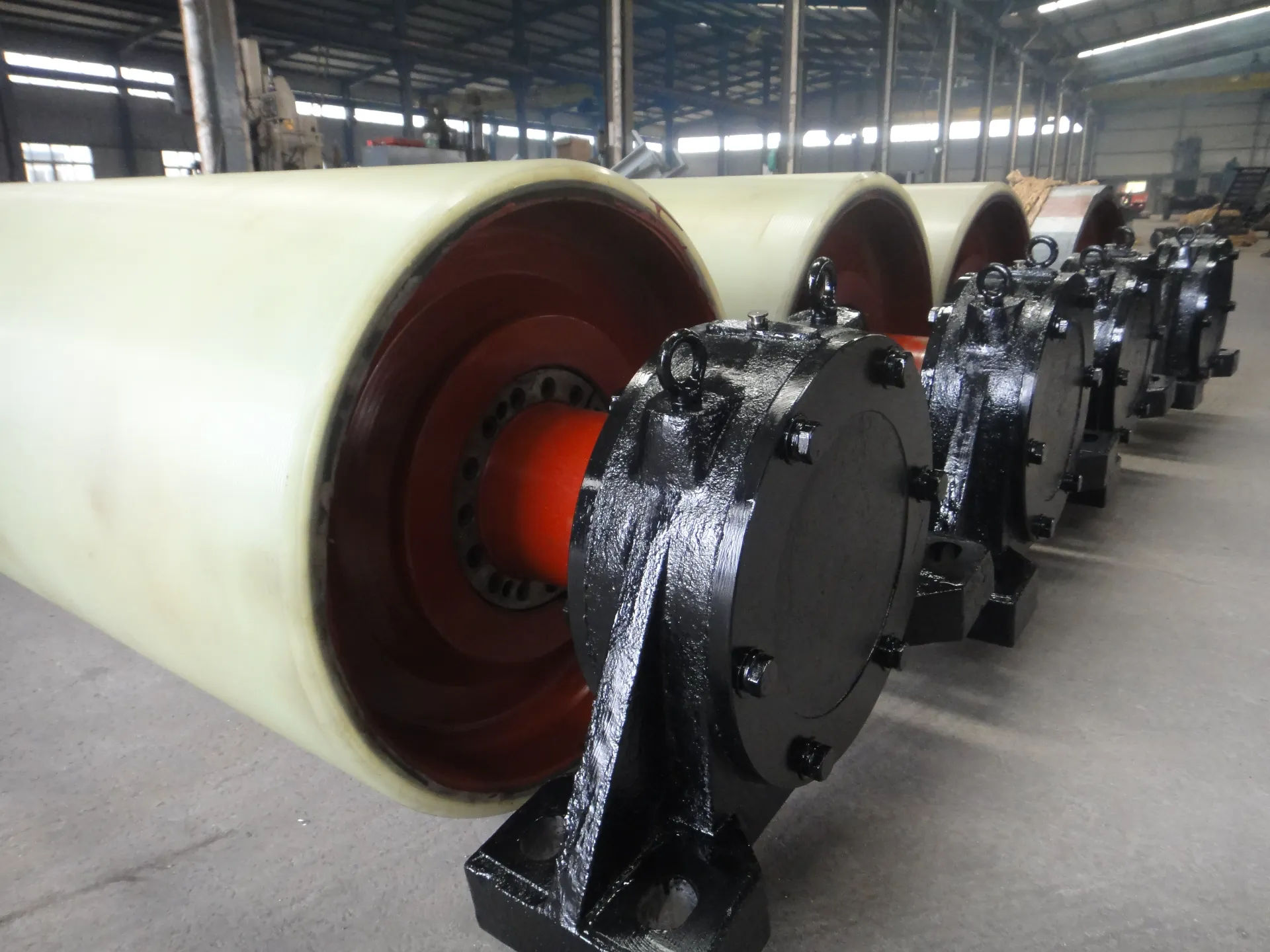

Industrial operations rely heavily on robust material transport systems where conveyor component

s serve as fundamental building blocks. These elements - from rollers and idlers to belts and fasteners - directly influence operational continuity and safety. Operations managers recognize that component failures cause 63% of unplanned downtime in material handling environments, highlighting their critical function beyond mere point-to-point transfer. The strategic selection of conveyor belt accessories suppliers directly affects throughput velocity, energy consumption profiles, and maintenance expenditure cycles across manufacturing plants and distribution centers.

Performance Metrics: Data-Driven Impact of Premium Components

Quantitative analysis reveals how optimized conveyor elements drive measurable operational improvements. Systems using wear-resistant pulleys demonstrate 28% lower replacement frequency over standard alternatives according to bulk handling industry reports. Enhanced tracking rollers reduce material spillage by 19-37% while dynamic impact beds extend belt service life by 30%. Field tests conducted across European mining sites show that precision-engineered idlers decrease rotational resistance by up to 28%, cutting energy requirements significantly. These quantifiable advantages position premium components as operational investments rather than expense line items.

Engineering Superiority: Technical Advantages of Modern Conveyor Parts

Technical innovations separate high-performance conveyor components from commodity alternatives. Advanced bearings featuring triple-labyrinth seals maintain lubrication integrity in particulate-heavy environments where standard bearings fail within months. Polymer-composite rollers with stainless steel shafts withstand corrosive processing areas while reducing noise pollution by 6-8 decibels. Smart integration capabilities now allow monitoring of vibration signatures, temperature thresholds, and alignment deviations through embedded sensors. These technological improvements culminate in enhanced durability ratings – premium cleated belts offer 240% longer service life in abrasive applications compared to conventional versions.

Market Analysis: Comparing Leading Conveyor Component Manufacturers

| Manufacturer | Lead Time | Durability Rating | Customization Scope | Price Index |

|---|---|---|---|---|

| Global Belt Solutions | 3-5 days | 96% operational reliability | Full system retrofits | 15% premium |

| Precision Conveyor Parts | 7-14 days | 91% operational reliability | Component modifications | Industry average |

| Reliable Hardware Systems | 2-4 days | 87% operational reliability | Limited alterations | 8% below average |

| Industrial Dynamics Group | 10-21 days | 94% operational reliability | Complete custom builds | 22% premium |

Custom Engineering Solutions for Specific Industry Requirements

Forward-thinking conveyor component companies excel at developing application-specific solutions that go beyond catalog offerings. Food processing operations benefit from FDA-compliant belt materials resistant to extreme sanitation protocols while avoiding microbial growth surfaces. Mining applications utilize tungsten-reinforced scraper blades capable of handling 5-ton hourly aggregate loads. Recent innovations include static-dissipative components for explosive environments and magnetic belt inserts for ferrous material separation. Such tailored approaches often yield 31-45% higher efficiency versus generic implementations, transforming conveyor infrastructure into competitive advantages.

Implementation Cases: Success Stories Across Diverse Sectors

A prominent automotive manufacturer reduced conveyor-related stoppages by 72% after overhauling 3.2km of assembly line transport with impact-resistant rollers and synchronized belt modules. Cement producers report 860 fewer maintenance hours annually after upgrading to ceramic-reinforced idlers across raw material feed systems. Third-party analysis confirms that warehouse operations decreased energy usage by 19% through implementation of low-friction guidance components. These documented cases consistently validate that strategic conveyor infrastructure investments deliver measurable productivity gains regardless of sector dynamics.

Future-Proofing Operations with Strategic Component Partners

Selecting the appropriate conveyor belt accessories suppliers represents a pivotal operational decision with long-term implications. The strongest conveyor component relationships deliver value beyond transactional supply arrangements through joint process optimization initiatives and predictive maintenance planning. Partnering with providers who maintain component compatibility archives for legacy systems offers particular advantages during phased upgrades. Forward-looking operations establish component testing protocols to verify performance claims before implementation. This strategic approach ensures continuous material flow while building resilient, adaptable infrastructure ready for evolving industrial challenges.

(conveyor component)

FAQS on conveyor component

Q: What factors should I consider when choosing a conveyor component company?

A: Prioritize expertise, industry certifications, and customer reviews. Ensure they offer components compatible with your conveyor system type. Timely delivery and after-sales support are also critical.

Q: What are common conveyor belt accessories supplied by manufacturers?

A: Common accessories include belt cleaners, tracking systems, fasteners, and impact beds. These enhance conveyor efficiency and lifespan. Suppliers often customize solutions for specific operational needs.

Q: How do I maintain conveyor components for optimal performance?

A: Regularly clean debris and inspect for wear or misalignment. Lubricate moving parts as per guidelines. Replace damaged components promptly to avoid system downtime.

Q: Can conveyor component suppliers provide custom-designed parts?

A: Yes, many companies offer custom fabrication based on load capacity, material type, or environmental conditions. Share technical specifications upfront to ensure precise solutions.

Q: What industries rely heavily on conveyor belt accessories suppliers?

A: Mining, manufacturing, logistics, and food processing industries are key users. These sectors require durable, hygienic, or high-speed conveyor systems tailored to their workflows.

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025